Abstract

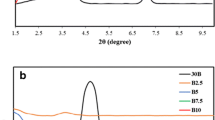

EPDM/organoclay nanocomposites were prepared by a melt mixing of a semicrystalline EPDM grafted with maleic anhydride and an organoclay (Cloisite 20A) in an internal mixer. XRD and TEM analysis revealed that the EPDM/clay forms a partially exfoliated nanocomposite and the silicate layers of the clay are uniformly dispersed at a nanometer scale in the rubber matrix. DSC studies indicated that the clay nanoparticles caused an increase in the nonisothermal crystallization temperature of the EPDM. Tensile and dynamic mechanical analysis showed that a small amount of the clay nanoparticles effectively enhanced the stiffness of the EPDM without adversely affecting its flexibility. The EPDM/clay nanocomposites were used to produce foams by using a batch process in an autoclave, with supercritical carbon dioxide as a foaming agent. The exfoliated nanocomposite produced a microcellular foam with average cell size as small as 6.23 μm and cell density as high as 2.4×1010 cell/cm3.

Similar content being viewed by others

References

T. Lan and T. J. Pinnavaia, Chem. Mater., 6, 2216 (1994).

H. Shi, T. Lan and T. J. Pinnavaia, Chem. Mater., 8, 1584 (1996).

L.A. Utracki, Clay-containing polymeric nanocomposites, Rapra Technology Ltd., Shawbury, UK (2004).

J.W. Cho and D. R. Paul, Polymer, 42, 1083 (2001).

T. D. Fornes, P. J. Yoon, H. Keskkula and D. R. Paul, Polymer, 42, 9929 (2001).

S. R. Lee, H. M. Park, H. Lim, T. Kang, X. Li, W. J. Cho and C. S. Ha, Polymer, 43, 2495 (2002).

Z. Liu, K. Chen and D. Yan, Eur. Polym. J., 39, 2359 (2003).

J. C. Huang, Z. Zhu, J. Yin, X. Qian and Y.Y. Sun, Polymer, 42, 873 (2001).

N. Hasegawa, H. Okamoto, M. Kawasumi and A. Usuki, J. Appl. Polym. Sci., 74, 3359 (1999).

N. Hasegawa, H. Okamoto, M. Kato and A. Usuki, J. Appl. Polym. Sci., 78, 1918 (2000).

N. Hasegawa, H. Okamoto and A. Usuki, J. Appl. Polym. Sci., 93, 758 (2004).

K. H. Wang, M. H. Choi, C. M. Koo, Y. S. Choi and I. J. Chung, Polymer, 42, 9819 (2001).

L. J. Lee, C. Zeng, X. Cao, X. Han, J. Shen and G. Xu, Comp. Sci. Technol., 65, 2344 (2005).

P. S. Chum, C. K. Kao and G.W. Knight, Plast. Eng., June, 21 (1995).

P. H. Nam, P. Maiti, M. Okamoto, T. Kotaka, T. Nakayama, M. Takada, M. Ohshima, A. Usuki, N. Hasegawa and H. Okamoto, Polym. Eng. Sci., 42, 1907 (2002).

K. Taki, T. Yanagimoto, E. Funami, M. Okamoto and M. Ohshima, Polym. Eng. Sci., 44, 1004 (2004).

M. Mitsunaga, Y. Ito, S. S. Ray, M. Okamoto and K. Hironaka, Macromol. Mater. Eng., 288, 543 (2003).

Y. Ito, M. Yamashita and M. Okamoto, Macromol. Mater. Eng., 291, 773 (2006).

Y. Fujimoto, S. S. Ray, M. Okamoto, A. Ogami, K. Yamada and K. Ueda, Macromol. Rapid Commun., 24, 457 (2003).

Y. Di, S. Iannace, E. Di Maio and L. Nicolais, J. Polym. Sci.: Part B: Polym. Phys., 43, 689 (2005).

X. Han, C. Zeng, L. J. Lee, K.W. Koelling and D. L. Tomasko, Polym. Eng. Sci., 43, 1261 (2003).

W. Strauss and N. A. D’souza, J. Cell. Plast., 40, 229 (2004).

C. Zeng, X. Han, L. J. Lee and K.W. Koelling, Adv. Mater., 15, 1743 (2003).

Y.W. Chang, D. S. Lee and S.Y. Bae, Polym. Int., 55, 184 (2006).

R. A. Vaia and E. P. Giannelis, Macromolecules, 30, 8000 (1997).

L. Priya and J. P. Jog, J. Polym. Sci. Part B: Polym. Phys., 41, 31 (2003).

Z. Wang and T. J. Pinnavaia, Chem. Mater., 10, 3769 (1998).

R. Xu, E. Manias, A. J. Snyder and J. Runt, J. Biomed. Mater. Res., 64A, 114 (2003).

T. Amornsakchai, B. Sinpatanapan, S. Bualek-Limcharoen and W. Meesiri, Polymer, 40, 2993 (1999).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, YW., Kim, S., Kang, S.C. et al. Thermomechanical properties of ethylene-propylene-diene terpolymer/organoclay nanocomposites and foam processing in supercritical carbon dioxide. Korean J. Chem. Eng. 28, 1779–1784 (2011). https://doi.org/10.1007/s11814-011-0002-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-011-0002-z