Abstract

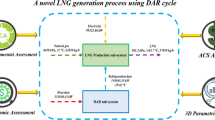

An integrated LNG regasification - air separation process is investigated using exergy and exergoeconomic analyses. The objective of developing this integrated process is to lower the calorific value of LNG by mixing regasified LNG with high purity nitrogen, while simultaneously recovering and utilizing valuable cryogenic energy from the LNG during its regasification to minimize the power consumption of the air separation unit (ASU) for nitrogen production. The overall exergy efficiency and exergy destruction of the integrated process are 76.47% and 28.52 MW, respectively, with the compression section causing the most exergy destruction. Further exergoeconomic analysis of the proposed process reveals that the air compressors have the highest capital investment (CI) and operating and maintenance (O&M) cost rates, the pumps for cooling water and LNG have the highest exergoeconomic factors, and the low-pressure column and a multistream heat exchanger have the highest exergy destruction cost rates. A parametric study is also conducted to examine the impact of economic variables including interest rate, plant life, and compressor performance on exergy destruction, CI and O&M cost rates, and exergoeconomic factor. The findings of this study offer valuable insight into the design and optimization of similar integrated processes, with potential benefits for the energy industry.

Similar content being viewed by others

Abbreviations

- A:

-

area [m2]

- C:

-

cost rate [$/h]

- Cd, k :

-

exergy destruction cost rate for equipment k [$/h]

- Cf, k :

-

exergy destruction cost rate for an inlet stream to equipment k [$/h]

- Cp, k :

-

exergy destruction cost rate for an outlet stream from equipment k [$/h]

- c:

-

cost per unit exergy [$/GJ]

- cf, k :

-

cost per unit exergy for an inlet stream to equipment k [$/GJ]

- cp, k :

-

cost per unit exergy for an outlet stream from equipment k [$/GJ]

- D:

-

diameter of the vessel [m]

- E:

-

exergy of a stream

- Echem :

-

chemical exergy of a stream [kW]

- Ephy :

-

physical exergy of a stream [kW]

- Etot :

-

total exergy of a stream [kW]

- Ein :

-

exergy of an inlet stream [kW]

- Eout :

-

exergy of an outlet stream [kW]

- Ed, k :

-

exergy destruction in equipment k [kW]

- Ef, k :

-

exergy of an inlet stream to equipment k [kW]

- Ep, k :

-

exergy of an outlet stream from equipment k [kW]

- Eq :

-

exergy corresponding to heat flow \(({\rm{kW}}) = Q\left( {{{{{\rm{T}}_0}} \over {\rm{T}}} - 1} \right)\)

- fk :

-

exergoeconomic factor [%]

- F:

-

flow rate [TPH, tons per hour]

- FD :

-

driver (electric motor, steam turbine, etc.) factor

- FM :

-

material factor

- H:

-

annual working hours [h]

- i:

-

interest rate [%]

- L:

-

length/tangent to tangent height of the vessel [m]

- N:

-

plant lifetime [years]

- n:

-

number of trays

- PEC:

-

purchased equipment cost [$]

- Po :

-

reference pressure [1.01325 bar]

- Pc :

-

power [kW]

- Q:

-

heat flow [kW]

- rk :

-

relative cost difference [%]

- ΔTmin :

-

minimum approach temperature [K]

- To :

-

reference temperature [298.15 K]

- W:

-

mechanical work [kW]

- Wp :

-

work required by the pump [kW]

- Win :

-

work required (for pumps and compressors) [kW]

- Wout :

-

work produced (from turbine) [kW]

- Y D, k :

-

exergy destruction ratio [%]

- Z k :

-

investment cost rate [$/h]

- ε k :

-

exergy efficiency [%]

- η p :

-

pump efficiency [%]

- f:

-

feed

- P:

-

product

- k:

-

k-th equipment

- ASU:

-

air separation unit

- CI:

-

capital investment

- EES:

-

engineering equation solver

- HP:

-

horsepower

- LNG:

-

liquefied natural gas

- LMTD:

-

log mean temperature difference

- O&M:

-

operations and maintenance

- TPH:

-

tons per hour

References

A. Atienza-Márquez, J. C. Bruno and A. Coronas, Appl. Therm. Eng., 132, 463 (2018).

J. Pospíšil, P. Charvát, O. Arsenyeva, L. Klimeš, M. Špiláček and J. J. Klemeš, Renew. Sust. Energy Rev., 99, 1 (2019).

A. Mahmood, N. Javaid, A. Zafar, R. A. Riaz, S. Ahmed and S. Razzaq, Renew. Sust. Energy Rev., 31, 182 (2014).

K. Bakht, F. Aslam, T. Nawaz and B. Seerat, Int. J. Adv. Comput. Sci. Appl., 7, 66 (2016).

Exxon Mobil Corporation, 2019 Outlook for Energy: A Perspective to 2040 (2019).

U. Perwez, A. Sohail, S. F. Hassan and U. Zia, Energy, 93, 2423 (2015).

S. Malik, M. Qasim, H. Saeed, Y. Chang and F. Taghizadeh-Hesary, Energy Policy, 144, 111552 (2020).

Ministry of Planning Development & Special Initiatives (Government of Pakistan), Pakistan Natural Gas: Policy Analysis & Way Forward, Islamabad, Pakistan (2023).

British Petroleum, BP Statistical Review of World Energy 2021 (2021).

National Electric Power Regulatory Authority (NEPRA), State of Industry Report 2022, Islamabad, Pakistan (2022).

P. Dorosz, P. Wojcieszak and Z. Malecha, Entropy, 20, 59 (2018).

D. Fioriti, A. Baccioli, G. Pasini, A. Bischi, F. Migliarini, D. Poli and L. Ferrari, Energy Convers. Manage., 238, 114128 (2021).

I. Szczygiel and Z. Bulinski, Energy, 165, 999 (2018).

J. Bao, T. Yuan, L. Zhang, N. Zhang, X. Zhang and G. He, Energy Convers. Manage., 184, 107 (2019).

M. Mehrpooya, M. Kalhorzadeh and M. Chahartaghi, J. Cleaner Prod., 113, 411 (2016).

A. Ebrahimi and M. Ziabasharhagh, Energy, 126, 868 (2017).

D. Kim, R. E. H. Giametta and T. Gundersen, Ind. Eng. Chem. Res., 57, 5914 (2018).

T. Gao, W. Lin and A. Gu, Energy Convers. Manage., 52, 2401 (2011).

G. Tsatsaronis and T. Morosuk, Energy, 35, 820 (2010).

M. Mehrpooya, R. Esfilar and S. M. A. Moosavian, J. Cleaner Prod., 142, 1749 (2017).

S. Chen, J. Xu, X. Dong, H. Zhang, Q. Gao and C. Tan, Int. J. Refrig., 90, 264 (2018).

H. Dhameliya and P. Agrawal, Energy Procedia, 90, 660 (2016).

P. Wang and T.-S. Chung, Water Res., 46, 4037 (2012).

C. Dispenza, G. Dispenza, V. La Rocca and G. Panno, Appl. Therm. Eng., 29, 3595 (2009).

I. Lee, J. Park and I. Moon, Energy, 140, 106 (2017).

Confidential, Design specification of a gas-fired power plant in Pakistan (n.d.).

M. Mehrpooya and H. Ansarinasab, Energy Convers. Manage., 99, 400 (2015).

S. Kumar, H.-T. Kwon, K.-H. Choi, W. Lim, J. H. Cho, K. Tak and I. Moon, Appl. Energy, 88, 4264 (2011).

Y. Xiong and B. Hua, Adv. Mater. Res., 881–883, 653 (2014).

T. He, Z. R. Chong, J. Zheng, Y. Ju and P. Linga, Energy, 170, 557 (2019).

S. Wang, K. Huang, X. Wang, N. Liao, W. Yan, Q. Pei and B. Xia, Open Pet. Eng. J., 9, 226 (2016).

A. Ebrahimi, M. Meratizaman, H. A. Reyhani, O. Pourali and M. Amidpour, Energy, 90, 1298 (2015).

M. H. Hamayun, N. Ramzan, M. Hussain and M. Faheem, Ind. Eng. Chem. Res., 61, 2843 (2022).

Q. Fu, Y. Kansha, C. Song, Y. Liu, M. Ishizuka and A. Tsutsumi, Appl. Energy, 162, 1114 (2016).

M. Elhelw, A. A. Alsanousie and A. Attia, Alexandria Eng. J., 59, 613 (2020).

S. Chen, X. Dong, J. Xu, H. Zhang, Q. Gao and C. Tan, Energy, 171, 341 (2019).

M. Mehrpooya, H. Dehghani and S. M. A. Moosavian, J. Power Sources, 306, 107 (2016).

H. Ansarinasab and M. Mehrpooya, Appl. Therm. Eng., 115, 885 (2017).

A. Mohammadi and M. Mehrpooya, Appl. Therm. Eng., 116, 685 (2017).

M. J. Zonouz and M. Mehrpooya, Energy, 140, 261 (2017).

H. Ansarinasab, M. Mehrpooya and A. Mohammadi, J. Cleaner Prod., 144, 248 (2017).

M. Mehrpooya, H. Ansarinasab, M. M. M. Sharifzadeh and M. A. Rosen, Energy Convers. Manage., 163, 151 (2018).

W. Xu, J. Duan and W. Mao, J. Therm. Sci., 23, 77 (2014).

T. Morosuk, M. Schult and G. Tsatsaronis, in ASME 2014 8th International Conference on Energy Sustainability, ASME, Boston, Massachusetts, USA, p. V002T12A010 (2014).

Z. Jieyu, L. Yanzhong, L. Guangpeng and S. Biao, Phys. Procedia, 67, 116 (2015).

M. Mehrpooya, M. M. M. Sharifzadeh and M. A. Rosen, Energy, 90, 2047 (2015).

R. Esfilar, M. Mehrpooya and S. M. A. Moosavian, Energy Convers. Manage., 157, 438 (2018).

M. Mehrpooya and H. Ansarinasab, J. Nat. Gas Sci. Eng., 26, 782 (2015).

B. Ghorbani, M.-H. Hamedi, R. Shirmohammadi, M. Hamedi and M. Mehrpooya, Sust. Energy Technol. Assess., 17, 56 (2016).

M. Mehrpooya and M. J. Zonouz, Energy Convers. Manage., 139, 245 (2017).

M. Mehrpooya, H. Ansarinasab, M. M. M. Sharifzadeh and M. A. Rosen, J. Power Sources, 364, 299 (2017).

Aspentech, Aspen plus is a proprietary software product of Aspentech, https://www.Aspentech.Com.

T. J. Kotas, The exergy method of thermal plant analysis, Elsevier (1985).

S. Tesch, T. Morosuk and G. Tsatsaronis, Energy, 141, 2458 (2017).

A. Palizdar, T. Ramezani, Z. Nargessi, S. AmirAfshar, M. Abbasi and A. Vatani, Energy Convers. Manage., 150, 637 (2017).

M. H. Hamayun, N. Ramzan, M. Hussain and M. Faheem, Energies, 13, 6361 (2020).

F. Asif, M. H. Hamayun, M. Hussain, A. Hussain, I. M. Maafa and Y.-K. Park, Sustainability, 13, 6490 (2021).

M. H. Hamayun, M. Hussain, I. Shafiq, A. Ahmed and Y.-K. Park, Environ. Eng. Res., 27, 200683 (2022).

B. B. Kanbur, L. Xiang, S. Dubey, F. H. Choo and F. Duan, Renew. Sust. Energy Rev., 79, 1171 (2017).

V. M. Ambriz-Díaz, C. Rubio-Maya, E. Ruiz-Casanova, J. Martínez-Patiño and E. Pastor-Martínez, Energy Convers. Manage., 203, 112227 (2020).

C. J. Okereke, O. Lasode and I. O. Ohijeagbon, Heliyon, 6, e04402 (2020).

H. Ozcan and I. Dincer, Int. J. Hydrogen Energy, 42, 2435 (2017).

J. R. Couper, W. R. Penney, J. R. Fair and S. M. Walas, Chemical process equipment: Selection and design, 3rd ed., Elsevier (2012).

W. D. Seider, D. R. Lewin, J. D. Seader, S. Widagdo, R. Gani and K. M. Ng, Product and process design principles: Synthesis, analysis, and evaluation, 4th ed., John Wiley & Sons, Inc. (2017).

V. Eveloy, W. Karunkeyoon, P. Rodgers and A. Al-Alili, Int. J. Hydrogen Energy, 41, 13843 (2016).

R. Turton, R. C. Bailie, W. B. Whiting, J. A. Shaeiwitz and D. Bhattacharyya, Analysis, synthesis, and design of chemical processes, 4th ed., Prentice Hall (2012).

G. Tsatsaronis, Int. J. Exergy, 5, 489 (2008).

M. Ameri, P. Ahmadi and A. Hamidi, Int. J. Energy Res., 33, 499 (2009).

C. Uysal, Environ. Prog. Sust. Energy, 39, e13297 (2020).

Acknowledgement

The authors gratefully acknowledge the financial support of the SNGPL Chair of Gas Engineering in the Department of Chemical Engineering, University of Engineering & Technology, Lahore.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Supporting Information

Additional information as noted in the text. This information is available via the Internet at http://www.springer.com/chemistry/journal/11814.

Supporting Information

Rights and permissions

About this article

Cite this article

Hamayun, M.H., Ramzan, N. & Faheem, M. Exergoeconomic analysis of an LNG integrated - air separation process. Korean J. Chem. Eng. 40, 3017–3028 (2023). https://doi.org/10.1007/s11814-023-1567-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-023-1567-z