Abstract

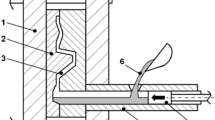

Titanium precision castings have not kept pace with technical design requirements for demanding applications, such as the aerospace industry; advances in increased size capability have been offset by a lack of advances in metallurgical integrity and dimensional tolerances. Hence, there is a strong need for improvement in the casting process. Taramm has developed a process that combines cold-crucible induction melting and centrifugal pouring to produce viable castings.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

For more information, contact John Bannister, CJ Associates, 20125 S. Ford Center, Oregon City, Oregon 97045; (503) 631-3348; fax (503) 631-7508; e-mail blsitw@aol.com.

Rights and permissions

About this article

Cite this article

Broihanne, G., Bannister, J. Using cold-crucible melting for titanium precision castings. JOM 52, 21–23 (2000). https://doi.org/10.1007/s11837-000-0026-z

Issue Date:

DOI: https://doi.org/10.1007/s11837-000-0026-z