Abstract

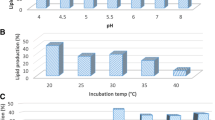

Lipase was produced by Penicillium camembertii KCCM 11268 under solid state fermentation (SSF), and the production process was optimized by using statistical experimental designs. The initial moisture content, cultivation time, inoculum size and concentration of basal medium were considered as the factors of optimum conditions for SSF. P. Camembertii KCCM 11268 was cultivated in SSF using wheat bran as the substrate for lipase production. Under the optimized condition, lipase activity was reached around 7.8 U/ml after eight days fermentation. To partially purify the lipase, ammonium sulfate (80% saturation) was added to the crude lipase solution and concentrated using a diafiltration (VIVAFLOW 50). The concentrated lipase solution from P. Camembertii KCCM 11268 (PCL) was immobilized on silica gel by cross-linking method. Also, PCL was mixed with a commercial lipase solution from Candida rugosa (CRL), and this mixture was co-immobilized on silica gel. The immobilized and co-immobilized lipase activities were 1150.1 and 7924.8 U/g matrix, respectively. Palm oil and methanol were used as substrates and 1mmol of methanol was added every 1.5 h and 2 times during biodiesel production. The reaction was carried out at temperatures of 30, 40, 50, 60 and 70 °C. The maximum biodiesel conversion by co-immobilized lipase was 99% after 5 h at 50 °C.

Similar content being viewed by others

References

R.G. S. Couto and A. M. Sanroma, J. Food Eng., 76, 291 (2006).

M. Raimbault, Electron J. Biotechnol., 1, 234 (1998).

N. Pérez-Guerra, A. Torrado-Agrasar, C. López-Macias and L. Pastrana, Agric. Food Chem., 2, 343 (2003).

M. Oda, M. Kaieda, S. Mana, H. Yamaji, A. Kondo, E. Izumoto and H. Fukuda, Biochem. Eng. J., 45–51, 23 (2005).

J. H. Lee, S. B. Kim, C. Park, B. Tae, S. O. Han and S.W. Kim, Biochem. Biotehcnol., 365–371, 161 (2010).

D. H. Lee, C. Park, J. M. Yeo and S.W. Kim, J. Ind. Eng. Chem., 777–782, 12 (2006).

A.V. L. Pizarro and E.Y. Park, Process Biochem., 1077–1082, 38 (2003).

C. J. Shieh, H. F. Liao and C. C. Lee, Bioresour. Technol., 103–106, 88 (2003).

Y. Shimada, Y. Watanabe, T. Samukawa, A. Sugihara, H. Noda and H. Fukuda, J. Am. Oil Chem. Soc., 789–793, 76 (1999).

Y. Shimada, Y. Watanabe, A. Sugihara and Y. Tominaga, J. Mol. Catal. B-Enzym., 133–142, 17 (2002).

P.M. Neilsen, J. Brask and L. Fjerbaek, Biotechnol. Bioeng., 692–700, 110 (2008).

D. H. Lee, J. M. Kim, H.Y. Shin and S.W. Kim, Biotechnol. Bioprocess Eng., 522–525, 11 (2006).

A. F. Hsu, K. Jones, T. A. Fogolia and W.M. Marmer, Biotechnol. Appl. Biochem., 181–186, 36 (2002).

S. Shweta, S. Shweta and M. N. Gupta, Energy Fuels., 154–159, 18 (2004).

J. H. Lee, S. B. Kim, C. Park and S.W. Kim, Bioresour. Technol., s66–s70, 101 (2010).

J. H. Lee, S.B. Kim, S.W. Kang, Y. S. Song, C. Park and S.W. Kim, Bioresour. Technol., 2105–2108, 102 (2011).

J. Cordova, M. Nemmaoui, M. Ismaïli-Alaoui, A. Morin, S. Roussos, M. Raimbault and B. Benjilali, J. Mol. Catal. B Enzymatic, 5, 75 (1998).

J. H. Lee, D. H. Lee, J. S. Lim, B. H. Um, C. Park and S.W. Kim, J. Microbiol. Biotechnol., 18, 1927 (2008).

S. B. Kim, J. H. Lee, K. K. Oh, S. J. Lee, J.Y. Lee, J. S. Kim and S.W. Kim, Biotechnol. Biopro. Eng., 16, 725 (2011).

K. Sunitha, J. K. Lee and T. K. Oh, Bioproc. Eng., 21, 477 (1999).

B. H. Um and S. H. Bae, Korean J. Chem. Eng., 28, 1172 (2011).

J. Li, L. Liu, G. Du, J. Chen and W. Tao, Korean J. Chem. Eng., 27, 1233 (2010).

A. Amrane, V. Prstel and Y. Prigent, J. Gen. Appl. Microbiol., 251–5, 49 (2003).

S. F. Torabi, K. Khajeh, S. Ghasempur, N. Ghaemi and S.O. R. Siadat, J. Biotechnol., 111–20, 131 (2007).

R. Gupta, P. Rathi and S. Bradoo, Crit. Rev. Food Sci. Nutr., 635–44, 43 (2003).

H. S. Krishna and G.N. Karanth, Catal. Rev., 499–591, 44 (2002).

J. Lifka and B. Ondruschka, Chem. Eng. Technol., 1156–9, 27 (2004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Malilas, W., Kang, S.W., Kim, S.B. et al. Lipase from Penicillium camembertii KCCM 11268: Optimization of solid state fermentation and application to biodiesel production. Korean J. Chem. Eng. 30, 405–412 (2013). https://doi.org/10.1007/s11814-012-0132-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-012-0132-y