Abstract

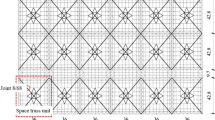

A set of parametric stress analyses was carried out for two-planar tubular DKT-joints under different axial loading conditions. The analysis results were used to present general remarks on the effects of the geometrical parameters on stress concentration factors (SCFs) at the inner saddle, outer saddle, and crown positions on the central brace. Based on results of finite element (FE) analysis and through nonlinear regression analysis, a new set of SCF parametric equations was established for fatigue design purposes. An assessment study of equations was conducted against the experimental data and original SCF database. The satisfaction of acceptance criteria proposed by the UK Department of Energy (UK DoE) was also checked. Results of parametric study showed that highly remarkable differences exist between the SCF values in a multi-planar DKT-joint and the corresponding SCFs in an equivalent uni-planar KT-joint having the same geometrical properties. It can be clearly concluded from this observation that using the equations proposed for uni-planar KT-connections to compute the SCFs in multi-planar DKT-joints will lead to either considerably under-predicting or over-predicting results. Hence, it is necessary to develop SCF formulae specially designed for multi-planar DKT-joints. Good results of equation assessment according to UK DoE acceptance criteria, high values of correlation coefficients, and the satisfactory agreement between the predictions of the proposed equations and the experimental data guarantee the accuracy of the equations. Therefore, the developed equations can be reliably used for fatigue design of offshore structures.

Similar content being viewed by others

References

Ahmadi H, Lotfollahi-Yaghin MA, Aminfar MH (2011). Geometrical effect on SCF distribution in uni-planar tubular DKT-joints under axial loads. Journal of Constructional Steel Research, 67(8), 1282–1291.

Ahmadi H, Lotfollahi-Yaghin MA (2008). Geometrical effect on the stress distribution along the weld toe for tubular KT-joints under balanced axial loading. Proceeding of the 8th International Conference on Coasts, Ports and Marine Structures (ICOPMAS), Tehran, Iran.

Chang E, Dover WD (1999). Parametric equations to predict stress distributions along the intersection of tubular X and DT-joints. International Journal of Fatigue, 21(6), 619–635.

Chiew SP, Gupta A, Wu NW (2001). Neural network-based estimation of stress concentration factors for steel multiplanar tubular XT-joints. Journal of Constructional Steel Research, 57(2), 97–112.

Chiew SP, Soh CK, Fung TC, Soh AK (1999). Numerical study of multiplanar tubular DX-joints subject to axial loads. Computers & Structures, 72(6), 746–761.

Chiew SP, Soh CK, Wu NW (2000). General SCF design equations for steel multiplanar tubular XX-joints. International Journal of Fatigue, 22(4), 283–293.

Department of Energy (1983). Background notes to the fatigue guidance of offshore tubular joints. HMSO, London, UK.

Efthymiou M (1988). Development of SCF formulae and generalized influence functions for use in fatigue analysis. Offshore Tubular Joints Conference, Surrey, UK.

Efthymiou M, Durkin S (1985). Stress concentrations in T/Y and gap/overlap K-joints. Proceedings of the Conference on Behavior of Offshore Structures, Delft, Netherlands, 429–440.

Gao F (2006). Stress and strain concentrations of completely overlapped tubular joints under lap brace OPB load. Thin-Walled Structures, 44(8), 861–871.

Gao F, Shao YB, Gho WM (2007). Stress and strain concentration factors of completely overlapped tubular joints under lap brace IPB load. Journal of Constructional Steel Research, 63(3), 305–316.

Gho WM, Gao F (2004). Parametric equations for stress concentration factors in completely overlapped tubular K (N)-joints. Journal of Constructional Steel Research, 60(12), 1761–1782.

Hellier AK, Connolly MP, Dover WD (1990). Stress concentration factors for tubular Y- and T-joints. International Journal of Fatigue, 12(1), 13–23.

IIW-XV-E (1999). Recommended fatigue design procedure for welded hollow section joints. IIW Docs, XV-1035-99/XIII-1804-99, International Institute of Welding, Paris, France.

Karamanos SA, Romeijn A, Wardenier J (1999). Stress concentrations in multi-planar welded CHS XX-connections. Journal of Constructional Steel Research, 50(3), 259–282.

Karamanos SA, Romeijn A, Wardenier J (2002). SCF equations in multi-planar welded tubular DT-joints including bending effects. Marine Structures, 15(2), 157–173.

Karamanos SA, Romeijn A, Wardenier J (2002). Stress concentrations in tubular gap K-joints: mechanics and fatigue design. Engineering Structures, 22(1), 4–14.

Kuang JG, Potvin AB, Leick RD (1975). Stress concentration in tubular joints. Offshore Technology Conference, Houston, Texas, USA, Paper OTC 2205.

Lee MMK (1999). Strength, stress and fracture analyses of offshore tubular joints using finite elements. Journal of Constructional Steel Research, 51(3), 265–286.

Lie ST, Lee CK, Chiew SP, Shao YB (2005). Mesh modelling and analysis of cracked uni-planar tubular K-joints. Journal of Constructional Steel Research, 61(2), 235–265.

Lie ST, Lee CK, Wong SM (2001). Modeling and mesh generation of weld profile in tubular Y-joint. Journal of Constructional Steel Research, 57(5), 547–567.

Liu X, Feng G, Ren H (2006). Study on the application of spectral fatigue analysis. Journal of Marine Science and Application, 5(2), 42–46.

Lotfollahi-Yaghin MA, Ahmadi H (2009). Numerical parametric study of stress concentration along the intersection of tubular KT-joints subjected to balanced axial loading. Proceedings of the 19th International Offshore and Polar Engineering Conference (ISOPE), Osaka, Japan.

Lotfollahi-Yaghin MA, Ahmadi H (2010). Effect of geometrical parameters on SCF distribution along the weld toe of tubular KT-joints under balanced axial loads. International Journal of Fatigue, 32(4), 703–719.

Morgan MR, Lee MMK (1998). Prediction of stress concentrations and degrees of bending in axially loaded tubular K-joints. Journal of Constructional Steel Research, 45(1), 67–97.

Morgan MR, Lee MMK (1998). Parametric equations for distributions of stress concentration factors in tubular K-joints under out-of-plane moment loading. International Journal of Fatigue, 20(6), 449–461.

N’Diaye A, Hariri S, Pluvinage G, Azari Z (2007). Stress concentration factor analysis for notched welded tubular T-joints. International Journal of Fatigue, 29, 1554–1570.

N’Diaye A, Hariri S, Pluvinage G, Azari Z (2009). Stress concentration factor analysis for welded, notched tubular T-joints under combined axial, bending and dynamic loading. International Journal of Fatigue, 31(2), 367–374.

Shao YB (2004). Proposed equations of stress concentration factor (SCF) for gap tubular K-joints subjected to bending load. International Journal of Space Structures, 19, 137–147.

Shao YB, Du ZF, Lie ST (2009). Prediction of hot spot stress distribution for tubular K-joints under basic loadings. Journal of Constructional Steel Research, 65(10–11), 2011–2026.

Smedley P, Fisher P (1991). Stress concentration factors for simple tubular joints. Proceedings of the International Offshore and Polar Engineering Conference, Edinburgh, Scotland.

UK Health and Safety Executive (1992). Stress concentration factors for tubular complex joints. OTH 91 353, Lloyd’s Register of Shipping, UK.

UK Health and Safety Executive (1997). Stress concentration factors for simple tubular joints-assessment of existing and development of new parametric formulae. OTH 354, Lloyd’s Register of Shipping, London, UK.

Wingerde AM, Packer JA, Wardenier J (2001). Simplified SCF formulae and graphs for CHS and RHS K- and KK-connections. Journal of Constructional Steel Research, 57(3), 221–252.

Woghiren CO, Brennan FP (2009). Weld toe stress concentrations in multi planar stiffened tubular KK Joints. International Journal of Fatigue, 31(1), 164–172.

Wordsworth AC (1981). Stress concentration factors at K and KT tubular joint. Proceedings of the Conference on Fatigue of Offshore Structural Steels, London, UK, 59–69.

Wordsworth AC, Smedley GP (1978). Stress concentrations at unstiffened tubular joints. Proceedings of the European Offshore Steels Research Seminar, Cambridge, UK, Paper 31.

Zhao XL, Herion S, Packer JA, Puthli R, Sedlacek G, Wardenier J (2000). Design guide for circular and rectangular hollow section joints under fatigue loading. CIDECT Publication, No.8, TUV Verlag, Germany.

Author information

Authors and Affiliations

Corresponding author

Additional information

Hamid Ahmadi was born in 1984. He got a BSc degree in civil engineering and an MSc degree in offshore structures engineering from the University of Tabriz, Iran. He is a PhD candidate in the Faculty of Civil Engineering at the University of Tabriz. He has authored over 30 technical papers and reports, as well as a book on dynamics of offshore structures. His current research includes the fatigue analysis and design of tubular joints, dynamics of offshore structures, and the structural reliability.

Mohammad Ali Lotfollahi-Yaghin was born in 1958. He got a BSc degree in civil engineering from the Isfahan University of Technology, Iran, an MSc degree in structural engineering from the University of Tabriz, Iran, and a PhD degree in offshore structures engineering from Heriot-Watt University, UK. He is working as an associate professor in the Faculty of Civil Engineering at the University of Tabriz. His current research interests include dynamics of offshore structures and reinforced concrete structures. He has authored over 100 technical papers and reports, as well as 2 books on FE analysis and dynamics of offshore structures.

Rights and permissions

About this article

Cite this article

Ahmadi, H., Lotfollahi-Yaghin, M.A. & Aminfar, M.H. Stress concentration factors at saddle and crown positions on the central brace of two-planar welded CHS DKT-connections. J. Marine. Sci. Appl. 11, 83–97 (2012). https://doi.org/10.1007/s11804-012-1109-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11804-012-1109-2