Abstract

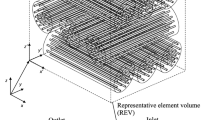

EVA is an important high-performance resin material obtained by the copolymerization of ethylene and vinyl acetate. In the present study, a comprehensive computational fluid dynamics (CFD) model was established to study the EVA free radical copolymerization process. The polymerization kinetic model was combined with the CFD model. The EVA copolymerization reaction mechanism was verified by comparing the simulation results with the experimental results. Detailed information of the flow field inside the industrial EVA autoclave reactor was obtained. With the increase of the impeller speed, both the axial and radial flows inside the autoclave reactor were enhanced. The high impeller speed improved the fluid mixing and the homogeneity of temperature distribution. The increase of the impeller speed improved the initiator dispersion near the inlets, thereby increasing the efficiency of the initiator. The influence of operating conditions on monomer conversion and specific initiator consumption per 1% of the monomer reacted was investigated. The simulation results give deep insight into the free radical copolymerization process inside the autoclave reactor and supply the guidelines for developing an industrial autoclave reactor.

Similar content being viewed by others

Abbreviations

- A:

-

modifier

- D m,i :

-

diffusion coefficient of component m [m2·s−1]

- Ea :

-

activation energy [J·mol−1·K−1]

- e:

-

total energy [J·kg−1]

- f:

-

apparent initiator efficiency factor

- h:

-

specific enthalpy [J·kg−1]

- Jm,i :

-

diffusion flux of component m [kg·m−2·s−1]

- k:

-

turbulent kinetic energy [J·kg−1·s−1]

- k0 :

-

frequency factor [s−1 or L·mol−1·s−1]

- kd :

-

initiator decomposition rate coefficient [L·s−1]

- keff :

-

effective thermal conductivity [W·m−1·K−1]

- kin :

-

initiation rate coefficient [L·mol−1·s−1]

- kp :

-

propagation rate coefficient [L·mol−1·s−1]

- kta :

-

chain transfer to modifier rate coefficient [L·mol−1·s−1]

- ktc :

-

termination by combination rate coefficient [L·mol−1·s−1]

- ktd :

-

termination by disproportionation rate coefficient [L·mol−1·s−1]

- ktm :

-

chain transfer to monomer rate coefficient [L·mol−1·s−1]

- ktp :

-

chain transfer to polymer rate coefficient [L·mol−1·s−1]

- kβ :

-

β-scission of internal radicals rate coefficient [L·mol−1·s−1]

- MT :

-

stirring torque [N·m]

- N:

-

impeller speed [rpm]

- PV :

-

impeller power consumption per unit volume [W·m−3]

- p:

-

pressure [Pa]

- r:

-

reaction rate [mol·L−1·s−1]

- Sh :

-

heat source term due to polymerization [J·m−3·s−1]

- Si :

-

reaction source of component i [J·m−3·s−1]

- Sct :

-

Schmidt number

- T:

-

temperature [K]

- ui :

-

velocity components [m·s−1]

- V:

-

reactor volume [m3]

- WI :

-

the specific initiator consumption per 1% of the monomer reacted [kg·h−1]

- Ym :

-

mass fraction of component m

- ∆T:

-

the outlet temperature rise [K]

- ∆V:

-

activation volume [cm3·mol−1]

- δ ij :

-

Kronecker delta

- ε :

-

Turbulent kinetic energy dissipation rate [J·kg−1·s−1]

- λ i :

-

moment of the live polymer chains [mol·L−1]

- μ i :

-

moment of the dead polymer chains [mol·L−1]

- μ :

-

dynamic viscosity [Pa·s]

- μ t :

-

turbulent viscosity [Pa·s]

- ρ :

-

mixture density [kg·m−3]

- τ ij :

-

stress tensor [Pa]

- d:

-

initiation decomposition

- in:

-

initiator

- m:

-

chain length

- n:

-

chain length

- p:

-

propagation

- ta:

-

chain transfer to modifier

- tc:

-

termination by combination

- td:

-

termination by disproportionation

- tm:

-

chain transfer to monomer

- tp:

-

chain transfer to polymer

- z:

-

chain length

- β :

-

β-scission of internal radicals

References

S. P. Tambe, S. K. Singh, M. Patri and D. Kumar, Prog. Org. Coat., 62, 382 (2008).

A. Zarrouki, E. Espinosa, C. Boisson and V. Monteil, Macromolecules, 50, 3516 (2017).

M. Ghiass and R. A. Hutchinson, Polym. React. Eng., 11, 989 (2003).

G. J. Wells and W. H. Ray, AIChE J., 51, 3205 (2005).

P. Pladis and C. A. Kiparissides, Ind. Eng. Chem. Res., 58, 13093 (2019).

C. Kiparissides, G. Verros and J. A. Macgregor, J. Macromol. Sci., Polym. Rev., 33, 437 (1993).

Y. Lee, K. Jeon, J. Cho, J. Na, J. Park, I. Jung, J. Park, M. J. Park and W. B. Lee, Ind. Eng. Chem. Res., 58, 16459 (2019).

H. Patel, R. Dhib and F. Ein-Mozaffari, Chem. Eng. Technol., 33, 258 (2010).

S. F. Roudsari, F. Ein-Mozaffari and R. Dhib, Chem. Eng. J., 219, 429 (2013).

C. Xu, J. Wang, X. Gu and L. Feng, Chem. Eng. Commun., 205, 857 (2018).

G. J. Wells and W. H. Ray, Macromol. Mater. Eng., 290, 319 (2005).

G. Luft, M. Jabbari and M. Dorn, Angew. Makromol. Chem., 238, 87 (1996).

I. L. Chien, T. W. Kan and B.-S. Chen, Comput. Chem. Eng., 31, 233 (2007).

N. Jacob and R. Dhib, J. Ind. Eng. Chem., 18, 1781 (2012).

C. Sarmoria, A. Brandolin, A. Lopez-Rodriguez, K. S. Whiteley and B. D. Fernandez, Polym. Eng. Sci., 40, 1480 (2000).

J. Cui, L. Ni, J. Jiang, Y. Pan, H. Wu and Q. Chen, Org. Process Res. Dev., 23, 389 (2019).

N. K. Read, S. X. Zhang and W. H. Ray, AIChE J., 43, 104 (1997).

G. D. Wehinger, T. Eppinger and M. Kraume, Chem. Eng. Sci., 122, 197 (2015).

Y. Zhuang, X. Gao, Y. Zhu and Z. Luo, Powder Technol., 221, 419 (2012).

T. Shin, W. W. Liou, A. Shabbir, Z. Yang and J. Zhu, Comput. Fluids, 24, 227 (1995)

P. Becker, M. Buback and J. Sandmann, Macromol. Chem. Phys., 203, 2113 (2002).

T. Xie and A. Hamielec, Macromol. Theory Simul., 2, 777 (1993).

T. Xie and A. Hamielec, Macromol. Theory Simul., 2, 455 (1993).

T. Xie and A. Hamielec, Macromol. Theory Simul., 2, 421 (1993).

A. Hamielec, J. MacGregor and A. Penlidis, Makromolekulare Chemie. Macromol. Symp., 10–11, 521 (1987).

J. Soares, Chem. Eng. Sci., 56, 4131 (2001).

P. Pladis and C. Kiparissides, Chem. Eng. Sci., 53, 3315 (1998).

H. Hulburt and S. Katz, Chem. Eng. Sci., 19, 555 (1964).

S. Roudsari, G. Turcotte, R. Dhib and F. Ein-Mozaffari, Comput. Chem. Eng., 45, 124 (2012).

S. Zhang and W. Ray, AIChE J., 43, 1265 (1997).

C. He, J. Wang, R. Wang and X. Zhang, Renew. Energ., 168, 1177 (2021).

S. Erdogan, M. Alpbaz and A. R. Karagöz, Chem. Eng. J., 86, 259 (2002).

Author information

Authors and Affiliations

Corresponding author

Additional information

Supporting Information

Additional information as noted in the text. This information is available via the Internet at http://www.springer.com/chemistry/journal/11814.

Supporting Information

11814_2022_1075_MOESM1_ESM.pdf

Investigation on flow characteristic and reaction process inside an EVA autoclave reactor using CFD modeling combined with polymerization kinetics

Rights and permissions

About this article

Cite this article

Wang, Y., Liu, C., Wang, S. et al. Investigation on flow characteristic and reaction process inside an EVA autoclave reactor using CFD modeling combined with polymerization kinetics. Korean J. Chem. Eng. 39, 1384–1395 (2022). https://doi.org/10.1007/s11814-022-1075-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-022-1075-6