Abstract

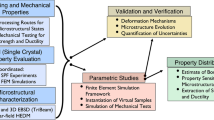

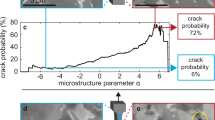

High-purity high residual resistivity ratio niobium is used to fabricate particle accelerator cavities for advanced superconducting accelerators. This material has an unstable texture that causes different r values in different inplane directions, which evolve with deformation, making prediction of forming characteristics difficult. Thus, an evolutionary yield function having coefficients that evolve with plastic deformation is introduced to account for gradients in microstructure and texture that evolve differently in different layers of the material. With such a model, failure modes and locations are predicted accurately in more complex deformation conditions.

Similar content being viewed by others

References

R. Hill, “A Theory of the Yielding and Plastic Flow of Anisotropic Metals,” Proceeding of the Royal Society of London. Series A, Mathematical and Physical Sciences, 193 (1948), p. 281.

R. Hill, “Theoretical Plasticity of Textured Aggregates,” Math. Proc. Camb. Phil. Soc., 85 (1979), p. 179.

R. Hill, “Constitutive Modeling of Anisotropic Plasticity in Sheet Metals,” J. Mech. Phys. Solids, 38 (1990), p. 405.

A.V. Hershey, “The Plasticity of an Isotropic Aggregate of Anisotropic Face Centered Cubic Crystals,” J. Appl. Mech., 30 (1954), p. 241.

W.F. Hosford, “A Generalized Isotropic Yield Criterion,” J. Appl. Mech., 39 (1972), p. 607.

J.L. Bassani, “Yield Characterization of Metals with Transversely Isotropic Plastic Properties,” Int. J. Mech. Sci., 19 (1977), p. 151.

M. Gotoh, “A Theory of Plastic Anisotropy Based on a Yield Function of Fourth Order (Plane Stress State),” Int. J. Mech. Sci., 19 (1977), p. 505.

R. Logan and W.F. Hosford, “On Yield Loci of Anisotropic Cubic Metals,” Int. J. Mech. Sci., 22 (1980), p. 419.

B. Budianski, “Anisotropic Plasticity of Plane-Isotropic Sheets,” Mechanics of Material Behavior, ed. G.J. Dvork and R.T. Shield (Amsterdam, The Netherlands: Elsevier, 1984), p 15.

F. Barlat and J. Lian, “Plastic Behavior and Stretch-ability of Sheet Metals Part I: Yield Function for Orthotropic Sheets under Plane Stress Conditions,” Int. J. Plasticity, 5 (1989), p. 51.

F. Barlat, D.J. Lege, and J.C. Brem, “A Six-component Yield Function for Anisotropic Metals,” Int. J. Plasticity, 7 (1991), p. 693.

F. Barlat, K. Chung, and O. Richmond, “Strain Rate Potential for Metals and Its Application to Minimum Plastic Work Path Calculations,” Int. J. Plasticity, 9 (1993), p. 1.

F. Barlat et al., “Yield Function Development for Aluminum Alloy Sheet,” J. Mech. Phys. Solids, 45 (1997), p. 1727.

F. Barlat et al., “Plane Stress Yield Function for Aluminum Alloy Sheets—Part 1: Theory,” Int. J. Plasticity, 19 (2004), p. 1297.

N. Abedrabbo and F. Pourboghrat, “Forming of Aluminum Alloys at Elevated Temperatures—Part 1,” Int. J. Plasticity, 22 (2006), p. 314.

A. Zamiri et al., “On Mechanical Properties of the Superconducting Niobium,” Materials Science and Engineering: A, 435–436 (2006), p. 658.

A. Zamiri, F. Pourboghrat, and F. Barlat, “Characterization and Development of an Evolutionary Yield Function for the Superconducting Niobium Sheet,” International Journal of Solids and Structures, 44 (2007), p. 8627.

ABAQUS manual, Version 6.3 (Providence, RI: Hibbit, Karlsson & Sorensen Inc., 2001).

J. et al., “Ferritic Steels—Optimization of Hot-Rolled Textures through Cold Rolling and Annealing,” Mater. Characterization, 47 (2001), p. 119.

A. Zamiri et al., “Investigation of Texture and its Effects on Physical and Mechanical Properties of High Purity RRR Niobium,” in preparation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zamiri, A., Jiang, H., Bieler, T.R. et al. Applying evolutionary yield function to predicting the deformation of microstructure-sensitive high-RRR niobium. JOM 60, 70–75 (2008). https://doi.org/10.1007/s11837-008-0094-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-008-0094-z