Abstract

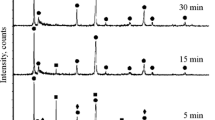

A technique for preparing high purity Li2CO3 powders has been developed through mechanochemical process coupled with the dissolution-filtration process. The first step as mechanochemical reaction of both Na2CO3 and LiCl mixtures was designed to obtain the primary Li2CO3 powders using a ball mill. The second step as the dissolution- filtration process was performed to obtain high purity Li2CO3 powders. Experimental results indicate that the three parameters of milling time, rotation speed, and ball-to-sample mass ratio can closely relate with purity of primary Li2CO3 powders. The XRD patterns of primary Li2CO3 powders indicate that mechanochemical reaction of both Na2CO3 and LiCl can be completed in 15 min under optimal conditions at rotation speed as 600 rpm, ball-to-sample mass ratio as 5/1, and molar ratio of Na2CO3 to LiCl as 1/2. The target products of Li2CO3 powders contain impurity of Na+ less than 0.1 mass% with the minimum values as 0.073 mass%. Two shapes of massive particles and smaller grains less than 1 μm in nano scale can be observed in the target products of Li2CO3 powders.

Similar content being viewed by others

References

R. Mohan and A. S. Myerson, Chem. Eng. Sci., 57, 4277 (2002).

J.W. Mullin, Crystallization (4th Ed.), Butterworth-Heinemann, Oxford, London, UK (2001).

Y. Wang, Z. B. Li and G. P. Demopoulos, J. Cryst. Growth, 310, 1220 (2008).

L. Kourkova and G. Sadovska, Thermochim. Acta, 452, 80 (2007).

E. F. Randall and F. S. Messiha, Brain Res. Bull., 11, 219 (1983).

W.T. Yi, C.Y. Yan and P. H. Ma, Desalin., 249, 729 (2009).

W.T. Yi, C.Y. Yan, P. H. Ma, F.Q. Li and X.M. Wen, Sep. Purif. Technol., 56, 241 (2007).

X. Gu and R. J. Hand, J. Eur. Ceram. Soc., 16, 929 (1996).

W.T. Yi, C.Y. Yan and P. H. Ma, J. Cryst. Growth, 312, 2345 (2010).

J. Jandová, P. Dvořák and N.V. Hong, Hydrometallurgy, 103, 12 (2010).

P.M. Brown, US Patent, 4,036,713 (1977).

P.M. Brown and C. E. Falletta, US Patent, 4,207,297 (1980).

L. H. Parker, J. Chem. Soc. Trans., 105, 1504 (1914).

P. Baláž, A. Alácová, M. Achimovicová, J. Ficeriová and E. Godocíková, J. Cheminformatics, 37, 9 (2006).

S.L. James, C. J. Adams, C. Bolm, D. Braga, P. Collier, T. Frišcic, F. Grepioni, K.D. M. Harris, G. Hyett, W. Jones, A. Krebs, J. Mack, L. Maini, A.G. Orpen, I.P. Parkin, W.C. Shearouse, J.W. Steed and D. C. Waddell, Chem. Soc. Rev., 41, 413 (2012).

G.A. Bowmaker, Chem. Commun., 49, 334 (2013).

C. Xu, S. De, A. M. Balu, M. Ojeda and R. Luque, J. Cheminformatics, 51, 6698 (2015).

P. Pourghahramani and E. Forsberg, Int. J. Miner. Process., 82, 96 (2007).

Author information

Authors and Affiliations

Corresponding author

Additional information

The authors declare no competing financial interest.

Rights and permissions

About this article

Cite this article

Chen, N., Zhou, E., Duan, Dp. et al. Mechanochemistry synthesis of high purity lithium carbonate. Korean J. Chem. Eng. 34, 2748–2755 (2017). https://doi.org/10.1007/s11814-017-0172-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-017-0172-4