Abstract

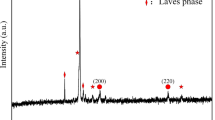

In order to study the corrosion resistance of high-speed laser cladding (HLC) coating while improving production efficiency, a CoCrFeNiMo0.2 high-entropy alloy (HEA) coating was prepared by HLC. The optimized parameters of HLC are laser power of 880 W, scanning speed of 18 m/min, overlapping ratio of 60%, and powder feed speed of 3 r/min. Then, the surface roughness, microstructure, phase composition, element distribution, and electrochemical properties in 3.5 wt% NaCl solution of the coatings were analyzed, respectively. The local surface roughness of the CoCrFeNiMo0.2 HEA coating was found to be 15.53 µm. A distinct metallurgical bond could be observed between the coating and the substrate. Compared to the conventional laser cladding (CLC), the results of electrochemical tests showed that CoCrFeNiMo0.2 HEA coating exhibited a significant passivation. The corrosion current density of 5.4411×10−6 A·cm−2 and the corrosion potential of −0.7445 V for the HLC coating were calculated by the Tafel extrapolation method. The CLC coating’s corrosion current density and corrosion potential are 2.7083×10−5 A·cm−2 and −0.9685 V, respectively. The HLC coating shows a superior corrosion resistance, crucially due to the uniform and fine grains. Under various complex and harsh working conditions, this method can be widely used in the field of repairing and remanufacturing of corrosion-proof workpieces.

摘要

在提高生产效率的同时,获得较强CoCrFeNiMo0.2高熵合金(HEA)的耐蚀性,采用高速激光熔覆 (HLC)技术制备了CoCrFeNiMo0.2 高熵合金涂层。以优化后的HLC工艺参数(激光功率880 W、扫描速 度18 m/min、搭接率60%、送粉速度3 r/min)制备了本文中的涂层。分别对涂层的表面粗糙度、微观 结构、相组成、元素分布进行了分析,并且在3.5 wt% NaCl 溶液中采用三电极体系进行了电化学试 验,对HLC和传统激光熔覆(CLC)的CoCrFeNiMo0.2高熵合金涂层的耐蚀性能进行测试和分析。试验结 果表明: HLC技术制备的CoCrFeNiMo0.2高熵合金涂层的表面粗糙度为15.53 μm,涂层中为单一的FCC 相,在涂层与基体之间通过线扫描能谱分析可以观察到明显的冶金结合,涂层自底部到顶部的微观组 织依次为平面晶、胞状组织、柱状树枝晶和等轴树枝晶。电化学测试结果表明,与CLC 涂层相比, HLC技术制备的CoCrFeNiMo0.2高熵合金涂层表现出明显的钝化效果。采用Tafel 外推法计算了HLC涂 层的自腐蚀电流密度为5.4411×10−6 A·cm−2、自腐蚀电位为−0.7445 V,CLC涂层的自腐蚀电流密度和自 腐蚀电位分别为2.7083×10−5 A·cm−2和−0.9685 V。HLC技术制备的CoCrFeNiMo0.2高熵合金涂层表现出 优越的耐蚀性,主要是由于其表面微观组织为均匀细小的晶粒。HLC技术可推广应用于各种复杂恶劣 的工作条件下的耐腐蚀工件修复以及再制造领域。

Similar content being viewed by others

References

YEH Jien-wei, CHEN Swe-kai, LIN Su-jien, et al. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes [J]. Advanced Engineering Materials, 2004, 6(5): 299–303. DOI: https://doi.org/10.1002/adem.200300567.

HUANG Liu-fei, SUN Yao-ning, WANG Guo-jian. Research progress of laser cladding high-entropy alloy coating [J]. Laser & Optoelectronics Progress, 2019, 56(24): 34–41. DOI: https://doi.org/10.3788/LOP56.240003. (in Chinese)

REN Ming-xing, LI Bang-sheng, FU Heng-zhi. Formation condition of solid solution type high-entropy alloy [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(4): 991–995. DOI: https://doi.org/10.1016/S1003-6326(13)62557-1.

AN Zi-bing, MAO Sheng-cheng, YANG Tao, et al. Simultaneously enhanced oxidation resistance and mechanical properties in a novel lightweight Ti2VZrNb0.5Al0.5 high-entropy alloy [J]. Science China Materials, 2022, 65(10): 2842–2849. DOI: https://doi.org/10.1007/s40843-022-2045-4.

XIAO Wei-cheng, LI Kun, HAN Liu-liu, et al. Self-lubricating behavior of Fe22Co26Cr20Ni22Ta10 high-entropy alloy matrix composites [J]. Transactions of Nonferrous Metals Society of China, 2021, 31(3): 744–752. DOI: https://doi.org/10.1016/S1003-6326(21)65535-8.

DU Yu-hang, DING De-yu, GUO Ning, et al. The progress of high-entropy alloys with the functional properties [J]. Materials Reports, 2021, 35(17): 17051–17063. DOI: https://doi.org/10.11896/cldb.21030186. (in Chinese)

KARIMI M A, SHAMANIAN M, ENAYATI M H. Microstructural and mechanical properties assessment of transient liquid phase bonding of CoCuFeMnNi high entropy alloy [J]. Transactions of Nonferrous Metals Society of China, 2021, 31(10): 3063–3074. DOI: https://doi.org/10.1016/S1003-6326(21)65715-1.

ZHANG Li-song, ZHANG Xiao-nan, LI Na, et al. Study on thermal shock irradiation resistance of CoCrFeMnNi high entropy alloy by high intensity pulsed ion beam [J]. Journal of Nuclear Materials, 2022, 559: 153413. DOI: https://doi.org/10.1016/j.jnucmat.2021.153413.

REN Xian-li, ZHANG Wei-wei, WU Xiao-yong, et al. Prediction of short range order in high-entropy alloys and its effect on the electronic, magnetic and mechanical properties [J]. Acta Physica Sinica, 2020, 69: 46102–1. DOI: https://doi.org/10.7498/APS.69.20191671.

TIAN Feng-jie, LIU Wei-jun, SHANG Xiao-feng. Study on green remanufacturing technology based on laser cladding [J]. Manufacturing Technology & Machine Tool, 2009(2): 110–114. DOI: https://doi.org/10.1109/MILCOM.2009.5379889. (in Chinese)

WU Ying, LIU Yan, CHEN Wen-jing, et al. Research status and development direction of extreme high-speed laser material deposition [J]. Electric Welding Machine, 2020, 50(3): 1–10. DOI: https://doi.org/10.7512/j.issn.1001-2303.2020.03.01. (in Chinese)

ZHANG Kang, BAO Jun-feng, WANG Xing-yu. Research on the application of high-speed laser cladding technology [J]. Metallurgy and materials, 2021, 41(4): 66–68. DOI: https://doi.org/10.3969/j.issn.1674-5183.2021.04.031. (in Chinese)

HUANG Xu, ZHANG Jia-cheng, LIAN Guo-fu, et al. Research status and application of extreme high-speed cladding [J]. Machine Tool & Hydraulics, 2021, 49(6): 151–155. DOI: https://doi.org/10.3969/j.issn.1001-3881.2021.06.031. (in Chinese)

LOU Li-yan, ZHANG Yu, XU Qing-long, et al. Microstructure and properties of metallic coatings with low dilution ratio by high speed laser cladding [J]. China Surface Engineering, 2020, 33(2): 149–159.DOI: https://doi.org/10.11933/j.issn.10079289.20191118001. (in Chinese)

SHANG Xu-liang, WANG Zhi-jun, WU Qing-feng, et al. Effect of Mo addition on corrosion behavior of high-entropy alloys CoCrFeNiMox in aqueous environments [J]. Acta Metallurgica Sinica (English Letters), 2019, 32(1): 41–51. DOI: https://doi.org/10.1007/s40195-018-0812-7.

LIU W H, LU Z P, HE J Y, et al. Ductile CoCrFeNiMo, high entropy alloys strengthened by hard intermetallic phases [J]. Acta Materialia, 2016, 116: 332–342. DOI: https://doi.org/10.1016/j.actamat.2016.06.063.

LIU Qian, WANG Xin-yang, HUANG Yan-bin, et al. Effect of molybdenum content on microstructure and corrosion resistance of CoCrFeNiMo high-entropy alloy [J]. Chinese Journal of Materials Research, 2020, 34(11): 868–874. DOI: https://doi.org/10.11901/1005.3093.2020.269. (in Chinese)

WANG Qin, AMAR A, JIANG Chun-li, et al. CoCrFeNiMo0.2 high entropy alloy by laser melting deposition: Prospective material for low temperature and corrosion resistant applications [J]. Intermetallics, 2020, 119: 106727. DOI: https://doi.org/10.1016/j.intermet.2020.106727.

LIU Li-qun, SHEN Fa-ming, ZHOU Yuan-dong, et al. Comparison of microstructure and corrosion resistance of 431 stainless steel coatings prepared by extreme high-speed laser cladding and conventional laser cladding [J]. Chinese Journal of Lasers, 2019, 46: 1002010. DOI: https://doi.org/10.3788/CJL201946.1002010.

XU Yi-fei, SUN Yao-ning, WANG Guo-jian, et al. Microstructure and properties of iron-based alloys coatings prepared by high-speed laser cladding [J]. Chinese Journal of Lasers, 2021, 48(10): 222–230. DOI: https://doi.org/10.3788/CJL202148.1002122. (in Chinese)

CHANDRA D. Comparison of physico-mechanical properties of TiO2 and Cr2O3 additives on reaction sintered zirconia-mullite composites [J]. China’s Refractories, 2019, 28(1): 11–21. DOI: https://doi.org/10.19691/j.cnki.1004-4493.2019.01.003. (in Chinese)

WANG Xue-hui, WANG Ji-hui, FU Cong-wei. Characterization of pitting corrosion of 7A60 aluminum alloy by EN and EIS techniques [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(12): 3907–3916. DOI: https://doi.org/10.1016/S1003-6326(14)63550-0.

XIA Han, ZHANG Cong-lin, LV Peng, et al. Surface alloying of aluminum with molybdenum by high-current pulsed electron beam [J]. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions With Materials and Atoms, 2018, 416: 9–15. DOI: https://doi.org/10.1016/j.nimb.2017.11.028.

CHEN Ya-nan, LV Peng, ZHANG Shu-yao, et al. Microstructure modification and corrosion resistance of CrFeCoNiMo0.2 high-entropy alloy induced by high-current pulsed electron beam [J]. Surface Technology, 2020, 49(10): 214–223. DOI: https://doi.org/10.16490/j.cnki.issn.1001-3660.2020.10.024. (in Chinese)

ZHANG Xian-man, CHEN Zai-yu, LUO Hong-feng, et al. Corrosion resistances of metallic materials in environments containing chloride ions: A review [J]. Transactions of Nonferrous Metals Society of China, 2022, 32(2): 377–410. DOI: https://doi.org/10.1016/S1003-6326(22)65802-3.

WANG Yin, WANG Yue-ting, LI Rui-di, et al. Hall-Petch relationship in selective laser melting additively manufactured metals: Using grain or cell size? [J]. Journal of Central South University, 2021, 28(4): 1043–1057. DOI: https://doi.org/10.1007/s11771-021-4678-x.

HE Yu-qing, PENG Chao-qun, WANG Ri-chu, et al. Effect of extrusion on corrosion behavior of Mg-10Li-5Al-0.02Zr alloy [J]. The Chinese Journal of Nonferrous Metals, 2019, 29(5): 896–905. DOI: https://doi.org/10.19476/j.ysxb.1004.0609.2019.05.02. (in Chinese)

Funding

Project(2020E0264) supported by the Xinjiang Science and Technology Project Plan of Autonomous Region, China; Project(2020D01C030) supported by the Autonomous Region Natural Science Foundation, China

Author information

Authors and Affiliations

Corresponding author

Additional information

Contributors

The overarching research goals were developed by SUN Yao-ning, CHENG Wang-jun, and MA Xu-feng. MA Xu-feng, CHONG Zhen-zeng and MENG A-cong provided the surface morphologies data, and analyzed the measured data. MA Xu-feng, JIANG Li-heng and HUANG Liu-fei provided the figures of macro and micro of coatings. MA Xu-feng and CHONG Zhen-zeng took the electrochemical corrosion experiments. MA Xu-feng and CHENG Wang-jun analyzed the data of experiments results. The initial draft of the manuscript was written by MA Xu-feng, CHONG Zhen-zeng, and CHENG Wang-jun. All authors replied to reviewers’ comments and revised the final version.

Conflict of interest

MA Xu-feng, SUN Yao-ning, CHENG Wang-jun, CHONG Zhen-zeng, HUANG Liu-fei, MENG A-cong, and JIANG Li-heng declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Ma, Xf., Sun, Yn., Cheng, Wj. et al. Effect of high-speed laser cladding on microstructure and corrosion resistance of CoCrFeNiMo0.2 high-entropy alloy. J. Cent. South Univ. 29, 3436–3446 (2022). https://doi.org/10.1007/s11771-022-5162-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-5162-y