Abstract

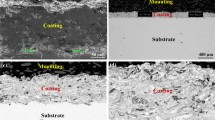

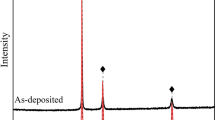

Nickel-based single-crystal superalloys with high concentrations of refractory elements are prone to generate a diffusion layer called a secondary reaction zone (SRZ) beneath their bond coating during long exposure to high temperatures. The SRZ causes a reduction of the load-bearing cross section and it is detrimental to the creep properties of thin-walled turbine airfoils. In this study, a new bond coat system, “EQ coating,” which is thermodynamically stable and suppresses SRZ has been proposed. Diffusion couples of coating materials and substrate alloys were made and heat treated at 1,100°C for 300 h and 1,000 h. Cyclic oxidation examinations were carried out at 1,100°C in air and the oxidation properties of EQ coating materials were discussed. High-velocity frame-sprayed EQ coatings designed for second-generation nickel-based superalloys were deposited on fourth-and fifth-generation nickel-based superalloys, and the stability of the microstructure at the interface and creep property of the coating system were investigated.

Similar content being viewed by others

References

J.X. Zhang et al., “Interfacial Dislocation Networks Strengthening a Fourth-Generation Single-Crystal TMS-138 Superalloy,” Metall. Mater. Trans. A, 33A (2002), pp. 3741–3746.

S. Walston et al., “Joint Development of a Fourth Generation Single Crystal Superalloy,” Superalloys 2004, ed. K.A. Green et al. (Warrendale, PA: TMS, 2004), pp. 15–24.

J.X. Zhang et al., “Strengthening by γ/γ′ Interfacial Dislocation Networks in TMS-162—Toward a Fifth-Generation Single-Crystal Superalloy,” Metall. Mater. Trans. A, 35A (2002), pp. 1911–1914.

W.S. Walston, J.C. Schaeffer, and W.H. Murphy, “A New Type of Microstructural Instability in Superalloys—SRZ,” Superalloys 1996, ed. R.D. Kissinger et al. (Warrendale, PA: TMS, 1996), pp. 9–18.

Y. Matsuoka et al., “The Formation of SRZ on a Fourth Generation Single Crystal Superalloy Applied with Aluminide Coating,” in Ref. 2, pp. 637–642.

E. Locci et al., “Successful Surface Treatments for Reducing Instabilities in Advanced Nickel-Base Superalloys for Turbine Blades,” NASA/TM-2004-212920 (March 2004).

O. Lavigne et al., “Relationships between Microstructural Instabilities and Mechanical Behavior in New Generation Nickel-Based Single Crystal Superalloys,” in Ref. 2, pp. 667–675.

T. Narita et al., “Alloy Coating, Method for Forming the Same, and Member for High Temperature Apparatuses,” U.S. patent 6,830,827 (2004).

T. Spitzberg et al., “Diffusion Barrier Layer,” U.S. patent 6,306,524 (2001).

R.G. Wing, “Method of Aluminizing a Superalloy,” U.S. patent 6,080,246 (2000).

H. Harada, A. Sato, and K. Kawagishi, Japanese patent pending, Tokugan 2005-092542 (2005).

A. Sato, H. Harada, and K. Kawagishi, “Development of New Bond Coat ‘EQ Coating’ System,” Metall. Mater. Trans. A, 37A (2006), pp. 789–791.

A. Sato, H. Harada, and K. Kawagishi, “Development of New Coatings for Advanced Ni-Base Superalloys,” J. Japan Inst. Metals, 70 (2006), pp. 192–195.

J. Ang et al., “The Oxidation Characteristics of the γ/gg′ Tie-Line Alloys of a Nickel-Based Superalloy,” Mater. Trans., 47 (2006), pp. 291–294.

K. Kawagishi, A. Sato, and H. Harada, “Development of Oxidation-Resistant β-phase EQ Coating System for Ni-Base Superalloys,” J. Japan Inst. Metals, 70 (2006), pp. 188–191.

K. Kawagishi et al., “Oxidation and Creep Properties of Ni-base Single Crystal Superalloy for β-phase EQ Coating System,” J. Japan Inst. Metals, 70 (2006), pp. 690–693.

K. Kawagishi et al., “Development of EQ Coating for New TBC system in Ni Based Superalloys,” Energy Materials, 1 (2006), pp. 213–217.

T. Hino et al., “Development of a New Single Crystal Superalloy for Industrial Gas Turbines,” Superalloys 2000, ed. T.M. Pollock et al. (Warrendale, PA: TMS, 2000), pp. 729–736.

Y. Koizumi et al., “Development of Next-Generation Ni-Base Single Crystal Superalloys,” in Ref. 2, pp. 35–43.

H. Harada et al., “Phase Calculation and Its Use in Alloy Design Program for Nickel-Base Superalloys,” Superalloys 1988, ed. S. Reichman et al. (Warrendale, PA: TMS, 1988), pp. 733–742.

A. Sato et al., “Effect of Aluminide Coating on Creep Properties of Ni-Base Single Crystal Superalloys,” J. Japan Inst. Metals, 71 (2007), pp. 320–325.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kawagishi, K., Sato, A. & Harada, H. A concept for the EQ coating system for nickel-based superalloys. JOM 60, 31–35 (2008). https://doi.org/10.1007/s11837-008-0086-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-008-0086-z