Abstract

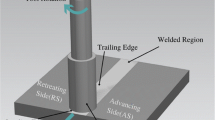

Friction stir processing (FSP) is a novel process developed based on the principle of friction stir welding (FSW) that locally manipulates the microstructure by imparting a high level of energy in the solid state resulting in improved mechanical properties. Additionally, FSP has emerged as an advanced tool to produce surface composites by embedding second phase particles into the matrix. Our work to date has shown that FSP can be implemented as a post-casting method to locally eliminate casting defects, such as porosity due to gas evolution during casting. Coarse second phases are broken up into fine nearly equiaxed particles and distributed uniformly in the matrix; grain refinement is also attained by dynamic recrystallization during FSP. This results in improved mechanical properties. Furthermore, our work shows that friction stir processing is a viable means of producing localized composite zones in cast Al components. Such improvements have important implications for manufactured components for diesel engines and for critical and high integrity components. The convenience of FSP as a post-processing step that can easily be carried out during machining operation makes it quite attractive for adoption.

Similar content being viewed by others

References

W.M. Thomas, E.D. Nicholas, J.C. Needham, M.G. Murch, P. Templesmith, and C.J. Dawes, GB Patent Application No. 9,125,978 (8 December 1991).

W. Wang, Q. Shi, P. Liu, H. Li, and T. Li, J. Mater. Proc. Technol., 209 (2009), p. 2099.

R.D. Doherty, D.A. Hughes, F.J. Humphreys, J.J. Jonas, D.J. Jensen, M.E. Kassner, W.E. King, T.R. Mc-Nelley, H.J. McQueen, and A.D. Rollett, Mater. Sci. and Eng. A, 238 (1997), p. 219.

Z.Y. Ma, R.S. Mishra, and M.W. Mahoney, Acta Mater., 50 (2002), p. 4419.

Y. Zhao, S. Lin, and L. Wu, Materials Letters, 59 (2005), p. 2948.

I. Charit and R.S. Mishra, Mater. Sci. and Eng. A, 359 (2003), p. 290.

I. Charit, R.S. Mishra, and M.W. Mahoney, Scripta Mater., 47 (2002), p. 631.

P. Cavaliere and P.P. DeMarco, Mater. Sci. and Eng. A, 462 (2007), p. 206.

A.P. Reynolds, Scripta materialia, 58 (2008), p. 338.

Z.Y. Ma, S.R. Sharma, and R.S. Mishra, Metall. Mater. Trans. A, 37A (2006), p. 3323.

J.Q. Su, T.W. Nelson, and C.J. Sterling, Philosophical Magazine, 86 (2006), p. 1.

ASM Handbook, Volume 4, Heat Treating (Materials Park, OH: ASM International, 1991).

J. Dennis, P.S. Bate, and F.J. Humphreys, Acta materialia, 57 (2009), p. 4539.

I. Charit and R.S. Mishra, Scripta materialia, 58 (2008), p. 367.

D.C. Hofmann and D.S. Vecchio, Mater. Sci. and Eng. A, 465 (2007), p. 165.

A.H. Feng, B.L. Xiao, and Z.Y. Ma, Comp. Sci. Technol., 68 (2008), p. 2141.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, N., Apelian, D. Friction stir processing of aluminum cast alloys for high performance applications. JOM 63, 44–50 (2011). https://doi.org/10.1007/s11837-011-0190-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-011-0190-3