Abstract

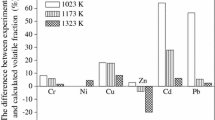

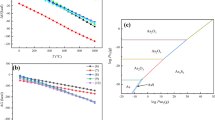

To recycle arsenic from an As-Sb fly ash, a newly continuous reductive method for obtaining elemental As with additive of PbO was proposed. In the first reduction stage, PbO promoted the As segregation from the As-Sb fly ash, due to which most As volatilized and Sb retained in roasted residues in phases of As-Sb-Pb-O and As-Sb-Pb alloy. With the increase of PbO and reductant amounts, the Sb fixation rate increased in the first reduction stage, and further the Sb content in the elemental As obtained from the second reduction stage decreased. After being roasted for 30 min at 550 °C with the addition of 20% activated carbon and 12% PbO in the first reduction stage, the As volatilization rate and Sb fixation rate from the As-Sb fly ash reached 92.86% and 79.38%, respectively. Then through the second reduction of the volatile matters at 650 ° C, the As and Sb contents in the obtained elemental As reached 99.07 wt% and 0.22 wt% respectively, indicating that the obtained As could be used to prepare high purity As, thereby rendering the As-Sb fly ash recycling.

摘要

为了实现砷锑烟尘中砷的循环利用,本文提出一种以PbO为添加剂,通过连续还原法从砷锑烟 尘中制备单质砷的方法。在第一段还原工艺中,以PbO为添加剂,砷大量挥发的同时将锑高效固定在 焙烧底物中,实现了砷、锑的高效分离;在第二段还原工艺中,将挥发砷物相还原为单质砷,实现了 砷的资源化利用。在PbO 作用下,第一还原阶段中锑以As-Sb-Pb-O 和As-Sb-Pb 合金形式存留在焙烧 底物中,当增加PbO 和还原剂用量时,锑固定效率增加,有效降低了第二还原阶段产物砷中的锑含 量。在第一还原阶段焙烧温度550 °C、活性炭添加量20%和PbO添加量12%,焙烧时间30 min 时,砷 锑烟尘中砷挥发效率为92.86%,锑固定效率达79.38%;挥发物经第二阶段650 °C还原后,所获得砷 产物中砷、锑含量分别为99.07 wt%和0.22 wt%。所获得的单质砷产物可作为制备高纯砷的原料,从而 实现了砷锑烟尘中砷的循环利用。

Similar content being viewed by others

References

GUO Xue-jun, WANG Kun-peng, HE Meng-chang, et al. Antimony smelting process generating solid wastes and dust: Characterization and leaching behaviors [J]. Journal of Environmental Sciences, 2014, 26(7): 1549–1556. DOI: https://doi.org/10.1016/j.jes.2014.05.022.

TAN Cheng, LI Hong-juan, LI Jin-yan, et al. Recovery of Sb and Fe from Sb-bearing slags through a reduction roasting process with low density polyethylene [J]. ISIJ International, 2019, 59(11): 2113–2119. DOI: https://doi.org/10.2355/isijinternational.isijint-2019-055.

SHAHNAZI A, FIROOZI S, HAGHSHENAS FATMEHSARI D. Selective leaching of arsenic from copper converter flue dust by Na2S and its stabilization with Fe2(SO4)3 [J]. Transactions of Nonferrous Metals Society of China, 2020, 30(6): 1674–1686. DOI: https://doi.org/10.1016/S1003-6326(20)65329-8.

LEI Tian-ya, SHU Jian-cheng, DENG Ya-ling, et al. Enhanced recovery of copper from reclaimed copper smelting fly ash via leaching and electrowinning processes [J]. Separation and Purification Technology, 2021, 273: 118943. DOI: https://doi.org/10.1016/j.seppur.2021.118943.

LIU Ya-ci, TIAN Xia, CAO Sheng-wei, et al. Pollution characteristics and health risk assessment of arsenic transformed from feed additive organoarsenicals around chicken farms on the North China Plain [J]. Chemosphere, 2021, 278: 130438. DOI: https://doi.org/10.1016/j.chemosphere.2021.130438.

DAS A, JOARDAR M, DE A-yan, et al. Pollution index and health risk assessment of arsenic through different groundwater sources and its load on soil-paddy-rice system in a part of Murshidabad district of West Bengal, India [J]. Groundwater for Sustainable Development, 2021, 15: 100652. DOI: https://doi.org/10.1016/j.gsd.2021.100652.

YADAV M K, SAIDULU D, GUPTA A K, et al. Status and management of arsenic pollution in groundwater: A comprehensive appraisal of recent global scenario, human health impacts, sustainable field-scale treatment technologies [J]. Journal of Environmental Chemical Engineering, 2021, 9(3): 105203. DOI: https://doi.org/10.1016/j.jece.2021.105203.

PARK I, RYOTA T, YUTO T, et al. A novel arsenic immobilization strategy via a two-step process: Arsenic concentration from dilute solution using schwertmannite and immobilization in Ca-Fe-AsO4 compounds [J]. Journal of Environmental Management, 2021, 295: 113052. DOI: https://doi.org/10.1016/j.jenvman.2021.113052.

RONG Zhi-hao, TANG Xin-cun, WU Li-ping, et al. A novel method to synthesize scorodite using ferrihydrite and its role in removal and immobilization of arsenic [J]. Journal of Materials Research and Technology, 2020, 9(3): 5848–5857. DOI: https://doi.org/10.1016/j.jmrt.2020.03.112.

GAO Ming-rui, SUN Qin, WANG Jin-hui, et al. Investigation of the combined use of capping and oxidizing agents in the immobilization of arsenic in sediments [J]. Science of the Total Environment, 2021, 782: 146930. DOI: https://doi.org/10.1016/j.scitotenv.2021.146930.

BANERJEE G, CHAKRABORTY R. Management of arsenic-laden water plant sludge by stabilization [J]. Clean Technologies and Environmental Policy, 2005, 7(4): 270–278. DOI: https://doi.org/10.1007/s10098-005-0275-1.

ZENG Li-na, LI Lin, YANG Yun-fan, et al. Morphology characterization and growth of GaAs nanowires on selective-area substrates [J]. Chemical Physics Letters, 2021, 779: 138887. DOI: https://doi.org/10.1016/j.cplett.2021.138887.

AKIYAMA T, YONEMOTO K, HISHIKI F, et al. Effect of surface structural change on adsorption behavior on InAs wetting layer surface grown on GaAs(001) substrate [J]. Journal of Crystal Growth, 2021, 570: 126233. DOI: https://doi.org/10.1016/j.jcrysgro.2021.126233.

LU Hong-bo. Thermodynamic analysis on crude metal arsenic preparation by arsenic trioxide carbothermic reduction in vacuum [J]. Nonferrous MetalsExtractive Metallurgy), 2012(10): 55–59. DOI: https://doi.org/10.3969/J.issn.1007-7545.2012.10.016. (in Chinese)

LI Wen-hua, HAN Jun-wei, LIU Wei, et al. Separation of arsenic from lead smelter ash by acid leaching combined with pressure oxidation [J]. Separation and Purification Technology, 2021, 273: 118988. DOI: https://doi.org/10.1016/j.seppur.2021.118988.

GU Kun-hong, LIU Wei, HAN Jun-wei, et al. Arsenic and antimony extraction from high arsenic smelter ash with alkaline pressure oxidative leaching followed by Na2S leaching [J]. Separation and Purification Technology, 2019, 222: 53–59. DOI: https://doi.org/10.1016/j.seppur.2019.04.028.

GU Kun-hong, LI Wen-hua, HAN Jun-wei, et al. Arsenic removal from lead-zinc smelter ash by NaOH-H2O2 leaching [J]. Separation and Purification Technology, 2019, 209: 128–135. DOI: https://doi.org/10.1016/j.seppur.2018.07.023.

SHI Teng-teng, HE Ji-lin, ZHU Rong-bo, et al. Arsenic removal from arsenic-containing copper dust by vacuum carbothermal reduction-vulcanization roasting [J]. Vacuum, 2021, 189: 110213. DOI: https://doi.org/10.1016/j.vacuum.2021.110213.

YU Yong, LI Lei, WANG Jing-cheng. Sn recovery from a tin-bearing middling with a high iron content and the transformation behaviours of the associated As, Pb, and Zn [J]. Science of the Total Environment, 2020, 744: 140863. DOI: https://doi.org/10.1016/j.scitotenv.2020.140863.

DAI Yong-nian, HE Ai-ping, ZHAO Jia-de, et al. Vacuum distillation of Sn-As-Pb alloy (carbon slag) [J]. Journal of Kunming University of Science and Technology (Natural Sciences Edition), 1974(3): 47–65. DOI: https://doi.org/10.16112/j.cnki.53-1223/n.1979.03.004. (in Chinese)

FENG Jun, CLEMENT R, RAYNOR M. Characterization of high-purity arsine and gallium arsenide epilayers grown by MOCVD [J]. Journal of Crystal Growth, 2008, 310(23): 4780–4785. DOI: https://doi.org/10.1016/j.jcrysgro.2008.08.023.

ALLAIRE A, HARRIS R. Vacuum distillation of copper matte to remove lead, arsenic, bismuth, and antimony [J]. Metallurgical and Materials Transactions B, 1989, 20(6): 793–804. DOI: https://doi.org/10.1007/BF02670185.

GUO Xue-yi, YI Yu, SHI Jing, et al. Leaching behavior of metals from high-arsenic dust by NaOH-Na2S alkaline leaching [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(2): 575–580. DOI: https://doi.org/10.1016/S1003-6326(16)64118-3.

GUO Xue-yi, SHI Jing, YI Yu, et al. Separation and recovery of arsenic from arsenic-bearing dust [J]. Journal of Environmental Chemical Engineering, 2015, 3(3): 2236–2242. DOI: https://doi.org/10.1016/j.jece.2015.06.028.

BROOKS G A, RANKIN W J. Solid-solution formation between arsenic and antimony oxides [J]. Metallurgical and Materials Transactions B, 1994, 25(6): 865–871. DOI: https://doi.org/10.1007/BF02662768.

BROOKS G A, RANKIN W J, GRAY N B. Thermal separation of arsenic and antimony oxides [J]. Metallurgical and Materials Transactions B, 1994, 25(6): 873–884. DOI: https://doi.org/10.1007/BF02662769. DOI: https://doi.org/10.1007/s11771-018-3880-y.

ZHONG Da-peng, LI Lei, TAN Cheng. Recovery of antimony from antimony-bearing dusts through reduction roasting process under CO — CO2 mixture gas atmosphere after firstly oxidation roasted [J]. Journal of Central South University, 2018, 25(8): 1904–1913. DOI: https://doi.org/10.1007/s11771-018-3880-y.

ZHONG Da-peng, LI Lei, TAN Cheng. Separation of arsenic from the antimony-bearing dust through selective oxidation using CuO [J]. Metallurgical and Materials Transactions B, 2017, 48(2): 1308–1314. DOI: https://doi.org/10.1007/s11663-016-0896-2.

TAN Cheng, LI Lei, LI Kong-zhai, et al. Separation of As from high As-Sb dust using Fe2O3 as a fixative under O2-N2 atmosphere [J]. Separation and Purification Technology, 2018, 194: 81–88. DOI: https://doi.org/10.1016/j.seppur.2017.11.026.

LI Lei, WANG Fu-you, ZHONG Da-peng, et al. Separation and recovery of antimony from high arsenic-bearing flue dusts through selective oxidation using MnO2 [J]. ISIJ International, 2017, 57(3): 581–586. DOI: https://doi.org/10.2355/isijinternational.isijint-2016-362.

WEN Xiao-chun, GUO Lei, BAO Qi-peng, et al. Efficient separation of lead and antimony metals from the Pb-Sb alloy by super-gravity technology [J]. Journal of Alloys and Compounds, 2019, 806: 1012–1021. DOI: https://doi.org/10.1016/j.jallcom.2019.07.211.

ZHANG Jia-yun. Metallurgical physical chemistry [M]. Beijing: Metallurgical Industry Press, 2021. (in Chinese)

LI Xue-peng. Experiment study on arsenic preparation by DC furnace [J]. Mining and Metallurgy, 2012, 21(3): 56–59. DOI: https://doi.org/10.3969/j.issn.1005-7854.2012.03.015. (in Chinese)

PENG Zhi-qiang, LIAO Ya-long, ZHOU Juan. Review and trend of preparation of high purity arsenic [J]. Chemical Industry and Engineering Progress, 2013, 32(12):2929–2933. DOI: https://doi.org/10.3969/j.issn.1000-6613.2013.12.023. (in Chinese)

GOTT M D, DEGRAFFENREID A J, FENG Yu-tian, et al. Chromatographic separation of germanium and arsenic for the production of high purity 77As [J]. Journal of Chromatography A, 2016, 1441: 68–74. DOI: https://doi.org/10.1016/j.chroma.2016.02.074.

LIU Jing-xin, HUANG Si-mian, CHEN Kai, et al. Recovering metallic Pb directly from lead smelting dust by NaOH-carbon roasting process [J]. Journal of Materials Research and Technology, 2020, 9(3): 2744–2753. DOI: https://doi.org/10.1016/j.jmrt.2020.01.007.

XU Jun-jie, XU Shuai, KONG Ling-xin, et al. Investigation on recycling of lead and antimony from Pb-Sb Alloys by vacuum distillation [J]. Journal of Kunming University of Science and Technology (Natural Science Edition), 2017, 42(4): 9–13. DOI: https://doi.org/10.16112/j.cnki.53-1223/n.2017.04.002. (in Chinese)

FU Cheng-cheng, HUA Yi-xin, RU Juan-jian, et al. Electrolytic separation of high purity Sb powders from Pb-containing Sb alloy in deep eutectic solvent [J]. Mining and Metallurgical, 2021, 30(5): 55–60. DOI: https://doi.org/10.3969/j.issn.1005-7854.2021.05.010. (in Chinese)

Author information

Authors and Affiliations

Contributions

LI Lei performed the data analyses and wrote the manuscript. XU Miao performed the analysis with constructive discussions. XIAO Yang contributed to the validation of this study.

Corresponding author

Additional information

Conflict of interest

Lei LI, XU Miao and XIAO Yang declare that they have no conflict of interest.

Foundation item: Project(51874153) supported by the National Natural Science Foundation of China; Project(LZB2021003) supported by Fundamental Research Funds for the Central Universities, DHU Distinguished Young Professor Program, China

Rights and permissions

About this article

Cite this article

Li, L., Xu, M. & Xiao, Y. Preparation of elemental As from As-Sb fly ash using continuous reductive method with additive of lead oxide. J. Cent. South Univ. 29, 3003–3015 (2022). https://doi.org/10.1007/s11771-022-5146-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-5146-y