Abstract

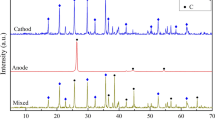

In this study, a roasting enhanced flotation process was proposed to recover LiMn2O4 and grapite from waste lithium-ion batteries (LIBs). The effects of roasting temperature and time on the surface modification was investigated, and a series of analytical technologies were used to reveal process mechanism. The results indicate that LiMn2O4 can be effectively separated from graphite via flotation after the roasting. The flotation grade of LiMn2O4 was significantly increased from 63.10% to 91.36% after roasting at 550 °C for 2 h. The TG-DTG analysis demonstrates that the difficulty in flotation separation of LiMn2O4 from graphite is caused by the organic binder and electrolytes coating on their surfaces. The XRD, SEM, XPS, and contact angle analyses confirm that the organic films on the surfaces of those materials can be effectively removed by roasting, after which the wettability of LiMn2O4 is regained and thus the surface wettability difference between the cathode and anode materials is increased significantly. The closed-circuit flotation test indicates that a LiMn2O4 sample with high grade of 99.81% is obtained, while the recovery of LiMn2O4 is as high as 99.40%. This study provides an economical and eco-friendly way to recycling waste LIBs.

摘要

本文提出用焙烧强化浮选法从废旧锂离子电池中回收LiMn2O4和石墨,研究了焙烧温度和焙烧时间对电极颗粒表面改性的影响,并采用一系列分析技术揭示了焙烧改性的机理。结果表明,焙烧改性后,浮选可使锰酸锂和石墨高效分离。电极活性材料在550 ℃下焙烧2 h 后,LiMn2O4的浮选品位从未焙烧的63.10% 显著提高到焙烧后的91.36%。通过电极活性材料的表面性质进行分析可知,造成LiMn2O4和石墨浮选分离困难的原因是电极颗粒表面被一层有机黏结剂和电解液包裹。利用XRD、SEM、XPS 和接触角分析技术,证明氧化焙烧可以有效去除电极材料表面的有机薄膜层,恢复LiMn2O4原本的亲水性表面,最终显著增加锰酸锂和石墨的表面润湿性差异。闭路浮选试验结果表明,最终获得的LiMn2O4产品,其品位和回收率分别为99.81% 和99.40%。本研究为废旧锂离子电池的资源化回收提供了一种经济环保的方法。

Similar content being viewed by others

References

BERTUOL D A, TONIASSO C, JIMÉNEZ B M, et al. Application of spouted bed elutriation in the recycling of lithium ion batteries [J]. Journal of Power Sources, 2015, 275: 627–632. DOI: https://doi.org/10.1016/j.jpowsour.2014.11.036.

ZENG Xian-lai, LI Jin-hui, LIU Li-li. Solving spent lithiumion battery problems in China: Opportunities and challenges [J]. Renewable and Sustainable Energy Reviews, 2015, 52: 1759–1767. DOI: https://doi.org/10.1016/j.rser.2015.08.014.

TARASCON J M, ARMAND M. Issues and challenges facing rechargeable lithium batteries [J]. Nature, 2001, 414(6861): 359–367. DOI: https://doi.org/10.1038/35104644.

NITTA N, WU Fei-xiang, LEE J T, et al. Li-ion battery materials: Present and future [J]. Materials Today, 2015, 18(5): 252–264. DOI: https://doi.org/10.1016/j.mattod.2014.10.040.

ZHANG Yue, OUYANG Yan, LIU Li, et al. Synthesis and characterization of Na0.44MnO2 nanorods/graphene composite as cathode materials for sodium-ion batteries [J]. Journal of Central South University, 2019, 26(6): 1510–1520. DOI: https://doi.org/10.1007/s11771-019-4107-6.

TRÄGER T, FRIEDRICH B, WEYHE R. Recovery concept of value metals from automotive lithium-ion batteries [J]. Chemie Ingenieur Technik, 2015, 87(11): 1550–1557. DOI: https://doi.org/10.1002/cite.201500066.

HARPER G, SOMMERVILLE R, KENDRICK E, et al. Recycling lithium-ion batteries from electric vehicles [J]. Nature, 2019, 575(7781): 75–86. DOI: https://doi.org/10.1038/s41586-019-1682-5.

ZHOU Li-feng, YANG Dong-run, DU Tao, et al. The current process for the recycling of spent lithium ion batteries [J]. Frontiers in Chemistry, 2020, 8: 578044. DOI: https://doi.org/10.3389/fchem.2020.578044.

LI Hao-yu, YE Hua, SUN Ming-cang, et al. Process for recycle of spent lithium iron phosphate battery via a selective leaching-precipitation method [J]. Journal of Central South University, 2020, 27(11): 3239–3248. DOI: https://doi.org/10.1007/s11771-020-4543-3.

RUISMÄKI R, RINNE T, DAŃCZAK A, et al. Integrating flotation and pyrometallurgy for recovering graphite and valuable metals from battery scrap [J]. Metals, 2020, 10(5): 680. DOI: https://doi.org/10.3390/met10050680.

HUANG Bin, PAN Zhe-fei, SU Xiang-yu, et al. Recycling of lithium-ion batteries: Recent advances and perspectives [J]. Journal of Power Sources, 2018, 399: 274–286. DOI: https://doi.org/10.1016/j.jpowsour.2018.07.116.

FAN Xiao-ping, SONG Chun-hong, LU Xi-fei, et al. Separation and recovery of valuable metals from spent lithium-ion batteries via concentrated sulfuric acid leaching and regeneration of LiNi1/3Co1/3Mn1/3O2 [J]. Journal of Alloys and Compounds, 2021, 863: 158775. DOI: https://doi.org/10.1016/j.jallcom.2021.158775.

PENG Chao, LIU Fu-peng, WANG Zu-lin, et al. Selective extraction of lithium (Li) and preparation of battery grade lithium carbonate (Li2CO3) from spent Li-ion batteries in nitrate system [J]. Journal of Power Sources, 2019, 415: 179–188. DOI: https://doi.org/10.1016/j.jpowsour.2019.01.072.

CHIU Kai-lun, CHEN Wei-sheng. Recovery and separation of valuable metals from cathode materials of spent lithiumion batteries (LIBs) by ion exchange [J]. Science of Advanced Materials, 2017, 9(12): 2155–2160. DOI: https://doi.org/10.1166/sam.2017.3214.

ZENG Xian-lai, LI Jin-hui, SINGH N. Recycling of spent lithium-ion battery: A critical review [J]. Critical Reviews in Environmental Science and Technology, 2014, 44(10): 1129–1165. DOI: https://doi.org/10.1080/10643389.2013.763578.

ZHANG Guang-wen, HE Ya-qun, FENG Yi, et al. Pyrolysis-ultrasonic-assisted flotation technology for recovering graphite and LiCoO2 from spent lithium-ion batteries [J]. ACS Sustainable Chemistry & Engineering, 2018, 6(8): 10896–10904. DOI: https://doi.org/10.1021/acssuschemeng.8b02186.

ZHANG Guang-wen, YUAN Xue, HE Ya-qun, et al. High-efficiency liberation and flotation enhancement of electrode materials derived from spent lithium-ion during pyrolysis pretrement[J]. Journal of Central South University (Science and Technology), 2021, 52(4): 1058–1065. DOI: https://doi.org/10.11817/j.issn.1672-7207.2021.04.002. (in Chinese)

ZHANG Guang-wen, HE Ya-qun, WANG Hai-feng, et al. Application of mechanical crushing combined with pyrolysis-enhanced flotation technology to recover graphite and LiCoO2 from spent lithium-ion batteries [J]. Journal of Cleaner Production, 2019, 231: 1418–1427. DOI: https://doi.org/10.1016/j.jclepro.2019.04.279.

ZHANG Tao, HE Ya-qun, WANG Fang-fang, et al. Surface analysis of cobalt-enriched crushed products of spent lithiumion batteries by X-ray photoelectron spectroscopy [J]. Separation and Purification Technology, 2014, 138: 21–27. DOI: https://doi.org/10.1016/j.seppur.2014.09.033.

LIANG Zhi-lin, CAI Chen, PENG Gang-wei, et al. Hydrometallurgical recovery of spent lithium ion batteries: Environmental strategies and sustainability evaluation [J]. ACS Sustainable Chemistry & Engineering, 2021, 9(17): 5750–5767. DOI: https://doi.org/10.1021/acssuschemeng.1c00942.

YAO Yong-lin, ZHU Mei-ying, ZHAO Zhuo, et al. Hydrometallurgical processes for recycling spent lithium-ion batteries: A critical review [J]. ACS Sustainable Chemistry & Engineering, 2018, 6(11): 13611–13627. DOI: https://doi.org/10.1021/acssuschemeng.8b03545.

ZHANG Guang-wen, YUAN Xue, HE Ya-qun, et al. Organics removal combined with in situ thermal-reduction for enhancing the liberation and metallurgy efficiency of LiCoO2 derived from spent lithium-ion batteries [J]. Waste Management, 2020, 115: 113–120. DOI: https://doi.org/10.1016/j.wasman.2020.05.030.

ZHONG Xue-hu, LIU Wei, HAN Jun-wei, et al. Pyrolysis and physical separation for the recovery of spent LiFePO4 batteries [J]. Waste Management, 2019, 89: 83–93. DOI: https://doi.org/10.1016/j.wasman.2019.03.068.

XIAO Jie-feng, LI Jia, XU Zhen-ming. Novel approach for in situ recovery of lithium carbonate from spent lithium ion batteries using vacuum metallurgy [J]. Environmental Science & Technology, 2017, 51(20): 11960–11966. DOI: https://doi.org/10.1021/acs.est.7b02561.

LI Jia, WANG Guang-xu, XU Zhen-ming. Environmentally-friendly oxygen-free roasting/wet magnetic separation technology for in situ recycling cobalt, lithium carbonate and graphite from spent LiCoO2/graphite lithium batteries [J]. Journal of Hazardous Materials, 2016, 302: 97–104. DOI: https://doi.org/10.1016/j.jhazmat.2015.09.050.

ZHANG Guang-wen, DU Zhong-xing, HE Ya-qun, et al. A sustainable process for the recovery of anode and cathode materials derived from spent lithium-ion batteries [J]. Sustainability, 2019, 11(8): 2363. DOI: https://doi.org/10.3390/su11082363.

ZHANG Tao, HE Ya-qun, WANG Fang-fang, et al. Chemical and process mineralogical characterizations of spent lithiumion batteries: An approach by multi-analytical techniques [J]. Waste Management, 2014, 34(6): 1051–1058. DOI: https://doi.org/10.1016/j.wasman.2014.01.002.

ZHANG Guang-wen, HE Ya-qun, WANG Hai-feng, et al. Removal of organics by pyrolysis for enhancing liberation and flotation behavior of electrode materials derived from spent lithium-ion batteries [J]. ACS Sustainable Chemistry & Engineering, 2020, 8(5): 2205–2214. DOI: https://doi.org/10.1021/acssuschemeng.9b05896.

AL-THYABAT S, NAKAMURA T, SHIBATA E, et al. Adaptation of minerals processing operations for lithium-ion (LiBs) and nickel metal hydride (NiMH) batteries recycling: Critical review [J]. Minerals Engineering, 2013, 45: 4–17. DOI: https://doi.org/10.1016/j.mineng.2012.12.005.

YU Jia-dong, HE Ya-qun, GE Zhen-zhou, et al. A promising physical method for recovery of LiCoO2 and graphite from spent lithium-ion batteries: Grinding flotation [J]. Separation and Purification Technology, 2018, 190: 45–52. DOI: https://doi.org/10.1016/j.seppur.2017.08.049.

HE Ya-qun, ZHANG Tao, WANG Fang-fang, et al. Recovery of LiCoO2 and graphite from spent lithium-ion batteries by Fenton reagent-assisted flotation [J]. Journal of Cleaner Production, 2017, 143: 319–325. DOI: https://doi.org/10.1016/j.jclepro.2016.12.106.

YU Jia-dong, HE Ya-qun, LI Hong, et al. Effect of the secondary product of semi-solid phase Fenton on the flotability of electrode material from spent lithium-ion battery [J]. Powder Technology, 2017, 315: 139–146. DOI: https://doi.org/10.1016/j.powtec.2017.03.050.

YU Jia-dong, HE Ya-qun, QU Li-li, et al. Exploring the critical role of grinding modification on the flotation recovery of electrode materials from spent lithium ion batteries [J]. Journal of Cleaner Production, 2020, 274: 123066. DOI: https://doi.org/10.1016/j.jclepro.2020.123066.

LIU Jiang-shan, WANG Hai-feng, HU Ting-ting, et al. Recovery of LiCoO2 and graphite from spent lithium-ion batteries by cryogenic grinding and froth flotation [J]. Minerals Engineering, 2020, 148: 106223. DOI: https://doi.org/10.1016/j.mineng.2020.106223.

CHOI S S, KIM Y K. Microstructural analysis of poly (vinylidene fluoride) using benzene derivative pyrolysis products [J]. Journal of Analytical and Applied Pyrolysis, 2012, 96: 16–23. DOI: https://doi.org/10.1016/j.jaap.2012.02.014.

HAO Juan, WANG Hai-feng, CHEN Shu-he, et al. Pyrolysis characteristics of the mixture of printed circuit board scraps and coal powder [J]. Waste Management, 2014, 34(10): 1763–1769. DOI: https://doi.org/10.1016/j.wasman.2013.10.043.

LIU Wei, XU Jia-qi, HAN Jun-wei, et al. Kinetic and mechanism studies on pyrolysis of printed circuit boards in the absence and presence of copper [J]. ACS Sustainable Chemistry & Engineering, 2019, 7(2): 1879–1889. DOI: https://doi.org/10.1021/acssuschemeng.8b03382.

YANG Yue, HUANG Guo-yong, XU Sheng-ming, et al. Thermal treatment process for the recovery of valuable metals from spent lithium-ion batteries [J]. Hydrometallurgy, 2016, 165: 390–396. DOI: https://doi.org/10.1016/j.hydromet.2015.09.025.

ZHANG Guang-wen, HE Ya-qun, FENG Yi, et al. Enhancement in liberation of electrode materials derived from spent lithium-ion battery by pyrolysis [J]. Journal of Cleaner Production, 2018, 199: 62–68. DOI: https://doi.org/10.1016/j.jclepro.2018.07.143.

ZHONG Xue-hu, HAN Jun-wei, CHEN Ling-ling, et al. Binding mechanisms of PVDF in lithium ion batteries [J]. Applied Surface Science, 2021, 553: 149564. DOI: https://doi.org/10.1016/j.apsusc.2021.149564.

CHEN Yong-ming, LIU Nan-nan, HU Fang, et al. Thermal treatment and ammoniacal leaching for the recovery of valuable metals from spent lithium-ion batteries [J]. Waste Management, 2018, 75: 469–476. DOI: https://doi.org/10.1016/j.wasman.2018.02.024.

WANG Fang-fang, ZHANG Tao, HE Ya-qun, et al. Recovery of valuable materials from spent lithium-ion batteries by mechanical separation and thermal treatment [J]. Journal of Cleaner Production, 2018, 185: 646–652. DOI: https://doi.org/10.1016/j.jclepro.2018.03.069.

ZHONG Xue-hu, LIU Wei, HAN Jun-wei, et al. Pretreatment for the recovery of spent lithium ion batteries: Theoretical and practical aspects [J]. Journal of Cleaner Production, 2020, 263: 121439. DOI: https://doi.org/10.1016/j.jclepro.2020.121439.

ZHONG Xue-hu, LIU Wei, HAN Jun-wei, et al. Pneumatic separation for crushed spent lithium-ion batteries [J]. Waste Management, 2020, 118: 331–340. DOI: https://doi.org/10.1016/j.wasman.2020.08.053.

Author information

Authors and Affiliations

Contributions

The overarching research goals were developed by HAN Jun-wei. The initial draft of the manuscript was written by CHEN Ling-ling and HAN Jun-wei. All authors analyzed the results. HAN Jun-wei and QIN Wen-qing provided resources and funding support. HAN Jun-wei and CHEN Ling-ling replied to the reviewers’ comments and revised the final version.

Corresponding author

Additional information

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Foundation item: Project(2021JJ20062) supported by the Natural Science Foundation of Hunan Province, China; Project(2019XK2304) supported by Landmark Innovation Demonstration Project of Hunan Province, China; Project(2022GK4058) supported by High-tech Industry Science and Technology Innovation Leading Project of Hunan Province, China; Project (2020CX038) supported by the Innovation Driven Project of Central South University, China; Project (2019YFC1907301) supported by the National Key R&D Program of China; Project(202006375018) supported by the China Scholarship Council

Rights and permissions

About this article

Cite this article

Han, Jw., Chen, Ll., Zhong, Xh. et al. A promising method for recovery of LiMn2O4 and graphite from waste lithium-ion batteries: Roasting enhanced flotation. J. Cent. South Univ. 29, 2873–2887 (2022). https://doi.org/10.1007/s11771-022-5127-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-5127-1