Abstract

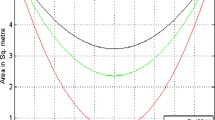

Extrusion pressure is crucial for the security and performance of a cylindrical extruder during the extrusion process. In this study, a validated CFD model was adopted to evaluate the relationship between the extrusion velocity, fluid viscosity, and the extrusion pressure of a cylindrical extruder while extruding highly viscous fluids. The simulated and experimental results of the extrusion pressure and velocity profiles show good agreement. This study reveals that extrusion pressure evolution can be divided into two stages during the extrusion process. At stage I, the distance between the ram and the bottom of the vessel (liquid height) is greater than the critical height and the extrusion pressure remains almost constant. At stage II, the distance is less than the critical height and the extrusion pressure increases exponentially. The results indicate that an increase in extrusion velocity and fluid viscosity leads to a linear increase in the extrusion pressure at stage I. Furthermore, by introducing a pressure number, Np, and a pressure-related Reynolds number, Rep, a novel correlation of the extrusion pressure with the extrusion velocity, viscosity of highly viscous fluids and liquid height has been developed.

Similar content being viewed by others

Abbreviations

- b:

-

exponent [dimensionless]

- d:

-

diameter of the die land [mm]

- D:

-

diameter of the vessel [mm]

- F:

-

external body forces other than pressure [N/m3]

- \(\overset{\rightharpoonup}{{\rm{g}}}\) :

-

gravitational acceleration [m/s2]

- H:

-

distance between ram and bottom of the vessel (liquid height) [mm]

- Hc :

-

the critical height (mm)

- KpI :

-

the extrusion pressure index at stage I [dimensionless]

- KpII :

-

the extrusion pressure index at stage II [dimensionless]

- L:

-

length of the die land [mm]

- m:

-

exponent for velocity-dependent yield stress [dimensionless]

- n:

-

exponent for velocity-dependent wall shear stress [dimensionless]

- Np :

-

pressure number [dimensionless]

- p:

-

the fluid pressure [Pa]

- P ex :

-

extrusion pressure [Pa]

- PexI :

-

extrusion pressure at stage I [Pa]

- PexII :

-

extrusion pressure at stage II [Pa]

- Rep :

-

pressure-related number [dimensionless]

- t:

-

time [s]

- \(\overset{\rightharpoonup}{{\rm{v}}}\) :

-

velocity vector [m/s]

- vdie :

-

fluid velocity in die land [mm/s]

- vram :

-

extrusion velocity [mm/s]

- α :

-

velocity coefficient for yield stress [Pa/(m/s)m]

- β :

-

wall slip shear rate coefficient [Pa/(m/s)n]

- γ̇ :

-

volume-averaged shear rate of the fluid domain [1/s]

- μ :

-

viscosity [Pa s]

- ρ :

-

density [kg/m3]

- σ 0 :

-

the yield stress [Pa]

- τ :

-

volume-averaged shear stress of the fluid domain [Pa]

- τ 0 :

-

wall slip yield stress [Pa]

- CFD:

-

computational fluid dynamics

- PIV:

-

Particle Image Velocity

References

S. Naumann, U. Schweiggert-Weisz, A. Martin, M. Schuster and P. Eisner, Food Hydrocolloid., 111, 106222 (2021).

N. Vitorino, M. J. Ribeiro, J. C. C. Abrantes, J. A. Labrincha and J. R. Frade, Ceram. Int., 40, 14543 (2014).

T. O. Althaus and E. J. Windhab, Powder Technol., 211, 10 (2011).

S. Mascia, M. J. Patel, S. L. Rough, P. J. Martin and D. I. Wilson, Eur. J. Pharm. Sci., 29, 22 (2006).

K. Prabha, P. Ghosh, S. Abdullah, R. M. Joseph, R. Krishnan, S. S. Rana and R. C. Pradhan, Future Foods, 3, 100019 (2021).

Y. S. Lee and O. O. Park, Korean J. Chem. Eng., 11, 1 (1994).

R. A. Basterfield, C. J. Lawrence and M. J. Adams, Chem. Eng. Sci., 60, 2599 (2005).

H. Khelifi, A. Perrot, T. Lecompte, D. Rangeard and G. Ausias, Powder Technol., 249, 258 (2013).

M. Cortada-Garcia, W. H. Weheliye, V. Dore, L. Mazzei and P. Angeli, Chem. Eng. Sci., 179, 133 (2018).

G. Yang, A. Terzis, I. Zarikos, S. M. Hassanizadeh, B. Weigand and R. Helmig, Chem. Eng. J., 370, 444 (2019).

J. Jin and Y. Fan, Korean J. Chem. Eng., 37, 755 (2020).

A. Silva, F. J. G. Silva, R. D. S. G. Campilho and P. M. P. F. Neves, J. Manuf. Processes, 65, 80 (2021).

H. Zhang, X. Zhao, X. Deng, M. A. Sutton, A. P. Reynolds, S. R. McNeill and X. Ke, Int. J. Mech. Sci., 85, 130 (2014).

M. P. Serdeczny, R. Comminal, M. T. Mollah, D. B. Pedersen and J. Spangenberg, Additive Manuf., 36, 101454 (2020).

C. Soanuch, K. Korkerd, J. Phupanit, R. Piemjaiswang, P. Piumsomboon and B. Chalermsinsuwan, Korean J. Chem. Eng., 38, 540 (2021).

P. Jay, A. Magnin and J. M. Piau, J. Fluids Eng., 124, 700 (2002).

Q. Liu, N. Zhang, W. Wei, X. Hu, Y. Tan, Y. Yu, Y. Deng, C. Bi, L. Zhang and H. Zhang, J. Food Eng., 275, 109861 (2020).

D. J. Ryan, M. J. H. Simmons and M. R. Baker, Chem. Eng. Sci., 163, 123 (2017).

D. J. Horrobin and R. M. Nedderman, Chem. Eng. Sci., 53, 3215 (1998).

T. Jiang, J.G. Munguia-Lopez, S. Flores-Torres, J. Kort-Mascort and J. M. Kinsella, Appl. Phys. Rev., 6, 11310 (2019).

M. J. Ribeiro, S. Blackburn, J. M. Ferreira and J. A. Labrincha, J. Eur. Ceram. Soc., 26, 817 (2006).

Y. Y. Li and J. Bridgwater, Powder Technol., 108, 65 (2000).

Z. Lin, T. Jiang, J. M. Kinsella, J. Shang and Z. Luo, Mater. Lett., 303, 130480 (2021).

J. J. Benbow, E. W. Oxley and J. Bridgwater, Chem. Eng. Sci., 42, 2151 (1987).

C. Bhattacharjee, Korean J. Chem. Eng., 21, 556 (2004).

K. Lachin, C. Turchiuli, V. Pistre, G. Cuvelier, S. Mezdour and F. Ducept, Chem. Eng. Res. Des., 163, 36 (2020).

C. André, J. F. Demeyre, C. Gatumel, H. Berthiaux and G. Delaplace, Chem. Eng. J., 198–199, 371 (2012).

M. Davarpanah, H. Shi, P. Nikrityuk and Z. Hashisho, Chem. Eng. Res. Des., 173, 289 (2021).

S. L. Rough, D. I. Wilson and J. Bridgwater, Chem. Eng. Res. Des., 80, 701 (2002).

K. E. Ryltseva, E. I. Borzenko and G. R. Shrager, J. Non-Newton. Fluid, 286, 104445 (2020).

H. Bouras, Y. Haroun, R. Philippe, F. Augier and P. Fongarland, Chem. Eng. Sci., 233, 116378 (2021).

R. K. Connelly and J. L. Kokini, J. Food Eng., 79, 956 (2007).

E. Bumrungthaichaichan, Korean J. Chem. Eng., 33, 3050 (2016).

H. Liu, J. Liu, M. C. Leu, R. Landers and T. Huang, Int. J. Adv. Manuf. Technol., 67, 899 (2013).

Y. Sun, J. Yu, W. Wang, S. Yang, X. Hu and J. Feng, Korean J. Chem. Eng., 37, 743 (2020).

F. Keramat, A. Mirvakili, A. Shariati and M. R. Rahimpour, Korean J. Chem. Eng., 38, 2020 (2021).

S. I. Choi, J. P. Feng, H. S. Seo, Y. M. Jo and H. C. Lee, Korean J. Chem. Eng., 35, 2164 (2018).

W. Han and X. Chen, Chem. Eng. Res. Des., 145, 213 (2019).

S. Melzi, Comput. Graphics, 82, 117 (2019).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, Z., Shen, B., He, Y. et al. Analysis of the extrusion pressure of a cylindrical extruder for extruding highly viscous fluids. Korean J. Chem. Eng. 39, 2623–2635 (2022). https://doi.org/10.1007/s11814-022-1191-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-022-1191-3