Abstract

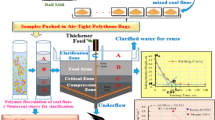

The objective of solid-liquid separation in thickeners in coal preparation plants is to obtain both a clear supernatant liquid with a low turbidity for reuse and a dense slurry. It is important for the smooth operation of the plant to produce good-quality recirculation water. In this study, settling characteristics of coal tailings (d80=70 μm) taken from the thickener feed of Derekoy Coal Preparation Plant (Manisa, Turkey) were investigated with the use of anionic polymers. In the tests we determined the effects of the process parameters including polymer type, polymer dosage, temperature, suspension pH, and pulp density on the flocculation of the fine tailings of the coal preparation operation. Minefloc anionic polymer showed a better flocculation performance in comparison with other polymers. An optimum settling rate of 300 mm/min was reached at a dosage of 30 g/t-solids, a pulp density of 5%, pH 7.9, and temperature 25 °C using Minefloc polymer.

Similar content being viewed by others

References

I. Bentli, Ekoloji, 19, 71 (2010).

P. Mpofu, J.A. Mensah and J. Ralston, Int. J. Min. Proc., 75, 155 (2005).

L. Svarovsky, Characterization of particles suspended in liquids, Solid-liquid separation, London: Butterworth & Co. (Publishers) Ltd. (1981)

B. Oteyaka, A. Yamik, A. Ucar, O. Sahbaz and B. Yilmaz, Proceedings of 19th Int. Mining Cong. and Exhibition of Turkey, 297 (2005).

R. Hogg, Int. J. Min. Proc., 58, 223 (2000).

P. Mpofu, J.A. Mensah and J. Ralston, Int. J. Min. Proc., 71, 247 (2003).

M. Sarioglu, Y. Cebeci and N. Beyazit, Asian J. Chem., 14, 388 (2002).

R. Sivamohan, Int. J. Min. Proc., 28, 247 (1990).

P. Somasundaran and K.K. Das, Flocculation and selective flocculation - an overview, Innovation in Mineral and Coal Processing, A.A. Balkema Publishers, Rotterdam, Netherlands (1998).

B. Ersoy, Proceedings of Turkish 4th Marble Symposium, 449 (2003).

W.C. Foshee, M. J. Swan and R. R. Klimpel, Min. Eng., 293 (1982).

G.G. Maher, J. Env. Sci., 26, 29 (1983).

V.B. Menon, M.C. Woods, M. E. Mullins and L.D. Michaels, Min. Metall. Proc., 4, 193 (1987).

Y.A. Attia and S. Yu, Sep. Sci. Technol., 26, 803 (1991).

Th. F. Tadros, P. Taylor and G. Bognolo, Langmuir, 11, 4678 (1995).

U. Akdemir, S. Aydogan, M. Canbazoglu and A. Ozkan, Proceedings of 16th Mining Congress of Turkey, 411 (1999).

D. Tao, J. G. Groppo and B. K. Parekh, Min. Eng., 2, 163 (2000).

E. Sabah and I. Cengiz, Proceedings of the 14th Turkish Coal Congress, 133 (2004).

E. Sabah and Z. E. Erkan, Fuel, 85, 350 (2006).

N. Alam, O. Ozdemir, M. A. Hampton and A.V. Nguyen, Fuel, 90, 26 (2001).

P. Ofori, A.V. Nguyen, B. Firth, M. Clint and O. Ozdemir, Chem. Eng. J., 172, 914 (2011).

P. Ofori, A.V. Nguyen, B. Firth, C. McNally and M. A. Hampton, Fuel, 97, 262 (2012).

Y. Ji, Q. Lu, Q. Liu and H. Zeng, Coll. Surf., A: Physicochem. Eng. Asp., 430, 29 (2013).

B. Das, S. Prakash, S. K. Biswal and P. S.R. Reddy, J. South. Afr. Inst. Min. and Metall., 106, 707 (2006).

S. Kumar, S. Bhattacharya and N.R. Mandre, J. South. Afr. Inst. Min. and Metall., 114, 945 (2014).

I. Cengiz, E. Sabah and Z. E. Erkan, Madencilik, 43, 15 (2004).

J. Gregory, Crit. Rev. Env. Cont., 19, 185 (1989).

B. Yarar, US. Department of Commerce, National Technical Information Service, Springfield, Scientific Report, 34 (2001).

G. Atesok Madencilik, 26, 15 (1987).

J. Gregory, J. Colloid Interface Sci., 42, 448 (1973).

B. Oner, MSc Thesis, Selcuk University, Turkey (2011).

S.R. Pandey, Int. J. Eng. Res. Technol., 2, 351 (2013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ciftci, H., Isık, S. Settling characteristics of coal preparation plant fine tailings using anionic polymers. Korean J. Chem. Eng. 34, 2211–2217 (2017). https://doi.org/10.1007/s11814-017-0123-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-017-0123-0