Abstract

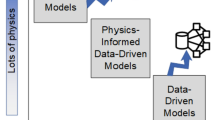

The effort that the materials science and metallurgical engineering communities have expended in developing high-fidelity process models can be exploited using model predictive control (MPC) technologies to provide very high process performance. This article presents a survey of the development of high-quality models and a discussion of how these could be used to improve process operation. A summary of the current state-of-the-art in process automation technologies and the common framework in which these technologies are deployed is presented, along with a tutorial on MPC within a materials-processing context.

Similar content being viewed by others

References

J.K. Brimacombe, “The Extractive Metallurgist in an Emerging World of Materials,” Metallurgical and Materials Transactions B, 20B (1989), pp. 291–313.

J.W. Evans, “Electricity in the Production of Metals: From Aluminum to Zinc,” Metallurgical and Materials Transactions B, 26B (1995), pp. 189–208.

R.I.L. Guthrie, “Fluid Flow in Metallurgy—Friend or Foe?” Howe Memorial Lecture, to be published in Metallurgical and Materials Transactions B.

J. Szekely, “The Mathematical Modelling Revolution in Extractive Metallurgy,” Metallurgical and Materials Transactions B, 19B (1988), pp. 525–540.

M. Cross, S. Johnson, and C. Ierotheou, “The Impact of Hardware on the Modelling and Analysis of Materials Processing Operations,” Materials Processing in the Computer Age, ed. V.R. Voller, M.S. Stachowicz, and B.G. Thomas (Warrendale, PA: TMS, 1991), pp. 35–44.

D. Guo and G.A. Irons, “Evaluation of Stirring in Electric Arc Furnaces,” ISM, 28 (10) (2001), pp. 43–47.

J.B. Wiskel and S.L. Cockcroft, “Heat Flow-Based Analysis of the Surface Crack Formation During the Start-Up of the Direct Chill Casting Process: Part II. Experimental Study of an AA5182 Rolling Ingot,” Metallurgical and Materials Transactions B, 27B (1996), pp. 129–137.

C. Bailey et al., “Modelling Interacting Phenomena During the Solidification of Metals in the Casting Process,” Fluid Flow Phenomena in Metal Processing, ed. S.T. Johansen and V.R. Voller (Warrendale, PA: TMS, 1999), pp. 3–10.

E.B. Damm et al., “Modeling Hot Bar Rolling to Predict Surface Quality,” ISM, 28 (10) (2001), pp. 29–35.

F. Siciliano and J.J. Jonas, “Mathematical Modeling of the Hot Strip Rolling of Microalloyed Nb, Multi-Alloyed Cr-Mo and Plain C-Mn Steels,” Metallurgical and Materials Transactions A, 31A (2000), pp. 511–530.

D.F.J. Staalman and A. Kusters, “On-line Slab Temperature Calculation and Control,” Manu. Sci. Eng., 4 (1996), pp. 307–314.

A.D. Acharya and S. Chattopadhyay, “Reheat Furnace Temperature Control and Performance at Essar Steel,” Iron Steel Eng. (November 1998), pp. 31–36.

P.O. Norberg, “Challenges in the Control of Reheating and Annealing Process,” Scand. J. Metall., 26 (1997), pp. 206–214.

J.F. Forbes, “Process Control: From PID to CIM,” Materials Processing in the Computer Age III, ed. Vaughan R. Voller and Hani Henein, (Warrendale, PA: TMS, 2000), pp. 15–25.

B. Lally, L. Biegler, and H. Henein, “A Model for Sequencing a Continuous Casting Operation to Minimize Costs,” ISS Transactions, 9 (1988), pp. 123–130.

B. Lally, L. Biegler, and H. Henein, “Optimization and Continuous Casting—Part II: Solution to Industrial Casters,” Metallurgical Transactions B, 22B (1991), pp. 649–659.

C.R. Cutler and B.L. Ramaker, “Dynamic Matrix Control: A Computer Control Algorithm” (Paper presented at the 86th National AIChE Meeting, Houston, TX, April 1979), 51b.

S.J. Qin and T.A. Badgwell, “An Overview of Industrial Model Predictive Control Technology,” Proceedings of the 5th International Conference on Chemical Process Control, ed. Jeffrey C. Kantor, Carlos E. Garcia, and Brice Carnahan, AIChE Symposium Series 316, 93 (1996), pp. 232–256.

C.E. Garcia, D.M. Prett, and M. Morari, “Model Predictive Control: Theory and Practice,” Automatica, 25 (1989) pp. 335–348.

D.Q. Mayne, “Nonlinear Model Predictive Control: An Assessment,” Proceedings of the 5th International Conference on Chemical Process Control, ed. Jeffrey C. Kantor, Carlos E. Garcia, and Brice Carnahan, AIChE Symposium Series 316, 93 (1996), pp. 217–231.

A. Bemporad et al., “Model Predictive Control—Ideas for the Next Generation,” Presented at the European Control Conference, Karlsruhe, Germany, 1999.

B.A. Ogunnaike and W.H. Ray, Process Dynamics, Modeling, and Control (New York: Oxford, 1995).

J.M. Maciejowski, Predictive Control with Constraints (Harlow, U.K.: Prentice Hall, 2002).

H. Shang, J.F. Forbes, and M. Guay, “Characteristics-based Model Predictive Control of Distributed Parameter Systems,” Paper presented at the American Control Conference, (Anchorage Alaska, 2002).

F.H. Clarke, “Nonlinear Feedback Control and Nonsmooth Analysis,” (2001).

Author information

Authors and Affiliations

Additional information

For more information, contact J. Fraser Forbes, University of Alberta, Department of Chemical and Materials Engineering, Edmonton, AB, Canada T6G 2G6; (780) 492-0873; fax (780) 492-2881; e-mail fraser.forbes@ualberta.ca.

Rights and permissions

About this article

Cite this article

Shang, H., Wiskel, J.B., Forbes, J.F. et al. Exploiting model fidelity to control metals processing. JOM 55, 41–45 (2003). https://doi.org/10.1007/s11837-003-0159-y

Issue Date:

DOI: https://doi.org/10.1007/s11837-003-0159-y