Abstract

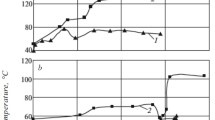

The dehydrogenation and dewaxing of hydrocarbons of middle-distillate fractions, which proceed in the hydrogen medium, are of great importance in the petrochemical and oil refining industries. They increase oil refining depth and allow producing gasoline, kerosene, and diesel fractions used in the production of hydrocarbon fuels, polymer materials, synthetic detergents, rubbers, etc. Herewith, in the process of dehydrogenation of hydrocarbons of middle distillate fractions (C9–C14) hydrogen is formed in the reactions between hydrocarbons, and the excess of hydrogen slows the target reaction of olefin formation and causes the shift of thermodynamic equilibrium to the initial substances. Meanwhile, in the process of hydrodewaxing of hydrocarbons of middle distillate fractions (C5–C27), conversely, hydrogen is a required reagent in the target reaction of hydrocracking of long-chain paraffins, which ensures required feedstock conversion for production of low-freezing diesel fuels. Therefore, in this study we suggest the approach of intensification of the processes of dehydrogenation and dewaxing of middle distillate fractions by means of redistribution of hydrogen between the two units on the base of the influence of hydrogen on the hydrocarbon transformations using mathematical models. In this study we found that with increasing the temperature from 470 °C to 490 °C and decreasing the hydrogen/feedstock molar ratio in the range of 8.5/1.0 to 6.0/1.0 in the dehydrogenation reactor, the production of olefins increased by 1.45–1.55%wt, which makes it possible to reduce hydrogen consumption by 25,000 Nm3/h. Involvement of this additionally available hydrogen in the amount from 10,000 to 50,000 Nm3/h in the dewaxing reactor allows increasing the depth of hydrocracking of long-chain paraffins of middle distillate fractions, and, consequently improving low-temperature properties of produced diesel fraction. In such a way cloud temperature and freezing temperature of produced diesel fraction decrease by 1–4 °C and 10–25 °C (at the temperature of 300 °C and 340 °C respectively). However, when the molar ratio hydrogen/hydrocarbons decreases from 8.5/1.0 to 6.0/1.0 the yield of side products in the dehydrogenation reactor increases: the yield of diolefins increases by 0.1–0.15%wt, the yield of coke increases by 0.07–0.18%wt depending on the feedstock composition, which is due to decrease in the content of hydrogen, which hydrogenates intermediate products of condensation (the coke of amorphous structure). This effect can be compensated by additional water supply in the dehydrogenation reactor, which oxidizes the intermediate products of condensation, preventing catalyst deactivation by coke. The calculations with the use of the model showed that at the supply of water by increasing portions simultaneously with temperature rise, the content of coke on the catalyst by the end of the production cycle comprises 1.25–1.56%wt depending on the feedstock composition, which is by 0.3–0.6%wt lower that in the regime without water supply.

Similar content being viewed by others

References

J. G. Speight, The Refinery of the Future, Elsevier (2011).

D. Stratiev and K. Petkov, Hydrocarbon Process., 88(9), 93 (2009).

G. Phillips and F. Liu, Hydrocarbon Eng., 8(9), 63 (2003).

M. S. Rana, V. Sámano, J. Ancheyta and J. A. I. Diaz, Fuel, 86(9), 1216 (2007).

P. Leprince, Petroleum refining. Volume 3. Conversion Processes, Editions Technip (2000).

D. S. J. Jones and P.R. Pujado, Handbook of Petroleum Processing, Springer (2006).

M. R. Riazi, Characterization and Properties of Petroleum Fractions, ASTM manual series (2005).

J. Ancheyta, A. Alvarez-Majmutov and C. Leyva, Hydrotreating of oil fractions: Multiphase Catalytic Reactors: Theory, Design, Manufacturing, and Applications, John Wiley & Sons, Inc, New Jersey, Canada (2016).

I. Sharafutdinov, D. Stratiev, I. Shishkova, R. Dinkov, A. Batcharov, P. Petkov and N. Rudnev, Fuel, 96, 556 (2012).

A. L. Lown, L. Peerboom, S. Mueller, J. Anderson, D. Miller and C. Lira, Fuel, 117, 544 (2014).

A. Anwar and A. Garforth, Fuel, 173, 189 (2016).

S. V. Lysenko, A. B. Kulikov, M. I. Onishchenko, E. V. Rakhmanov and E. A. Karakhanov, Moscow Univ. Chem. Bull. (Engl. Transl.), 71(1), 37 (2016).

T.-T. Bao, B. Zhou, J. Deng and Z.-J Wu, J. Shanghai Jiaotong University (Science), 19(6), 721 (2014).

J. G. Speight, Hydrogen in Refineries Hydrogen Science and Engineering: Materials, Processes, Systems and Technology (Book Chapter), CRC Press (2016).

L. C. Castañeda, A. D. Muñoz and J. Ancheyta, Catal. Today, 220-222, 248 (2014).

R. Long, K. Picioccio and A. Zagoria, Petroleum Technology Quarterly, 16(3) (2011).

F. E. Cruz and Jr. S. De Oliveira, Int. J. Thermodyn., 11(4), 187 (2008).

J. Docekal, Int. J. Hydrogen Energy, 11(11), 709 (1986).

L. C. Castañeda, J. A. D. Muñoz and J. Ancheyta, Fuel, 90(12), 3593 (2011).

X. Jie, S. Gonzalez-Cortes, T. Xiao, J. Wang, B. Yao, D. R. Slocombe, H. A. Al-Megren, J. R. Dilworth, J. M. Thomas and P. P. Edwards, Angew. Chem., Int. Ed., 56(34), 10170 (2017).

L. Wu, X. Liang, L. Kang and Y. Liu, Chin. J. Chem. Eng., 25(8), 1061 (2017).

S. Sadighi, A. Ahmad and M. Rashidzadeh, Korean J. Chem. Eng., 27(4), 1099 (2010).

G. Zahedi, H. Yaqubi and M. Ba-Shammakh, Appl. Catal., A, 358, 1 (2009).

R. Hayati, S. Z. Abghari, S. Sadighi and M. Bayat, Korean J. Chem. Eng., 32(4), 629 (2015).

J. J. Verstraete, K. Le Lannic and I. Guibard, Chem. Eng. Sci., 62(18–20), 5402 (2007).

A. Alvarez and J. Ancheyta, Appl. Catal., A, 351(2), 148 (2008).

L. Sunggyu, Encyclopedia of Chemical Processing, CRC Press (2005).

G. A. Olah, Hydrocarbon Chemistry, Wiley, New York (2002).

S. B. He. Studies on the catalysts and the coke deposition behavior of the dehydrogenation of long chain paraffins (C 10-C 19 ), Dalian Institute of Chemical Physics, Chinese Academy of Sciences (2009).

D. Sanfilippo and I. Miracca, Catal. Today, 111, 133 (2006).

R. S. París, M. E. L’Abbatea, L. F. Liotta, V. Montes, J. Barrientos, F. Regali, A. Ahoe, M. Boutonnet and S. Järås, Catal. Today, 275, 141 (2016).

R. A. Rakoczy and P. M. Morse, Hydrocarbon Processing, 92(7) (2013).

E. Frantsina, N. Belinskaya and N. Popova, MATEC Web of Conferences, 85, 01023 (2016).

E. V. Frantsina, E. N. Ivashkina, E. D. Ivanchina and R. V. Romanovskii, Chem. Eng. J., 238, 224 (2015).

N. S. Belinskaya, E. V. Frantsina and E. D. Ivanchina, Chem. Eng. J., 329, 283 (2017).

E. N. Ivashkina, E. V. Frantsina, R. V. Romanovsky, I. M. Dolganov, E. D. Ivanchina and A. V. Kravtsov, Catalysis in Industry, 4(2), 110 (2012).

A. V. Kravtsov, E. D. Ivanchina, E. N. Ivashkina, E. V. Frantsina, S. V. Kiseleva and R. V. Romanovskii, Pet. Chem., 53(4), 267 (2013).

N. S. Belinskaya, E. V. Frantsina, E. D. Ivanchina, N. V. Popova and N. E. Belozertseva, Pet. Coal, 58(7), 695 (2016).

N. Chang and Z. Gu, Korean J. Chem. Eng., 31(5), 780 (2014).

S. Yoon, W. C. Choi, Y.-K. Park, H. Y. Kim and C. W. Lee, Korean J. Chem. Eng., 27(1), 62 (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Frantsina, E., Belinskaya, N. & Ivanchina, E. Intensification of the processes of dehydrogenation and dewaxing of middle distillate fractions by redistribution of hydrogen between the units. Korean J. Chem. Eng. 35, 337–347 (2018). https://doi.org/10.1007/s11814-017-0284-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-017-0284-x