Abstract

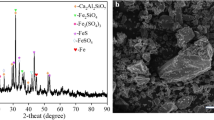

Due to the high toxicity of cyanide, researchers are trying to find an environmentally friendly and sustainable leaching process for precious metals. Thiosulfate is considered one of the most promising alternative leaching systems. Nevertheless, a traditional thiosulfate leaching solution generally consists of copper sulfate and ammonia, in which copper sulfate acts as oxidant and ammonia acts as copper ion stabilizer. However, ammonia is another toxic reagent. For this reason, a novel and eco-friendly system of copper sulfate-tartrate-thiosulfate was investigated for silver sulfide leaching in this work. The effects of rotation speed, temperature, initial pH, copper sulfate, tartrate and thiosulfate concentrations and different atmospheres on the dissolution rate of Ag2S were examined. The process of silver sulfide dissolution is controlled by chemical reactions with an apparent activation energy of 43.49 kJ/mol. The reaction orders of silver sulfide leaching with respect to copper sulfate, tartrate, and thiosulfate concentrations in copper sulfate-tartrate-thiosulfate solutions are 0.491, 1.366, and 0.916, respectively. A detailed dissolution route of Ag2S was proposed based on XRD analysis of intermediate products such as Ag3CuS2, AgCuS and (Ag, Cu)2S. XPS analysis indicated that elemental sulfur was determined to be the final oxidant product of sulfur ions from Ag2S.

摘要

由于氰化物具有高毒性, 研究人员正在寻找一种环境友好和可持续的贵金属浸出工艺。硫代硫酸盐被认为是最有前途的替代浸出体系之一。传统的硫代硫酸盐浸出液一般由硫酸铜和氨组成, 其中硫酸铜作为氧化剂, 氨作为铜离子稳定剂。然而, 氨也是有毒试剂。为此, 本文研究了一种新型的、环保的硫酸铜-酒石酸盐-硫代硫酸盐体系用于硫化银的浸出, 并考察了转速、温度、初始pH 值、硫酸铜、酒石酸盐和硫代硫酸盐浓度以及不同气氛对硫化银溶解速率的影响。在硫酸铜-酒石酸盐-硫代硫酸盐溶液中, 硫化银的溶解过程受化学反应控制, 其表观活化能为43.49 kJ/mol。硫化银浸出的反应级数与硫酸铜、酒石酸盐和硫代硫酸盐浓度的关系分别为0.491、1.366 和0.916。对比Ag 2 S 浸出前、后的XRD 分析结果, 提出了Ag2S在硫酸铜-酒石酸盐-硫代硫酸盐溶液中可能的溶解路线, 即Ag2S 被Cu(I)-S2O 2−3 逐步取代, 生成中间产物Ag3CuS2 、AgCuS 和(Ag, Cu)2S, 最终以Ag(S2O3) 3−2 的形式进入溶液。XPS 分析结果表明单质S 是Ag2S中硫离子的最终氧化产物。

Similar content being viewed by others

References

CHEN Jun-nan, XIE Feng, WANG Wei, et al. Leaching of gold and silver from a complex sulfide concentrate in copper-tartrate-thiosulfate solutions [J]. Metals, 2022, 12(7): 1152. DOI: https://doi.org/10.3390/met12071152.

LARRABURE G, RODRIGUEZ-REYES J C F. A review on the negative impact of different elements during cyanidation of gold and silver from refractory ores and strategies to optimize the leaching process [J]. Minerals Engineering, 2021, 173: 107194. DOI: https://doi.org/10.1016/j.mineng.2021.107194.

DESCHÊNES G. Advances in the cyanidation of gold [M]//Gold Ore Processing. Amsterdam: Elsevier, 2016: 429–445. DOI: https://doi.org/10.1016/b978-0-444-63658-4.00026-8.

GUI Qi-hao, HU Yu-ting, WANG Shi-xing, et al. Mechanism of synergistic pretreatment with ultrasound and ozone to improve gold and silver leaching percentage [J]. Applied Surface Science, 2022, 576: 151726. DOI: https://doi.org/10.1016/j.apsusc.2021.151726.

UMETSU Y, LI Z, BUSTOS R C, et al. Leaching of silver sulfide in weakly acidic thiourea solutions [J]. Bulletin of the Research Institute of Mineral Dressing & Metallurgy Tohoku University, 1991, 47: 58–65.

DUTRIZAC J E. The leaching of silver sulphide in ferric ion media [J]. Hydrometallurgy, 1994, 35(3): 275–292. DOI: https://doi.org/10.1016/0304-386X(94)90056-6.

HOLLOWAY P C, MERRIAM K P, ETSELL T H. Nitric acid leaching of silver sulphide precipitates [J]. Hydrometallurgy, 2004, 74(3–4): 213–220. DOI: https://doi.org/10.1016/j.hydromet.2004.05.003.

XIE Feng, DREISINGER D B. Leaching of silver sulfide with ferricyanide-cyanide solution [J]. Hydrometallurgy, 2007, 88(1–4): 98–108. DOI: https://doi.org/10.1016/j.hydromet.2007.03.008.

LUNA R M, LAPIDUS G T. Cyanidation kinetics of silver sulfide [J]. Hydrometallurgy, 2000, 56(2): 171–188. DOI: https://doi.org/10.1016/S0304-386X(00)00072-4.

XIE Feng, CHEN Jun-nan, WANG Jian, et al. Review of gold leaching in thiosulfate-based solutions [J]. Transactions of Nonferrous Metals Society of China, 2021, 31(11): 3506–3529. DOI: https://doi.org/10.1016/S1003-6326(21)65745-X.

CUI Yi-qi, TONG Xiong, LOPEZ-VALDIVIESO A. Silver sulfide leaching with a copper-thiosulfate solution in the absence of ammonia [J]. Rare Metals, 2011, 30(2): 105–109. DOI: https://doi.org/10.1007/s12598-011-0206-8.

DEUTSCH J L, DREISINGER D B. Silver sulfide leaching with thiosulfate in the presence of additives. Part I: Copper-ammonia leaching [J]. Hydrometallurgy, 2013, 137: 156–164. DOI: https://doi.org/10.1016/j.hydromet.2013.03.012.

PUENTE-SILLER D M, FUENTES-ACEITUNO J C, NAVA-ALONSO F. Study of thiosulfate leaching of silver sulfide in the presence of EDTA and sodium citrate. Effect of NaOH and NH4OH [J]. Hydrometallurgy, 2014, 149: 1–11. DOI: https://doi.org/10.1016/j.hydromet.2014.06.004.

PUENTE-SILLER D M, FUENTES-ACEITUNO J C, NAVA-ALONSO F, et al. A phenomenological study of the silver sulfide passivation and oxidative degradation of thiosulfate in the thiosulfate-ammonia-copper-citrate leaching system [J]. Hydrometallurgy, 2021, 200: 105547. DOI: https://doi.org/10.1016/j.hydromet.2020.105547.

BANIJAMALI S H, RAYGAN S, ALI AMADEH A. Leaching behavior of silver sulfide in the sodium thiosulfate-copper sulfate-sodium metabisulfite system [J]. Minerals Engineering, 2021, 174: 107275. DOI: https://doi.org/10.1016/j.mineng.2021.107275.

HADI BANIJAMALI S, RAYGAN S, ALI AMADEH A. Study of silver extraction from Ag2S containing concentrate in the presence of copper sulfate, sodium thiosulfate, sodium metabisulfite, and ascorbic acid [J]. Minerals Engineering, 2022, 183: 107607. DOI: https://doi.org/10.1016/j.mineng.2022.107607.

DEUTSCH J L, DREISINGER D B. Silver sulfide leaching with thiosulfate in the presence of additives. Part II: Ferric complexes and the application to silver sulfide ore [J]. Hydrometallurgy, 2013, 137: 165–172. DOI: https://doi.org/10.1016/j.hydromet.2013.03.013.

XU Bin, YANG Yong-bin, LI Qian, et al. Stage leaching of a complex polymetallic sulfide concentrate: Focus on the extraction of Ag and Au [J]. Hydrometallurgy, 2016, 159: 87–94. DOI: https://doi.org/10.1016/j.hydromet.2015.10.008.

ROINE A. Outokumpu HSC chemistry for windows [M]//Chemical Reaction and Equilibrium Software with Extensive Ther-mochemical Database. Pori, Finland: Outokumpu Research, 1994.

AYLMORE M G, MUIR D M. Thiosulfate leaching of gold—A review [J]. Minerals Engineering, 2001, 14(2): 135–174. DOI: https://doi.org/10.1016/S0892-6875(00)00172-2.

ABBRUZZESE C, FORNARI P, MASSIDDA R, et al. Thiosulphate leaching for gold hydrometallurgy [J]. Hydrometallurgy, 1995, 39(1–3): 265–276. DOI: https://doi.org/10.1016/0304-386X(95)00035-F.

CHEN Jun-nan, XIE Feng, WANG Wei, et al. Leaching of a carbonaceous gold concentrate in copper-tartrate-thiosulfate solutions [J]. Minerals Engineering, 2022, 183: 107605. DOI: https://doi.org/10.1016/j.mineng.2022.107605.

WANG Jian, XIE Feng, PAN Yue, et al. Leaching of gold with copper-citrate-thiosulfate solutions [J]. Mineral Processing and Extractive Metallurgy Review, 2022, 43(7): 916–925. DOI: https://doi.org/10.1080/08827508.2021.1969389.

HÖRNER T G, KLÜFERS P. The species of Fehling’s solution [J]. European Journal of Inorganic Chemistry, 2016, 2016(12): 1798–1807. DOI: https://doi.org/10.1002/ejic.201600168.

CUI Yi-qi. Study on the process and mechanism of ammonia-free thiosulfate leaching of silver sulfide ore [D]. Kunming: Kunming University of Science and Technology, 2009. (in Chinese).

ALVARADO-MACÍAS G, FUENTES-ACEITUNO J C, NAVA-ALONSO F. Study of silver leaching with the thiosulfate-nitrite-copper alternative system: Effect of thiosulfate concentration and leaching temperature [J]. Minerals Engineering, 2016, 86: 140–148. DOI: https://doi.org/10.1016/j.mineng.2015.12.011.

ZHANG Yan, XU Bin, ZHENG Yun-quan, et al. Hexaamminecobalt(III) catalyzed thiosulfate leaching of gold from a concentrate calcine and gold recovery from its pregnant leach solution via resin adsorption [J]. Minerals Engineering, 2021, 171: 107079. DOI: https://doi.org/10.1016/j.mineng.2021.107079.

DESCOSTES M, MERCIER F, BEAUCAIRE C, et al. Nature and distribution of chemical species on oxidized pyrite surface: Complementarity of XPS and nuclear microprobe analysis [J]. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 2001, 181(1–4): 603–609. DOI: https://doi.org/10.1016/S0168-583X(01)00627-9.

BAI Yun-long, WANG Wei, XIE Feng, et al. Effect of temperature, oxygen partial pressure and calcium lignosulphonate on chalcopyrite dissolution in sulfuric acid solution [J]. Transactions of Nonferrous Metals Society of China, 2022, 32(5): 1650–1663. DOI: https://doi.org/10.1016/S1003-6326(22)65900-4.

BUCKLEY A N, WOODS R. Identifying chemisorption in the interaction of thiol collectors with sulfide minerals by XPS: Adsorption of xanthate on silver and silver sulfide [J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 1995, 104(2–3): 295–305. DOI: https://doi.org/10.1016/0927-7757(95)03279-1.

TERZYK A P, RYCHLICKI G. The influence of activated carbon surface chemical composition on the adsorption of acetaminophen (paracetamol) in vitro [J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2000, 163(2–3): 135–150. DOI: https://doi.org/10.1016/s0927-7757(99)00298-8.

Author information

Authors and Affiliations

Corresponding author

Additional information

Contributors

XIE Feng and CHEN Jun-nan provided the concept and edited the draft of the manuscript. CHEN Jun-nan conducted the literature review and wrote the first draft of the manuscript. WANG Wei, FU Yan, WANG Jian and XU Bin edited the draft of the manuscript.

Foundation item

Project(N182502044) supported by the Fundamental Research Funds for Central Universities of China

Conflict of interest

CHEN Jun-nan, XIE Feng, WANG Wei, FU Yan, WANG Jian and XU Bin declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Chen, Jn., Xie, F., Wang, W. et al. Leaching of silver sulfide with copper sulfate-tartrate-thiosulfate solutions. J. Cent. South Univ. 30, 677–690 (2023). https://doi.org/10.1007/s11771-023-5272-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-023-5272-1