Abstract

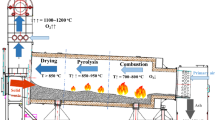

The volatile organic compounds (VOCs) contained in coconut shell are wasted in the carbonization process of coconut shell due to the difficulty of recovery. The VOCs recovery is useful and necessary, because the VOCs are a sustainable energy source, and the recovery is an economically feasible project. A simulation model of the VOC recovery process from coconut shell using a rotary kiln is developed to investigate the process characteristics and the role of model parameters. The model includes the energy and material balances for the processing solid and the gas in the kiln. The validity of the proposed model is partially examined with the experimental results. From the simulation, the dominant heat transfer mechanism is determined for the understanding of the process operation. In addition, the optimal operating conditions of the rotary kiln are found for the use in the design and control of the kiln.

Similar content being viewed by others

References

B. Cagnon, X. Py, A. Guillot and F. Stoeckli, Micropor. Mesopor. Mater., 57, 273 (2003).

O. A. Oritiz, G. I. Suárez and A. Nelson, Comput. Chem. Eng., 29, 1837 (2005).

T. Suzuki, T. Okazaki, K. Yamamoto, H. Nakata and O. Fujita, J. Therm. Sci. Eng., 3, 523 (2008).

T. Suzuki, T. Okazaki, K. Yamamoto, H. Nakata and O. Fujita, J. Therm. Sci. Eng., 3, 532 (2008).

P. Thammavong, M. Debacq, S. Vitu and M. Dupoizat, Chem. Eng. Technol., 34,707 (2011).

F. Patisson, E. Lebas, F. Hanrot, D. Ablitzer and J.-L. Houzelot, Metall. Mater., 31B, 381 (2000).

F. Patisson, E. Lebas, F. Hanrot, D. Ablitzer and J.-L. Houzelot, Metall. Mater., 31B, 391 (2000).

M. J. Antal, Jr. and M. Gronli, Ind. Eng. Chem. Res., 42, 1619 (2003).

F. Cangialosi, F. D. Canio, G. Intini, M. Notarnicola, L. Liberti, G. Belz and P. Caramuscio, Fuel, 85, 2294 (2006).

P. Baggio, M. Baratieri, A. Gasparella and G.A. Longo, Appl. Therm. Eng., 28, 136 (2008).

Y.N. Chun, S.C. Kim and K. Yoshikawa, Appl. Energy, 88, 1105 (2011).

H.-Y. Kang, S.-S. Park and Y.-S. Rim, Korean J. Chem. Eng., 23, 948 (2006).

P. Ji, W. Feng and B. Chen, Ind. Eng. Chem. Res., 48, 3909 (2009).

C. Tangsathithulchai, Y. Ngernyen and M. Tangsathithulchai, Korean J. Chem. Eng., 26, 1341 (2009).

V. F. Olontsev, I. A. Borisova and E.A. Sazonova, Solid Fuel Chem., 45, 44 (2011).

W. L. McCabe, P. Harriott and J. C. Smith, Unit operations of chemical engineering, Mc-Graw-Hill, New York (1992).

Y. H. Kim, Korean J. Chem. Eng., 28, 27 (2011).

S.-W. Rhee, Korean Chem. Eng. Res., 47, 230 (2009).

E. Benanti, C. Freda, V. Lorefice, G. Braccio and K. Sharma, Therm. Sci., 15, 145 (2011).

X. Li, T. Wang, R. T. Tonti and L. Edwards, Proc. 29th Ind. Energy Tech. Conf., New Orleans, USA (2007).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, Y.H. Development of process model of a rotary kiln for volatile organic compound recovery from coconut shell. Korean J. Chem. Eng. 29, 1674–1679 (2012). https://doi.org/10.1007/s11814-012-0104-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-012-0104-2