Abstract

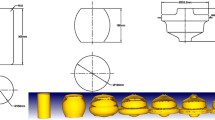

To research impeller parts flow behaviors in the die forging process, the finite element method is used to study the deformation flow behavior of different shapes in the blank forming process. The results show that the blade parts of the forgings were hard to fill, but with the section of the blade shifting down, the metal has a marked trend to flow toward this area of the die cavity. Compared with a cylindrical shape, the die cavity of the blade part can be filled more easily and the uniformity of metal flow will increase. Using a ladder shape to manufacture forgings of impellers can meet requirements for design and properties.

Similar content being viewed by others

References

B.P. Bewlay and M.F.X. Gigliotti, J. Mater. Process Technol., 135 (2003), pp. 324–329.

T.A. Dean, Mater. Des., 21 (2000), pp. 271–278.

H.S. Jeong et al., J. Mater. Process Technol., 162–163 (2005), pp. 504–511.

S.K. Choi et al., J. Mater. Process Technol., 172 (2006), pp. 88–95.

Y.L. Liu et al., J. Mater. Process Technol., 22 (2006), pp. 473–477.

Y.G. Zhou et al., Mater. Sci. Eng. A, 393 (2005), pp. 204–212.

J.W. Brooks et al., J. Mater. Process Technol., 80–81 (1998), pp. 149–155.

H. Yang et al., J. Mater. Process Technol., 151 (2004), pp. 63–69.

B.S. Kang et al., Int. J. Mach. Tool Manufac., 30 (1990), pp. 43–52.

D.B. Shan et al., J. Mater. Process Technol., 170 (2005), pp. 412–415.

P. Petrov, V. Perfilov, and S. Stebunov, J. Mater. Process Technol., 177 (2006), pp. 218–223.

J.J. Park and H.S. Hwang, J. Mater. Process Technol., 187–188 (2007), pp. 595–599

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, F., Lin, J.F. & Chu, G.N. Metal flow in the precision forging of aluminum alloys. JOM 61, 57–60 (2009). https://doi.org/10.1007/s11837-009-0122-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-009-0122-7