Abstract

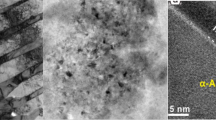

Severe plastic deformation, which refines grain size and introduces nanoscale features in metals and alloys, offers the prospect of enhancing metal properties beyond the levels otherwise attainalble. It allows stable deformation to larger strains than most conventional metal-forming methods, there by increasing the degree of strengthening possible. Before aprocess can be commercialized. it must be established that there are significant market drivers. Once those drivers are established, an array of factors must be considered that can impede or augment commercialization. This work will introduce four of these: competition from other materials, appropriability, maturity of design paradigm, and distribution of complementary assets.

Similar content being viewed by others

References

T.C. Lowe and Y.T. Zhu, Adv. Eng. Mat., 5 (5) (2003) pp. 373–378.

T.L. Brown et al, J. Mater. Res., 17 (110) (2002) pp. 2484–2488.

R. Valiev Nat. Mater., 3 (8) (2004), pp. 511–516.

K. Lu, Materials Science Forum, 475–479 (I) (2005) pp. 21–24.

Y.T. Zhu and J. Huang, Ultrafine Grained Materials II (Warrendale PA. TMS, 2002), pp. 331–340.

E. Ma, Met. Mater.-Int., 10 (6) (2004) pp. 527–531.

T. Lowe, Adv. Mater. Process., 160 (1) (2002), p. 63.

T.C. Lowe et al: NATO Science Partnership Sub-Series 3: High Technology 80 (2000) p. 347.

O.A. Kaibyshev, J. Mater. Process. Tech., 117 (3) (2001), pp. 300–306.

Y.T.T. Zhu and T.C. Lowe, Mat. Sci. Eng. A-Struct., 291 (1) (2000) p. 46–53.

R. Kaibyshev and I. Mazurina, Mat. Sci. Forum, 467/470 (2004) pp. 1251–1260.

A.L.M. Costa et al., Mat. Sci. Eng. A, 406 (1–2) (2005) p. 279–285.

E.F. Rauch, L. Dupuy, and J.J. Blandin, Key Eng. Mat., 230/232, (2002) pp. 239–242.

T.C. Lowe and R.Z. Valiev, JOM 56 (10) (2004), pp. 64–68.

X.Z. Liao, et al., J. Appl. Phys., 96 (1) (2004) pp. 636–640.

H.S. Kim, J. Mater. Process. Tech., 113 (1–3) (2001) pp. 617–621.

A.P. Zhilyaev et al., Acta Mater., 51 (3) (2003), pp 753–765.

D.V. Orlov, et al., Ultrafine Grained Materials III, (Warrendale, PA: TMS 2004) pp. 457–462.

G. Krallics and J.G. Lenard, J. Mater. Process. Tech., 152 (2) (2004) pp. 154–161.

S.H. Lee, T. Sakai, and D.H. Shin, Mater. Trans., 44 (7) (2003) pp. 1382–1385.

B. Cherukuri, T.S. Nedkova, and R. Srinivasan, Mater. Sci. Eng. A, 410–411 (2005) pp. 394–397.

T.C. Lowe, Mater. Sci. Forum ed. Z. Horita, 503–504, (2006) pp 355–362.

D.J. Teece, Res. Policy, 15 (6) (1986) pp. 186–203.

J. Dutkiewicz et al., Physica Status Solidi A, 202 (12) (2005), pp. 2309–2320.

M.L. Tushman and P. Anderson, Admin. Sci. Quart., (1986) pp 439–465.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lowe, T.C. Metals and alloys nanostructured by severe plastic deformation: Commercialization pathways. JOM 58, 28–32 (2006). https://doi.org/10.1007/s11837-006-0212-8

Issue Date:

DOI: https://doi.org/10.1007/s11837-006-0212-8