Abstract

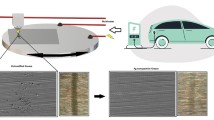

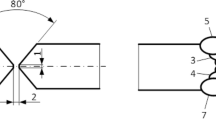

This article summarizes the mechanics of two mechanical fatigue methods, cyclic bending fatigue and shear fatigue, in inducing failure in solder joints in package assemblies, and it presents the characteristics of fatigue failures resulting from these methods using example cases of Sn-Pb eutectic and Sn-rich Pb-free solder alloys. Numerical simulation suggests that both testing configurations induce fatigue failure by the crack-opening mode. In the case of bending fatigue, the strain induced by the bending displacement is found to be sensitive to chip geometry, and it induces fatigue cracks mainly at the solder matrix adjacent to the printed circuit board interface. In case of shear fatigue, the failure location is firmly fixed at the solder neck, created by solder mask, where an abrupt change in the solder geometry occurs. Both methods conclude that the Coffin–Manson model is the most appropriate model for the isothermal mechanical fatigue of solder alloys. An analysis of fatigue characteristics using the frame of the Coffin–Manson model produces several insightful results, such as the reason why Pb-free alloys show higher fatigue resistance than Sn-Pb alloys even if they are generally more brittle. Our analysis suggests that it is related to higher work hardening. All these results indicate that mechanical fatigue can be an extremely useful method for fast screening of defective package structures and also in gaining a better understanding of fatigue failure mechanism and prediction of reliability in solder joints.

Similar content being viewed by others

References

K. Harr, C.B. Lee, Y.S. Kim, S.W. Park, J.G. Kim, and Y. Kweon, ECS Trans. 44, 975 (2012).

J.H. Lau, Solder. Surf. Mount Technol. 16, 12 (2004).

J.H. Lau, IEEE Trans. Compon. Packag. Manuf. Technol. B 19, 728 (1996).

K. Zeng and K.N. Tu, Mater. Sci. Eng. R 38, 55 (2002).

E.H. Wong, S.K.W. Seah, and V.P.W. Shim, Microelectron. Reliab. 48, 1747 (2008).

B. Wang, J.J. Li, A. Gallagher, J. Wrezel, P. Towashirporn, and N.Q. Zhao, Microelectron. Reliab. 52, 1475 (2012).

J. Karppinen, J. Li, J. Pakarinen, T.T. Mattila, and M.P. Kröckel, Microelectron. Reliab. 52, 190 (2012).

S.J. Jeon, J.W. Kim, B. Lee, H.J. Lee, S.B. Jung, S. Hyun, and H.J. Lee, Microelectron. Eng. 91, 147 (2012).

X.J. Fan, A.S. Ranouta, and H.S. Dhiman, IEEE Trans. Compon. Packag. Manuf. Technol. 3, 53 (2013).

Y. Yao and L.M. Keer, Microelectron. Reliab. 53, 629 (2013).

J. Hokka, J. Li, T.T. Mattila, and M.P. Kröckel, Microelectron. Reliab. 52, 1445 (2012).

H. Yu, N. GmbH, U. Germany, and D.K. Shangguan, Solder. Surf. Mount Technol. 25, 31 (2013).

H.T. Lee, H.S. Lin, C.S. Lee, and P.W. Chen, Mater. Sci. Eng. A 407, 36 (2005).

D.A.A. Shnawah, S.B.M. Said, M.F.M. Sabri, I.A. Badruddin, and F.X. Che, Mater. Sci. Eng. A 551, 160 (2012).

D. Shangguan, Lead-Free Solder Interconnect Reliability (Materials Park, OH: ASM International, 2005).

K.J. Puttlitz and K.A. Stalter, Handbook of Lead-Free Solder Technology for Microelectronic Assemblies (New York: Marcel Dekker, 2004).

Y. Li, K.S. Moon, and C.P. Wong, Science 308, 1419 (2005).

A.Z. Miric, Soldering and Surface Mount Technology (Bradford, UK: MCB University Press, 1998), p. 19.

D.A. Shnawah, M.F.M. Sabri, and I.A. Badruddin, J. Microelectron. Electron. Compon. Mater. 4, 3 (2013).

W.H. Chen, C.F. Yu, H.C. Cheng, Y.M. Tsai, and S.T. Lu, Microelectron. Reliab. 53, 30 (2013).

W. Leea, L.T. Nguyena, and G.S. Selvaduray, Microelectron. Reliab. 40, 231 (2000).

J.H.L. Pang, D.Y.R. Chong, and T.H. Low, IEEE Trans. Compon. Packag. Manuf. Technol. 24, 705 (2001).

D.A. Shnawah, M.F.M. Sabri, and I.A. Badruddin, Microelectron. Reliab. 52, 90 (2012).

G. Khatibi, W. Wroczewski, B. Weiss, and H. Ipser, Microelectron. Reliab. 49, 1283 (2009).

Z.W. Zhong and T.Y. Tee, Proc. IEEE 97, 175 (2009).

A. Syed, Proc. 54th Electron. Compon. Technol. Conf. (Piscataway, NJ: IEEE, 2004), pp. 737–746.

D. Herkommer, J. Punch, and M. Reid, Microelectron. Reliab. 50, 116 (2010).

H. Wei and K. Wang, J. Electron. Mater. 40, 2314 (2011).

W.H. Bang, C.U. Kim, H.T. Ma, and T.K. Lee, Proc. Electron. Compon. Technol. Conf. (Piscataway, NJ: IEEE, 2012), pp. 2070–2074.

H.L. Xu, W.H. Bang, C.U. Kim, and T.K. Lee, Proc. Electron. Compon. Technol. Conf. (Piscataway, NJ: IEEE, 2012), pp. 484–489.

Y. Zhao, C. Basaran, A. Cartwright, and T, Dishongh, International Society Conference on Thermal Phenomena, 174 (2000).

T.K. Lee, H.T. Ma, K.C. Liu, and J. Xue, J. Electron. Mater. 39, 2564 (2010).

J.D. Krupp, W.A. Brantley, and H. Gerstein, J. Endod. 10, 372 (1984).

W.H. Bang, M.W. Moon, C.U. Kim, S.H. Kang, J.P. Jung, and K.H. Oh, J. Electron. Mater. 37, 417 (2008).

X.Q. Shi, H.L.J. Pang, W. Zhou, and Z.P. Wang, Int. J. Fatigue 22, 217 (2000).

H.L. John, B.S. Xiong, and T.H. Low, Int. J. Fatigue 26, 865 (2004).

J.D. Morrow, ASTM-STP 378, 45 (1965).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, CU., Bang, WH., Xu, H. et al. Characterization of Solder Joint Reliability Using Cyclic Mechanical Fatigue Testing. JOM 65, 1362–1373 (2013). https://doi.org/10.1007/s11837-013-0720-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-013-0720-2