Abstract

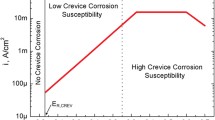

The U.S. Department of Energy (DOE) has indicated that it may use Alloy 22 as the waste package outer container material for the potential high-level waste repository at Yucca Mountain, Nevada. Additionally, a drip shield, made of titanium grade 7 and titanium grade 29, may extend the length of the emplacement drifts to enclose the top and sides of the emplaced waste package. Localized corrosion in the form of crevice corrosion could be one degradation process that may adversely affect the waste package performance. This paper will summarize the work conducted to evaluate the effects of environmental conditions relevant to the potential Yucca Mountain repository, metallurgical states (e.g., mill-annealed and welded plus solution annealed), and similar and dissimilar metal crevices on the crevice corrosion susceptibility of Alloy 22. This work also evaluates crevice corrosion propagation behavior resulting from contact with Alloy 22 or titanium grade 7.

Similar content being viewed by others

References

Risk Insights Baseline Report, NUREG-1762 (Washington, D.C.: NRC, July 2004).

G.A. Cragnolino et al., “Assessment of Performance Issues Related to Alternate Engineered Barrier System Materials and Design Options,” CNWRA 99-003 (San Antonio, TX: CNWRA, 1999).

S. Mohanty, T.J. McCartin, and D. Esh, corrdinators, “Total-system Performance Assessment (TPA), Version 4.0 Code: Module Descriptions and User’s Guide” (San Antonio, TX: CNWRA, 2002).

D.S. Dunn et al., “Modeling Corrosion Processes for Alloy 22 Waste Packages,” Scientific Basis for Nuclear Waste Management XXIX Symposium Proceedings Vol. 932, ed. P. Van Isheghem (Warrendale, PA: Materials Research Society, 2006), pp. 853–860.

D.S. Dunn et al., “Localized Corrosion Susceptibility of Alloy 22 in Chloride Solutions: Part 2—Effect of Fabrication Processes,” Corrosion, 62 (2006), pp. 3–12.

D.S. Dunn et al., “Passive and Localized Corrosion of Alloy 22—Modeling and Experiments,” CNWRA 2005-002 (San Antonio, TX: CNWRA, 2005).

D.S. Dunn et al., “Localized Corrosion Susceptibility of Alloy 22 in Chloride Solutions: Part 1—Mill-Annealed Condition,” Corrosion, 61 (2005), pp. 1078–1085.

X. He and D.S. Dunn, “Alloy 22 Localized Corrosion Propagation in Chloride-Containing Waters,” Corrosion, 63 (2007), pp. 145–158.

X. He and D.S. Dunn, “Alloy 22 Localized Corrosion Propagation in Chloride-Containing Waters,” CNWRA 2006-001 (San Antonio, TX: CNWRA, 2005).

“Metals Test Methods and Analytical Procedures,” ASTM G46-94 (2004): Standard Guide for Examination and Evaluation of Pitting Corrosion. Volume 3.02: Wear and Erosion—Metal Corrosion (West Conshohocken, PA: ASTM International, 2004), published on CD-ROM.

D.S. Dunn et al., “The Effects of Fabrication Processes on the Mechanical Properties of Waste Packages—Progress Report,” CNWRA 2004-03 (San Antonio, TX: CNWRA, 2004).

D.S. Dunn, D. Daruwalla, and Y.-M. Pan, “Effect of Fabrication Processes on Material Stability—Characterization and Corrosion,” CNWRA 2004-01 (San Antonio, TX: CNWRA, 2003).

R.L. Tapping, “Surface Studies of Austenitic Alloys Subjected to Crevice Corrosion in Sea Water,” Corrosion Science, 25 (1985), pp. 363–376.

Y.H. Kim and G.S. Frankel, “Effect of Noblel Element Alloying on Passivity and Passivity Breakdown on Ni,” J. Electrochemical Society, 154 (2007), pp. C36–C42.

J.R. Hayes et al., “Influence of Chromium and Molybdenum on the Corrosion of Nickel-Based Alloys,” Corrosion, 62 (2006), pp. 491–500.

A.C. Lloyd et al., “Effects of Temperature and Potential on the Passive Corrosion Properties of Alloys C22 and C276,” J. Electrochemical Society, 150 (2003), pp. B120–B130.

A.C. Lloyd et al., “Cr, Mo and W Alloying Additions in Ni and Their Effect on Passivity,” Electrochimica Acta, 49 (2004), pp. 3015–3027.

D.D. Macdonald, “The Point Defect Model for the Passive State,” J. Electrochemical Society, 139 (1992), pp. 3434–3448.

B.A. Kehler, G.O. Ilevbare, and J.R. Scully, “Crevice Corrosion Stabilization and Repassivation Behavior of Alloy 625 and Alloy 22,” Corrosion, 57 (2001), pp. 1042–1065.

N. Sridhar et al., “Stabilization and Repassivation of Localized Corrosion,” Proceedings of the CORROSION/2001 Research Topical Symposium, ed. G.S. Frankel and J.P. Scully (Houston, TX: NACE, 2001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

He, X., Mintz, T. Localized corrosion of alloy 22 in the potential Yucca Mountain repository environment. JOM 60, 44–51 (2008). https://doi.org/10.1007/s11837-008-0007-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-008-0007-1