Abstract

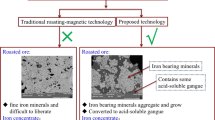

Suspension magnetizing roasting-magnetic separation technology was used to extract iron from fine-grained complex hematite ore. The effect of roasting conditions on the magnetizing roasting-magnetic separation process was studied. In summary, a concentrate with TFe grade of 69.96% and Fe recovery of 79.02% could be obtained under conditions of a roasting temperature of 500 °C, roasting time was 12 min, reductant concentration of 30%, and total gas flow of 200 mL/min, while TFe grade of final tailings was 5.66%. The phase composition and X-ray photoelectron spectroscopy analysis showed that hematite in the sample was transformed into magnetite during suspension magnetization roasting. After roasting, the proportion of Fe content in the phase of the magnetite increased from 5.91% in roasting feed to 97.96% in the roasting product. Transmission electron microscopy results also confirmed that hematite was transformed into magnetite with spinel structure, and the newly formed magnetite had good crystallinity. Scanning electron microscopy and BET analysis showed that roasting could increase the specific surface area, total pore volume, and porosity of the roasted product, which would strengthen the internal diffusion of CO and CO2 in the particles, to improve the reduction rate of hematite. The loose internal structure of roasted particles led to the decrease of mechanical properties, which was conducive to improving the subsequent grinding efficiency.

Similar content being viewed by others

References

S. Patra, A. Pattanaik and V. Rayasam, Can Metall Q., 58, 28 (2019).

J. W. Yu, Y. X. Han, Y. J. Li, P. Gao and Y. S. Sun, Sep. Sci. Technol., 52, 1768 (2017).

Y. S. Sun, X. L. Zhang, Y. X. Han and Y. J. Li, Powder Technol., 361, 571 (2020).

D. Komljenovic, L. Stojanovic, V. Malbasic and A. Lukic, Int. J. Min. Sci. Technol., 30, 737 (2020).

Z. Y. Lan, Z. N. Lai, Y. X. Zheng, J. F. Lv, J. Pang, J. L. Ning, J. Cent. South Univ., 27, 37 (2020).

J. W. Yu, Y. X. Han, P. Gao, Y. J. Li, S. Yuan and W. B. Li, Physico-chem. Probl. Mineral Pro., 54, 668 (2018).

G. B. Abaka-Wood, M. Zanin, J. Addai-Mensah and W. Skinner, Miner. Eng., 142, 105888 (2019).

J. He, L. Zhu, X. Bu, C. Liu, Z. Luo and Y. Yao, Chem. Eng. Process., 138, 27 (2019).

R. M. F. Lima and F. D. V. F. Abreu, J. Mater. Res. Technol-JMRT, 9, 2021 (2020).

W.-w. Wang and Z.-y. Li, Miner. Eng., 155, 106453 (2020).

E. Matiolo, H. J. B. Couto, N. Lima K. Silva and A. S. de Freitas, Miner. Eng., 158, 106608 (2020).

W. Li, L. Zhou, Y. Han, Y. Zhu and Y. Li, Powder Technol., 343, 270 (2019).

J. F. He, C. G. Liu, J. Q. Xie, P. Hong and Y. K. Yao, Powder Technol., 319, 346 (2017).

Y. Yao, Q. Bai, J. He, L. Zhu, K. Zhou and Y. Zhao, Waste Manage., 103, 218 (2020).

Z. Gao, X. Chai, E. Zhou, Y. Jia, C. Duan and L. Tang, Int. J. Min. Sci. Technol., 30, 883 (2020).

S. S. Rath, H. Sahoo, N. Dhawan, D. S. Rao, B. Das and B. K. Mishra, Sep. Sci. Technol., 49, 1927 (2014).

F. F. Wu, Z. F. Cao, S. Wang and H. Zhong, J. Alloy. Compd., 722, 651 (2017).

S. D. Lu, S. H. Ju, J. H. Peng and X. P. Zhu, High Temp. Mater. Process., 34, 147 (2015).

C. Xu, H. W. Cheng, G. S. Li, C. Y. Lu, X. G. Lu, X. L. Zou and Q. Xu, Int. J. Miner. Metall. Mater., 24, 377 (2017).

Z. D. Tang, P. Gao, Y. X. Han and W. Guo, J. Min. Metall. Sect. B-Metall., 55, 295 (2019).

E. Donskoi, A. F. Collings, A. Poliakov and W. J. Bruckard, Int. J. Miner. Process., 114, 80 (2012).

W. Zhou, Y. Sun, Y. Han, P. Gao and Y. Li, Miner. Eng., 164, 106851 (2021).

Y. Qin, Y. Han, P. Gao, Y. Li and S. Yuan, Miner. Eng., 160, 106662 (2021).

Y. S. Sun, X. R. Zhu, Y. X. Han, Y. J. Li and P. Gao, J. Clean Prod., 261, 121221 (2020).

Y. Li, Q. Zhang, S. Yuan and H. Yin, Powder Technol., 379, 466 (2021).

P. Gao, Z. D. Tang, Y. X. Han, E. L. Li and X. L. Zhang, Powder Technol., 343, 255 (2019).

Z. D. Tang, P. Gao, Y. J. Li, Y. X. Han, W. B. Li, S. Butt and Y. H. Zhang, Powder Technol., 361, 591 (2020).

S. Yuan, Q. Zhang, H. Yin and Y. Li, J. Hazard. Mater., 404, 124067 (2021).

H. T. B. M. Petrus, A. D. P. Putera, E. Sugiarto, I. Perdana, I. W. Warmada, F. Nurjaman, W. Astuti and A. T. Mursito, Miner. Eng., 132, 126 (2019).

V. P. Ponomar, N. O. Dudchenko and A. B. Brik, Miner. Eng., 122, 277 (2018).

Acknowledgements

The authors are extremely grateful for the financial support received from the National Natural Science Foundation of China (Grant Nos. 51734005 and 51904058), the Fundamental Research Funds for the Central Universities (N2101023), and the Open Foundation of State Key Laboratory of Mineral Processing (Grant No. BGRIMM-KJSKL-2020-17).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yuan, S., Wang, R., Zhang, Q. et al. Extraction and phase transformation of iron in fine-grained complex hematite ore by suspension magnetizing roasting and magnetic separation. Korean J. Chem. Eng. 39, 1891–1901 (2022). https://doi.org/10.1007/s11814-022-1116-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-022-1116-1