Abstract

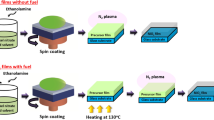

Plasma-enhanced atomic layer deposition (PEALD) is well-known for fabricating conformal and uniform films with a well-controlled thickness at the atomic level over any type of supporting substrate. We prepared nickel oxide (NiO) thin films via PEALD using bis(ethylcyclopentadienyl)-nickel (Ni(EtCp)2) and O2 plasma. To optimize the PEALD process, the effects of parameters such as the precursor pulsing time, purging time, O2 plasma exposure time, and power were examined. The optimal PEALD process has a wide deposition-temperature range of 100–325 °C and a growth rate of 0.037±0.002 nm per cycle. The NiO films deposited on a silicon substrate with a high aspect ratio exhibited excellent conformality and high linearity with respect to the number of PEALD cycles, without nucleation delay.

Similar content being viewed by others

References

P. Rai, J. W. Yoon, H. M. Jeong, S. J. Hwang, C. H. Kwak and J. H. Lee, Nanoscale, 6, 8292 (2014).

J. Wang, L. Wei, L. Zhang, J. Zhang, H. Wei, C. Jiang and Y. Zhang, J. Mater. Chem., 22, 20038 (2012).

R. Betancur, M. Maymo, X. Elias, L. T. Vuong and J. Martorell, Solar Energy Mater. Solar Cells, 95, 735 (2011).

A. A. Al-Ghamdi, W. E. Mahmoud, S. J. Yaghmour and F. M. Al-Marzouki, J. Alloys Compd., 486, 9 (2009).

Z. Zhu, Y. Bai, T. Zhang, Z. Liu, X. Long, Z. Wei, Z. Wang, L. Zhang, J. Wang, F. Yan and S. Yang, Angew. Chem., 126, 12779 (2014).

K. O. Ukoba, A. C. Eloka-Eboka and F. L. Inambao, Renew. Sust. Energy Rev., 82, 2900 (2018).

J. H. Kim, H. M. Lee, D. W. Kang, K. M. Lee and C. K. Kim, Korean J. Chem. Eng., 33, 9, 2711 (2016).

D. Barreca and C. Massignan, Chem. Mater., 13(2), 588 (2001).

P. Yang, X. Tong, G. Wang, Z. Gao, X. Guo and Y. Qin, ACS Appl. Mater. Interfaces, 7, 4772 (2015).

G. Wang, X. Peng, L. Yu, G. Wan, S. Lin and Y. Qin, J. Mater. Chem. A, 3, 2734 (2015).

D. H. Kim, Y. J. Kim, Y. S. Song, B. T. Lee, J. H. Kim, S. Suh and R. Gordon, J. Electrochem. Soc., 150(10), C740 (2003).

T. S. Yang, W. Cho, M. Kim, K. S. An, T. M. Chung, C. G. Kim and Y. Kim, J. Vac. Sci. Technol., A, 23(4), 1238 (2005).

E. Lindahl, M. Ottosson and J. O. Carlsson, Chem. Vap. Deposition, 15, 186 (2009).

L. Yu, G. Wang, G. Wan, G. Wang, S. Lin, X. Li, K. Wang, Z. Bai and Y. Xiang, Dalton Trans., 45, 13779 (2016).

G. Wang, X. Peng, L. Yu, G. Wan, S. Lin and Y. Qin, J. Mater. Chem. A, 3, 2734 (2015).

H. L. Lu, G. Scarel, C. Wiemer, M. Perego, S. Spiga, M. Fanciulli and G. Pavia, J. Electrochem. Soc., 155(10), H807 (2008).

H. L. Lu, G. Scarel, X. L. Li and M. Fanciulli, J. Cryst. Growth, 310, 5464 (2008).

M. K. S. Barr, L. Assaud, Y. Wu, C. Laffon, P. Parent, J, Bachmann and L. Santinacci, Electrochim. Acta, 179, 504 (2015).

P. Motamedi, K. Bosnick, K. Cui, K. Cadien and J. D. Hogan, ACS Appl. Mater. Interfaces, 9, 24722 (2017).

Y. W. Kim and D. H. Kim, Korean J. Chem. Eng., 29(7), 969 (2012).

A. G. Hufnagel, A. K. Henß, R. Hoffmann, O. E. O. Zeman, S. Häringer, D. F. Rohlfing and T. Bein, Adv. Mater. Interfaces, 5, 1701531 (2018).

D. Malwala and P. Gopinath, Environ. Sci.: Nano, 2, 78 (2015).

R. K. Ramachandran, J. Dendooven and C. Detavernier, J. Mater. Chem. A, 2, 10662 (2014).

J. H. Lee and J. H. Moon, Korean J. Chem. Eng., 34(12), 3195 (2017).

N. R. Chodankar, S. H. Ji and D. H. Kim, J. Taiwan Inst. Chem. Eng., 80, 503 (2017).

M. Zafar, J. Y. Yun and D. H. Kim, Korean J. Chem. Eng., 35(2), 567 (2018).

X. Chen, E. Pomerantseva, P. Banerjee, K. Gregorczyk, R. Ghodssi and G. Rubloff, Chem. Mater., 24, 1255 (2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ji, SH., Jang, WS., Son, JW. et al. Characteristics of NiO films prepared by atomic layer deposition using bis(ethylcyclopentadienyl)-Ni and O2 plasma. Korean J. Chem. Eng. 35, 2474–2479 (2018). https://doi.org/10.1007/s11814-018-0179-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-018-0179-5