Abstract

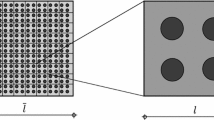

The continuous increase of computational capacity has encouraged the extensive use of multiscale techniques to simulate the material behaviour on several fields of knowledge. In solid mechanics, the multiscale approaches which consider the macro-scale deformation gradient to obtain the homogenized material behaviour from the micro-scale are called first-order computational homogenization. Following this idea, the second-order FE2 methods incorporate high-order gradients to improve the simulation accuracy. However, to capture the full advantages of these high-order framework the classical boundary value problem (BVP) at the macro-scale must be upgraded to high-order level, which complicates their numerical solution. With the purpose of obtaining the best of both methods i.e. first-order and second-order, in this work an enhanced-first-order computational homogenization is presented. The proposed approach preserves a classical BVP at the macro-scale level but taking into account the high-order gradient of the macro-scale in the micro-scale solution. The developed numerical examples show how the proposed method obtains the expected stress distribution at the micro-scale for states of structural bending loads. Nevertheless, the macro-scale results achieved are the same than the ones obtained with a first-order framework because both approaches share the same macro-scale BVP.

Similar content being viewed by others

References

Amstutz S, Giusti SM, Novotny AA, De Souza Neto EA (2010) Topological derivative for multi-scale linear elasticity models applied to the synthesis of microstructures. Int J Numer Methods Eng 84(6):733–756. doi:10.1002/nme.2922 (arXiv:1010.1724)

Barbero EJ (2010) Introduction to composite materials design, 2nd edn. CRC Press, Boca Raton

Bazant ZP (2010) Can multiscale-multiphysics methods predict softening damage and structural failure? Int J Multiscale Comput Eng 8(1):61–67. doi:10.1615/IntJMultCompEng.v8.i1.50

Belytschko T, Loehnert S, Song JH (2008) Multiscale aggregating discontinuities: a method for circumventing loss of material stability. Int J Numer Methods Eng 73(6):869–894. doi:10.1002/nme.2156 (arXiv:1010.1724)

Belytschko T, Song JH (2010) Coarse-graining of multiscale crack propagation. Int J Numer Methods Eng 81(5):537–563. doi:10.1002/nme.2694 (arXiv:1010.1724)

Bendsoe MP, Kikuchi N (1988) Generating optimal topologies in structural design using a homogenization method. Comput Methods Appl Mech Eng 71(2):197–224. doi:10.1016/0045-7825(88)90086-2

Bensoussan A, Lions J, Papanicolaou G (1978) Asymptotic analysis for periodic structures. North-Holland, Amsterdam

Blanco PJ, Giusti SM (2014) Thermomechanical multiscale constitutive modeling: accounting for microstructural thermal effects. J Elast 115(1):27–46. doi:10.1007/s10659-013-9445-2

Broughton J, Abraham F, Bernstein N, Kaxiras E (1999) Concurrent coupling of length scales: methodology and application. Phys Rev B 60(4):2391–2403. doi:10.1103/PhysRevB.60.2391

Budiansky B (1965) On the elastic moduli of some heterogeneous materials. J Mech Phys Solids 13(4):223–227. doi:10.1016/0022-5096(65)90011-6

Chatzigeorgiou G, Javili A, Steinmann P (2014) Unified magnetomechanical homogenization framework with application to magnetorheological elastomers. Math Mech Solids 19(2):193–211. doi:10.1177/1081286512458109

Chung PW, Tamma KK, Namburu RR (2001) Asymptotic expansion homogenization for heterogeneous media: computational issues and applications. Compos Part A Appl Sci Manuf 32(9):1291–1301. doi:10.1016/S1359-835X(01)00100-2

Coenen E, Kouznetsova V, Geers M (2012a) Novel boundary conditions for strain localization analyses in microstructural volume elements. Int J Numer Methods Eng 90(1):1–21. doi:10.1002/nme.3298

Coenen EWC, Kouznetsova VG, Geers MGD (2012b) Multi-scale continuous-discontinuous framework for computational- homogenization-localization. J Mech Phys Solids 60(8):1486–1507. doi:10.1016/j.jmps.2012.04.002

de Souza Neto EA, Feijóo RA (2006) Variational foundations of multi-scale constitutive models of solid: small and large strain kinematical formulation. Techinical report, LNCC research and development report, No 16. National laboratory for scientific computing, Petrópolis

de Souza Neto E, Feijóo R (2008) On the equivalence between spatial and material volume averaging of stress in large strain multi-scale solid constitutive models. Mech Mater 40(10):803–811. doi:10.1016/j.mechmat.2008.04.006

Dong JW, Feng MI (2010) Asymptotic expansion homogenization for simulating progressive damage of 3D braided composites. Compos Struct 92(4):873–882. doi:10.1016/j.compstruct.2009.09.026

Drugan WJ, Willis JR (1996) A micromechanics-based nonlocal constitutive equation and estimates of representative volume element size for elastic composites. J Mech Phys Solids 44(4):497–524. doi:10.1016/0022-5096(96)00007-5

Elmekati A, Shamy UE (2010) A practical co-simulation approach for multiscale analysis of geotechnical systems. Comput Geotech 37(4):494–503. doi:10.1016/j.compgeo.2010.02.002

Eshelby JD (1957) The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc R Soc A Math Phys Eng Sci 241:376–396. doi:10.1098/rspa.1957.0133

Ferrer A, Oliver J, Cante JC, Lloberas-Valls O (2016) Vademecum-based approach to multi-scale topological material design. Adv Model Simul Eng Sci 3(1):1–22. doi:10.1186/s40323-016-0078-4

Feyel F (1998) Application du calcul parallèle aux modèlles à grand nombre de variables inernes. Ph.D. thesis, Ecole des Mines de Paris

Feyel F (1999) Multiscale FE2 elastoviscoplastic analysis of composite structures. Comput Mater Sci 16(1–4):344–354. doi:10.1016/S0927-0256(99)00077-4

Feyel F (2003) A multilevel finite element method (FE2) to describe the response of highly non-linear structures using generalized continua. Comput Methods Appl Mech Eng 192(28–30):3233–3244. doi:10.1016/S0045-7825(03)00348-7

Feyel F, Chaboche JL (2000) FE2 multiscale approach for modelling the elastoviscoplastic behaviour of long fibre SiC/Ti composite materials. Comput Methods Appl Mech Eng 183(3–4):309–330. doi:10.1016/S0045-7825(99)00224-8

Fish J, Shek K, Pandheeradi M, Shephard MS (1997) Computational plasticity for composite structures based on mathematical homogenization: theory and practice. Comput Methods Appl Mech Eng 148(1–2):53–73. doi:10.1016/S0045-7825(97)00030-3

Fish J, Yu Q, Shek K (1999) Computational damage mechanics for composite materials based on mathematical homogenization. Int J Numer Methods Eng 45(11):1657–1679. doi:10.1002/(SICI)1097-0207(19990820)45:11<1657::AID-NME648>3.0.CO;2-H

Fish J, Yuan Z (2005) Multiscale enrichment based on partition of unity. Int J Numer Methods Eng 62(10):1341–1359. doi:10.1002/nme.1230

Geers MGD, Coenen EWC, Kouznetsova VG (2007) Multi-scale computational homogenization of structured thin sheets. Model Simul Mater Sci Eng 15(4):S393–S404. doi:10.1088/0965-0393/15/4/S06

Geers MGD, Kouznetsova VG, Brekelmans WAM (2010) Multi-scale computational homogenization: trends and challenges. J Comput Appl Math 234(7):2175–2182. doi:10.1016/j.cam.2009.08.077

Ghosh S, Lee K, Raghavan P (2001) A multi-level computational model for multi-scale damage analysis in composite and porous materials. Int J Solids Struct 38(14):2335–2385. doi:10.1016/S0020-7683(00)00167-0

Ghosh S, Bai J, Raghavan P (2007) Concurrent multi-level model for damage evolution in microstructurally debonding composites. Mech Mater 39(3):241–266. doi:10.1016/j.mechmat.2006.05.004

Gitman I, Askes H, Sluys L (2007) Representative volume: existence and size determination. Eng Fract Mech 74(16):2518–2534. doi:10.1016/j.engfracmech.2006.12.021

Giusti S, Blanco P, de Souza Netoo E, Feijóo R (2009) An assessment of the Gurson yield criterion by a computational multi-scale approach. Eng Comput 26(3):281–301. doi:10.1108/02644400910943626

González C, Segurado J, LLorca J (2004) Numerical simulation of elasto-plastic deformation of composites: evolution of stress microfields and implications for homogenization models. J Mech Phys Solids 52(7):1573–1593. doi:10.1016/j.jmps.2004.01.002

Guedes J, Kikuchi N (1990) Preprocessing and postprocessing for materials based on the homogenization method with adaptive finite element methods. Comput Methods Appl Mech Eng 83(2):143–198. doi:10.1016/0045-7825(90)90148-F

Gurson A (1977) Continuum theory of ductile rupture by void nucleation and growth: part I–yield criteria and flow rules for porous ductile media. J Eng Mater Technol 99(1):2–15. doi:10.1115/1.3443401

Hashin Z (1962) The elastic moduli of heterogeneous materials. J Appl Mech 29(1):143–150. doi:10.1115/1.3636446

Hashin Z, Shtrikman S (1962) On some variational principles in anisotropic and nonhomogeneous elasticity. J Mech Phys Solids 10(4):335–342. doi:10.1016/0022-5096(62)90004-2

Hashin Z, Shtrikman S (1963) A variational approach to the theory of the elastic behaviour of multiphase materials. J Mech Phys Solids 11(2):127–140. doi:10.1016/0022-5096(63)90060-7

Hernández J, Oliver J, Huespe A, Caicedo M, Cante J (2014) High-performance model reduction techniques in computational multiscale homogenization. Comput Methods Appl Mech Eng 276:149–189. doi:10.1016/j.cma.2014.03.011

Hill R (1963) Elastic properties of reinforced solids: some theoretical principles. J Mech Phys Solids 11(5):357–372. doi:10.1016/0022-5096(63)90036-X

Hill R (1965a) A self-consistent mechanics of composite materials. J Mech Phys Solids 13(4):213–222. doi:10.1016/0022-5096(65)90010-4

Hill R (1965b) Continuum micro-mechanics of elastoplastic polycrystals. J Mech Phys Solids 13(2):89–101. doi:10.1016/0022-5096(65)90023-2

Hill R (1972) On constitutive macro-variables for heterogeneous solids at finite strain. Proc R Soc Lond A 326(1565):131–147. doi:10.1098/rspa.1972.0001

Hill R (1984) On macroscopic effects of heterogeneity in elastoplastic media at finite strain. Math Proc Camb Philos Soc 95(03):481. doi:10.1017/S0305004100061818

Hund A, Ramm E (2007) Locality constraints within multiscale model for non-linear material behaviour. Int J Numer Methods Eng 70(13):1613–1632. doi:10.1002/nme.1953

Ilic S, Hackl K (2009) Application of the multiscale FEM to the modeling of nonlinear multiphase materials. J Theor Appl Mech 47(3):537–551

Javili A, Chatzigeorgiou G, Steinmann P (2013) Computational homogenization in magneto-mechanics. Int J Solids Struct 50(25–26):4197–4216. doi:10.1016/j.ijsolstr.2013.08.024

Kaczmarczyk L, Pearce CJ, Bićanić N (2008) Scale transition and enforcement of RVE boundary conditions in second-order computational homogenization. Int J Numer Methods Eng 74(3):506–522. doi:10.1002/nme.2188

Kalamkarov AL, Andrianov IV, Danishevs’kyy VV (2009) Asymptotic homogenization of composite materials and structures. Appl Mech Rev 62(3):030,802, doi:10.1115/1.3090830, arXiv:77950863481

Kanit T, N’Guyen F, Forest S, Jeulin D, Reed M, Singleton S (2006) Apparent and effective physical properties of heterogeneous materials: representativity of samples of two materials from food industry. Comput Methods Appl Mech Eng 195(33–36):3960–3982. doi:10.1016/j.cma.2005.07.022

Kanit T, Forest S, Galliet I, Mounoury V, Jeulin D (2003) Determination of the size of the representative volume element for random composites: statistical and numerical approach. Int J Solids Struct 40(13–14):3647–3679. doi:10.1016/S0020-7683(03)00143-4

Kanouté P, Boso DP, Chaboche JL, Schrefler BA (2009) Multiscale methods for composites: a review. Arch Comput Methods Eng 16(1):31–75. doi:10.1007/s11831-008-9028-8

Kato J, Yachi D, Terada K, Kyoya T (2014) Topology optimization of micro-structure for composites applying a decoupling multi-scale analysis. Struct Multidiscip Optim 49(4):595–608. doi:10.1007/s00158-013-0994-6

Keip MA, Steinmann P, Schröder J (2014) Two-scale computational homogenization of electro-elasticity at finite strains. Comput Methods Appl Mech Eng 278:62–79. doi:10.1016/j.cma.2014.04.020

Klinge S, Hackl K (2012) Application of the multiscale fem to the modeling of nonlinear composites with a random microstructure. Int J Multiscale Comput Eng 10(3):213–227. doi:10.1615/IntJMultCompEng.002059

Kouznetsova VG (2002) Computational homogenization for the multi-scale analysis of multi-phase materials. Ph.D. thesis, Eindhoven University of Technology, Eindhoven, The Netherlands

Kouznetsova V, Brekelmans WAM, Baaijens FPT (2001) Approach to micro-macro modeling of heterogeneous materials. Comput Mech 27(1):37–48. doi:10.1007/s004660000212

Kouznetsova V, Geers MGD, Brekelmans WAM (2002) Multi-scale constitutive modelling of heterogeneous materials with a gradient-enhanced computational homogenization scheme. Int J Numer Methods Eng 54(8):1235–1260. doi:10.1002/nme.541

Kouznetsova VG, Geers MGD, Brekelmans WAM (2004) Multi-scale second-order computational homogenization of multi-phase materials: a nested finite element solution strategy. Comput Methods Appl Mech Eng 193(48–51):5525–5550. doi:10.1016/j.cma.2003.12.073

Ladevèze P, Loiseau O, Dureisseix D (2001) A micro-macro and parallel computational strategy for highly heterogeneous structures. Int J Numer Methods Eng 52(12):121–138. doi:10.1002/nme.274

Lahellec N, Suquet P (2007) On the effective behavior of nonlinear inelastic composites: I. Incremental variational principles. J Mech Phys Solids 55(9):1932–1963. doi:10.1016/j.jmps.2007.02.003

Lamari H, Ammar A, Cartraud P, Legrain G, Chinesta F, Jacquemin F (2010) Routes for efficient computational homogenization of nonlinear materials using the proper generalized decompositions. Arch Comput Methods Eng 17(4):373–391. doi:10.1007/s11831-010-9051-4

Larsson R, Diebels S (2007) A second-order homogenization procedure for multi-scale analysis based on micropolar kinematics. Int J Numer Methods Eng 69(12):2485–2512. doi:10.1002/nme.1854. arXiv:1010.1724

Larsson R, Zhang Y (2007) Homogenization of microsystem interconnects based on micropolar theory and discontinuous kinematics. J Mech Phys Solids 55(4):819–841. doi:10.1016/j.jmps.2006.09.010

Lloberas-Valls O, Rixen D, Simone A, Sluys L (2012) On micro-to-macro connections in domain decomposition multiscale methods. Comput Methods Appl Mech Eng 225:177–196. doi:10.1016/j.cma.2012.03.022

Mandel J (1971) Plasticité Classique Et Viscoplasticité. International Centre for Mechanical Sciences. Courses and lectures, Springer, Udine, https://books.google.es/books?id=zvHaoAEACAAJ

Matsui K, Terada K, Yuge K (2004) Two-scale finite element analysis of heterogeneous solids with periodic microstructures. Comput Struct 82(7–8):593–606. doi:10.1016/j.compstruc.2004.01.004

McDowell DL (2010) A perspective on trends in multiscale plasticity. Int J Plast 26(9):1280–1309. doi:10.1016/j.ijplas.2010.02.008

Melro A, Camanho P, Pinho S (2012) Influence of geometrical parameters on the elastic response of unidirectional composite materials. Compos Struct 94(11):3223–3231. doi:10.1016/j.compstruct.2012.05.004

Michel J, Moulinec H, Suquet P (1999) Effective properties of composite materials with periodic microstructure: a computational approach. Comput Methods Appl Mech Eng 172(1–4):109–143. doi:10.1016/S0045-7825(98)00227-8

Miehe C, Schröder J, Schotte J (1999) Computational homogenization analysis in finite plasticity Simulation of texture development in polycrystalline materials. Comput Methods Appl Mech Eng 171(3–4):387–418. doi:10.1016/S0045-7825(98)00218-7

Miehe C (2002) Strain-driven homogenization of inelastic microstructures and composites based on an incremental variational formulation. Int J Numer Methods Eng 55(11):1285–1322. doi:10.1002/nme.515

Miehe C, Schröder J, Bayreuther C (2002) On the homogenization analysis of composite materials based on discretized fluctuations on the micro-structure. Acta Mech 155(1–2):1–16. doi:10.1007/BF01170836

Miehe C, Dettmar J, Zäh D (2010) Homogenization and two-scale simulations of granular materials for different microstructural constraints. Int J Numer Methods Eng 83(8–9):1206–1236. doi:10.1002/nme.2875

Miehe C, Vallicotti D, Teichtmeister S (2016) Homogenization and multiscale stability analysis in finite magneto-electro-elasticity. Application to soft matter EE, ME and MEE composites. Comput Methods Appl Mech Eng 300:294–346. doi:10.1016/j.cma.2015.10.013

Miehe C, Koch A (2002) Computational micro-to-macro transitions of discretized microstructures undergoing small strains. Arch Appl Mech 72(4–5):300–317. doi:10.1007/s00419-002-0212-2

Monteiro E, Yvonnet J, He Q (2008) Computational homogenization for nonlinear conduction in heterogeneous materials using model reduction. Comput Mater Sci 42(4):704–712. doi:10.1016/j.commatsci.2007.11.001

Mosby M, Matouš K (2015) Hierarchically parallel coupled finite strain multiscale solver for modeling heterogeneous layers. Int J Numer Methods Eng 102(3–4):748–765. doi:10.1002/nme.4755

Nemat-Nasser S (1999a) Averaging theorems in finite deformation plasticity. Mech Mater 31(8):493–523. doi:10.1016/S0167-6636(98)00073-8

Nemat-Nasser S (1999b) Averaging theorems in finite deformation plasticity. Mech Mater 31(8):493–523. doi:10.1016/S0167-6636(98)00073-8

Nguyen VPHU, Stroeven M, Sluys LJ (2011) Multiscale continuous and discontinuous modeling of heterogeneous materials : a review on recent developments. J Multiscale Model 3(4):1–42. doi:10.1142/S1756973711000509

Oden JT, Vemaganti K, Moës N (1999) Hierarchical modeling of heterogeneous solids. Comput Methods Appl Mech Eng 172(1):3–25. doi:10.1016/S0045-7825(98)00224-2

Oliver J (1996) Modelling strong discontinuities in solid mechanics via strain softening constitutive equations. Part 1: fundamentals. Int J Numer Methods Eng 39(21):3575–3600. doi:10.1002/(SICI)1097-0207(19961115)39:21<3575::AID-NME65>3.0.CO;2-E

Oliver J, Caicedo M, Roubin E, Huespe AE, Hernández JA (2015) Continuum approach to computational multiscale modeling of propagating fracture. Comput Methods Appl Mech Eng 294:384–427. doi:10.1016/j.cma.2015.05.012

Oliver J, Huespe AE (2004a) Continuum approach to material failure in strong discontinuity settings. Comput Methods Appl Mech Eng 193(30–32):3195–3220. doi:10.1016/j.cma.2003.07.013

Oliver J, Huespe AE (2004b) Theoretical and computational issues in modelling material failure in strong discontinuity scenarios. Comput Methods Appl Mech Eng 193(27–29):2987–3014. doi:10.1016/j.cma.2003.08.007

Oller S, Miquel Canet J, Zalamea F (2005) Composite material behavior using a homogenization double scale method. J Eng Mech 131(1):65–79. doi:10.1061/(ASCE)0733-9399(2005)131:1(65)

Ostoja-Starzewski M (2002) Microstructural randomness versus representative volume element in thermomechanics. J Appl Mech 69(1):25–35. doi:10.1115/1.1410366

Ostoja-Starzewski M (2006) Material spatial randomness: from statistical to representative volume element. Probab Eng Mech 21(2):112–132. doi:10.1016/j.probengmech.2005.07.007

Otero F (2016) Multiscale numerical modelling of microstructured reinforced composites. Ph.D. thesis, Universitat Politècnica de Catalunya (BarcelonaTECH). doi:10.13140/RG.2.1.5155.5600

Otero F, Martinez X, Oller S, Salomón O (2015) An efficient multi-scale method for non-linear analysis of composite structures. Compos Struct 131:707–719. doi:10.1016/j.compstruct.2015.06.006

Otero F, Oller S, Martinez X, Salomón O (2015b) Numerical homogenization for composite materials analysis. Comparison with other micro mechanical formulations. Compos Struct 122:405–416. doi:10.1016/j.compstruct.2014.11.041

Özdemir I, Brekelmans WAM, Geers MGD (2008) FE2 computational homogenization for the thermo-mechanical analysis of heterogeneous solids. Comput Methods Appl Mech Eng 198(3–4):602–613. doi:10.1016/j.cma.2008.09.008

Pérez MA, Martínez X, Oller S, Gil L, Rastellini F, Flores F (2013) Impact damage prediction in carbon fiber-reinforced laminated composite using the matrix-reinforced mixing theory. Compos Struct 104:239–248. doi:10.1016/j.compstruct.2013.04.021

Perić D, de Souza Neto EA, Feijóo RA, Partovi M, Molina AJC (2011) On micro-to-macro transitions for multi-scale analysis of non-linear heterogeneous materials: unified variational basis and finite element implementation. Int J Numer Methods Eng 87(1–5):149–170. doi:10.1002/nme.3014

Pinho-da Cruz J, Oliveira J, Teixeira-Dias F (2009) Asymptotic homogenisation in linear elasticity. Part I: mathematical formulation and finite element modelling. Comput Mater Sci 45(4):1073–1080. doi:10.1016/j.commatsci.2009.02.025

PLCd research group (1991-to present) PLCd: Non-linear thermo-mechanic finite element code for research-oriented applications. Free access code developed at CIMNE. http://www.cimne.com/PLCd

Reis FJP, Andrade Pires FM (2013) An adaptive sub-incremental strategy for the solution of homogenization-based multi-scale problems. Comput Methods Appl Mech Eng 257:164–182. doi:10.1016/j.cma.2013.01.003

Renard J, Marmonier MF (1987) Etude de l’initiation de l’endommagement dans la matrice d’un matériau composite par une méthode d’homogénéisation. Aerosp Sci Technol 6:37–51

Sanchez-Palencia E (1980) Non-homogeneous media and vibration theory. In: Lecture Notes in Physics, Lecture Notes in Physics, vol 127, Springer, Berlin, Heidelberg. doi:10.1007/3-540-10000-8

Sanchez-Palencia E (1983) Homogenization method for the study of composite media. In: Verhulst F (ed) Asymptotic analysis II, Lecture Notes in mathematics, vol 985, Springer, Berlin, Heidelberg, pp 192–214. doi:10.1007/BFb0062368

Schröder J (2009) Derivation of the localization and homogenization conditions for electro-mechanically coupled problems. Comput Mater Sci 46(3):595–599. doi:10.1016/j.commatsci.2009.03.035

Schröder J (2014) A numerical two-scale homogenization scheme: the FE2-method. In: Plasticity and Beyond: Microstructures, Crystal-Plasticity and Phase Transitions, vol 550, pp 1–64. doi:10.1007/978-3-7091-1625-8_1

Schury F, Stingl M, Wein F (2012) Efficient two-scale optimization of manufacturable graded structures. SIAM J Sci Comput 34(6):B711–B733. doi:10.1137/110850335

Segurado J, Llorca J (2002) A numerical approximation to the elastic properties of sphere-reinforced composites. J Mech Phys Solids 50(10):2107–2121. doi:10.1016/S0022-5096(02)00021-2

Smit R, Brekelmans W, Meijer H (1998) Prediction of the mechanical behavior of nonlinear heterogeneous systems by multi-level finite element modeling. Comput Methods Appl Mech Eng 155(1–2):181–192. doi:10.1016/S0045-7825(97)00139-4

Smit R, Brekelmans W, Meijer H (1999) Prediction of the large-strain mechanical response of heterogeneous polymer systems: local and global deformation behaviour of a representative volume element of voided polycarbonate. J Mech Phys Solids 47(2):201–221. doi:10.1016/S0022-5096(98)00089-1

Somer DD, de Souza Neto EA, Dettmer WG, Perić D (2009) A sub-stepping scheme for multi-scale analysis of solids. Comput Methods Appl Mech Eng 198(9–12):1006–1016. doi:10.1016/j.cma.2008.11.013

Song JH, Belytschko T (2009) Multiscale aggregating discontinuities method for micro-macro failure of composites. Compos Part B Eng 40(6):417–426. doi:10.1016/j.compositesb.2009.01.007

Sunyk R, Steinmann P (2003) On higher gradients in continuum-atomistic modelling. Int J Solids Struct 40(24):6877–6896. doi:10.1016/j.ijsolstr.2003.07.001

Suquet PM (1985) Local and global aspects in the mathematical theory of plasticity. In: Sawczuk A, Bianchi G (eds) Plasticity today—modeling methods and applications. Elsevier, London, pp 279–310

Swan CC (1994) Techniques for stress- and strain-controlled homogenization of inelastic periodic composites. Comput Methods Appl Mech Eng 117(3–4):249–267. doi:10.1016/0045-7825(94)90117-1

Takano N, Ohnishi Y, Zako M, Nishiyabu K (2000) The formulation of homogenization method applied to large deformation problem for composite materials. Int J Solids 37(44):6517–6535. doi:10.1016/S0020-7683(99)00284-X

Temizer I (2012) On the asymptotic expansion treatment of two-scale finite thermoelasticity. Int J Eng Sci 53:74–84. doi:10.1016/j.ijengsci.2012.01.003

Temizer I, Wriggers P (2011a) An adaptive multiscale resolution strategy for the finite deformation analysis of microheterogeneous structures. Comput Methods Appl Mech Eng 200(37):2639–2661. doi:10.1016/j.cma.2010.06.013

Temizer I, Wriggers P (2011b) Homogenization in finite thermoelasticity. J Mech Phys Solids 59(2):344–372. doi:10.1016/j.jmps.2010.10.004

Temizer I, Zohdi TI (2007) A numerical method for homogenization in non-linear elasticity. Comput Mech 40(2):281–298. doi:10.1007/s00466-006-0097-y

Terada K, Hori M, Kyoya T, Kikuchi N (2000) Simulation of the multi-scale convergence in computational homogenization approaches. Int J Solids Struct 37(16):2285–2311. doi:10.1016/S0020-7683(98)00341-2

Terada K, Saiki I, Matsui K, Yamakawa Y (2003) Two-scale kinematics and linearization for simultaneous two-scale analysis of periodic heterogeneous solids at finite strain. Comput Methods Appl Mech Eng 192(31–32):3531–3563. doi:10.1016/S0045-7825(03)00365-7

Terada K, Kurumatani M, Ushida T, Kikuchi N (2010) A method of two-scale thermo-mechanical analysis for porous solids with micro-scale heat transfer. Comput Mech 46(2):269–285. doi:10.1007/s00466-009-0400-9

Terada K, Kikuchi N (2001) A class of general algorithms for multi-scale analyses of heterogeneous media. Comput Methods Appl Mech Eng 190(40–41):5427–5464. doi:10.1016/S0045-7825(01)00179-7

Unger JF (2013) An FE2-X1 approach for multiscale localization phenomena. J Mech Phys Solids 61(4):928–948. doi:10.1016/j.jmps.2012.12.010

van der Sluis O, Schreurs PJG, Meijer HEH (1999) Effective properties of a viscoplastic constitutive model obtained by homogenization. Mech Mater 31(11):743–759. doi:10.1016/S0167-6636(99)00028-9

van der Sluis O, Schreurs P, Brekelmans W, Meijer H (2000) Overall behaviour of heterogeneous elastoviscoplastic materials: effect of microstructural modelling. Mech Mater 32(8):449–462. doi:10.1016/S0167-6636(00)00019-3

Wellmann C, Wriggers P (2012) A two-scale model of granular materials. Comput Methods Appl Mech Eng 205:46–58. doi:10.1016/j.cma.2010.12.023

Xia L, Breitkopf P (2014) Concurrent topology optimization design of material and structure within FE2 nonlinear multiscale analysis framework. Comput Methods Appl Mech Eng 278:524–542. doi:10.1016/j.cma.2014.05.022

Yvonnet J, He QC (2007) The reduced model multiscale method (R3M) for the non-linear homogenization of hyperelastic media at finite strains. J Comput Phys 223(1):341–368. doi:10.1016/j.jcp.2006.09.019

Acknowledgements

This work has been supported by European Research Council through of Advanced Grant: ERC-2012-AdG 320815 COMP-DES-MAT “Advanced tools for computational design of engineering materials”, by the Spanish Ministerio de Economia y Competividad through the project: MAT2014-60647-R “Multi-scale and multi-objective optimization of composite laminate structures (OMMC)”, by European Union 7th Framework Programme under an IRSES Marie Curie Action: PIRSES-GA-2013-612607 TCAiNMaND, by the collaboration effort between the EU-H2020 (Agreement No 690638) and the People’s Republic of China (Agreement No [2016]92) “ECOCOMPASS”, and by Universitat Politècnica de Catalunya (UPC). All this support is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Human and Animals Rights Statement

This work does not contain any studies with human participants or animals performed by any of the authors.

Appendix: Microscopic Kinematic Relationships for the EFOCH

Appendix: Microscopic Kinematic Relationships for the EFOCH

In the following are described the kinematic relationships defined between master and slaves nodes of the RVE, required for the implementation of the EFOCH in a FEM software.

In the Fig. 17, it is possible identify easily master nodes (named with a letter) and slave nodes (named with a letter and number). This is when a structured FE mesh on the boundary of the RVE is used. In the vertices nodes, also it is possible to identify a master node (“1”) and seven slave nodes (“2” ,“3” , ...and “8”).

Using (91) is possible to write the displacement of the slave node “\({\text {a}}_{1}\)” as a function of the displacement of the master node “a” for EFOCH as

To simplify the final expressions is defined

Therefore, it can be shown that the slaves nodes are

And, taking into account that the position vector of the master vertex node “1” is: \({\mathbf {X}}_{1}=\,-\frac{D_{1}}{2}{\mathbf {N}}_{X}^{+}-\frac{D_{2}}{2}{\mathbf {N}}_{Y}^{+}-\frac{D_{3}}{2}{\mathbf {N}}_{Z}^{+}\), the slaves vertices nodes are

The extra boundary restrictions must be also satisfied. These boundary conditions are integral boundary constraints on each negative face of the RVE. Equation (92) can be rewritten as

where,

and,

Here, \({\mathbf {N}}_{yz}\), \({\mathbf {N}}_{xz}\) and \({\mathbf {N}}_{xy}\) are the shape functions on the negative face YZ, XZ and XY of the RVE, respectively. And, from Fig. 18 it is possible to write the displacement vectors of the nodes on the different negative faces as

In the previous displacement vectors of the nodes on the negative faces of the RVE it is possible identify masters and slaves nodes. Therefore, the boundary constraints (95) obtained above can be written in terms of master nodes as

where,

and, as an example, the term of the matrix \({\mathbf {A}}^{m}_{yz}\) for the \(\bar{{\mathbf {u}}}_{b}\) of the master nodes on the negative face YZ is

and the contribution to \({\mathbf {H}}^{m}_{yz}\) for the \(\bar{{\mathbf {u}}}_{b_{3}}\) of the slave nodes on the negative face YZ is

The master nodes on the different negative faces of the RVE must verify (96). Therefore, with the aim to find redundant unknowns, it is possible to identify another slave extra node by each negative face which can be obtained as a function of the other master nodes. Then,

Rights and permissions

About this article

Cite this article

Otero, F., Oller, S. & Martinez, X. Multiscale Computational Homogenization: Review and Proposal of a New Enhanced-First-Order Method. Arch Computat Methods Eng 25, 479–505 (2018). https://doi.org/10.1007/s11831-016-9205-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11831-016-9205-0