Abstract

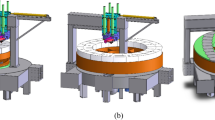

This study investigates the factors affecting the rock-breaking efficiency of the TBM disc cutter in deep rock excavation, including confining pressure, penetration, cutter spacing, and revolution speed. The finite element method is employed to formulate a rock-breaking model of the rotary disc cutters and a numerical simulation is also implemented. The rock breaking effect, rock breaking volume, and rock breaking specific energy consumption under different combinations of the factors are investigated. An orthogonal test of four factors at four levels was constructed. Based on the test results and range analysis in the process of deep rock mass breaking, the order of sensitivity of each influencing factor with respect to the rock breaking specific energy for the disc cutter is cutter spacing > revolution speed > penetration > confining pressure. By constructing a numerical simulation comparison scheme, the orthogonal test results are analyzed and corroborated, and the rock breaking law and rock breaking efficiency under different influencing factors are derived. Finally, the sensitivity of different influencing factors on the rock-breaking efficiency is verified.

摘要

k]为了研究TBM 在深部岩体开挖过程中多种因素对盘形滚刀破岩效率的影响, 考虑了不同围压、贯入度、刀间距和公转速度因素的影响, 采用有限元法建立盘形滚刀回转切割破岩模型并进行数值模拟, 研究不同影响因素组合下的破岩效果、岩石破碎体积和破岩比能耗. 为了得出影响破岩效率的最敏感因素, 构建了4 因素4 水平的正交试验. 研究结果表明:在深部岩体破岩过程中, 影响因素对盘形滚刀破岩比能耗敏感度的顺序依次为刀间距、公转速度、贯入度和围压, 即刀间距是影响盘形滚刀破岩效率的主要因素. 通过数值模拟对比分析验证正交试验结果, 得出不同影响因素下的破岩规律和破岩效率, 进而验证了不同影响因素对破岩效率的敏感度.

Similar content being viewed by others

Reference

GONG Feng-qiang, SI Xue-feng, LI Xi-bing, et al. Experimental investigation of strain rockburst in circular caverns under deep three-dimensional high-stress conditions [J]. Rock Mechanics and Rock Engineering, 2019, 52(5): 1459–1474. DOI: https://doi.org/10.1007/s00603-018-1660-5.

MU Wen-qiang, LI Lian-chong, YANG Tian-hong, et al. Numerical investigation on a grouting mechanism with slurry-rock coupling and shear displacement in a single rough fracture [J]. Bulletin of Engineering Geology and the Environment, 2019, 78(8): 6159–6177. DOI: https://doi.org/10.1007/s10064-019-01535-w.

GONG Q M, YIN L J, WU S Y, et al. Rock burst and slabbing failure and its influence on TBM excavation at headrace tunnels in Jinping II hydropower station [J]. Engineering Geology, 2012, 124: 98–108. DOI: https://doi.org/10.1016/j.enggeo.2011.10.007. (in Chinese)

LI X J, YANG W M, WANG L G, et al. Displacement forecasting method in brittle crack surrounding rock under excavation unloading incorporating opening deformation [J]. Rock Mechanics and Rock Engineering, 2014, 47(6): 2211–2223. DOI: https://doi.org/10.1007/s00603-014-0599-4. (in Chinese)

LI Xiao-jing, WANG Li-ge, YANG Wei-min. A numerical study of underground cavern stability by geostress characteristics [J]. Shock and Vibration, 2016, 2016: 3768453. DOI: https://doi.org/10.1155/2016/3768453.

WU Zhi-jun, JIANG Ya-long, LIU Quan-sheng, et al. Investigation of the excavation damaged zone around deep TBM tunnel using a Voronoi-element based explicit numerical manifold method [J]. International Journal of Rock Mechanics and Mining Sciences, 2018, 112: 158–170. DOI: https://doi.org/10.1016/j.ijrmms.2018.10.022.

SHI Yu-peng, XIA Yi-min, TAN Qing, et al. Distribution of contact loads in crushed zone between tunnel boring machine disc cutter and rock [J]. Journal of Central South University, 2019, 26(9): 2393–2403. DOI: https://doi.org/10.1007/s11771-019-4182-8.

INNAURATO N, OGGERI C, ORESTE P P, et al. Experimental and numerical studies on rock breaking with TBM tools under high stress confinement [J]. Rock Mechanics and Rock Engineering, 2006, 40(5): 429–451. DOI: https://doi.org/10.1007/s00603-006-0109-4.

HONG Kai-rong, LIU He-ping, ZHANG Wei. Study on mechanism of rock fragmentation of TBM disc cutter [J]. Advanced Materials Research, 2011, 399–401: 2116–2124. DOI: https://doi.org/10.4028/www.scientific.net/amr.399-401.2116.

HAN D Y, CAO P, LIU J, et al. An experimental study of dependence of optimum TBM cutter spacing on pre-set penetration depth in sandstone fragmentation [J]. Rock Mechanics and Rock Engineering, 2017, 50(12): 3209–3221. DOI: https://doi.org/10.1007/s00603-017-1275-2. (in Chinese)

LIU Jie, CAO Ping, HAN Dong-ya. The influence of confining stress on optimum spacing of TBM cutters for cutting granite [J]. International Journal of Rock Mechanics and Mining Sciences, 2016, 88: 165–174. DOI: https://doi.org/10.1016/j.ijrmms.2016.07.017

GERTSCH R, GERTSCH L, ROSTAMI J. Disc cutting tests in Colorado red granite: Implications for TBM performance prediction [J]. International Journal of Rock Mechanics and Mining Sciences, 2007, 44(2): 238–246. DOI: https://doi.org/10.1016/j.ijrmms.2006.07.007.

GHAZVINIAN A, HADEI M R. Effect of discontinuity orientation and confinement on the strength of jointed anisotropic rocks [J]. International Journal of Rock Mechanics and Mining Sciences, 2012, 55: 117–124. DOI: https://doi.org/10.1016/j.ijrmms.2012.06.008.

ZHANG Kui, XIA Yi-min, TAN Qing, et al. Numerical study on modes of breaking rock by TBM cutter under different confining pressures [J]. Chinese Journal of Geotechnical Engineering, 2010, 32(11): 1780–1787. (in Chinese)

GONG Qiu-ming, HE Guan-wen, ZHAO Xiao-bao, et al. Influence of different cutter spacings on rock fragmentation efficiency of Beishan granite by TBM [J]. Chinese Journal of Geotechnical Engineering, 2015, 37(1): 54–60. (in Chinese)

GONG Qiu-ming, SHE Qi-rui, HOU Zhe-sheng, et al. Experimental study of tbm penetration in marble rock mass under high geostress [J]. Chinese Journal of Rock Mechanics and Engineering, 2010, 29(12): 2522–2532. (in Chinese)

CHENG Yong-liang. Numerical simulation on optimal penetration of TBM disc cutter’s rock fragmentation [J]. Journal of Central South University (Science and Technology), 2017, 48(4): 936–943. (in Chinese)

HONG Kai-rong, WANG Hai-xia, HAN Wei-feng. Simulation study of rock breaking with hob in soft and hard uneven composite stratum [C]// 3rd International Conference on Electrical, Control and Automation Engineering. Pennsylvania: ECAE, 2018: 310–314. DOI: https://doi.org/10.12783/dtetr/ecae2018/27749.

SU Li-jun, SUN Jin-shan, LU Wen-bo. Research on numerical simulation of rock fragmentation by TBM cutters using particle flow method [J]. Rock and Soil Mechanics, 2009, 30(9): 2823–2829. DOI: https://doi.org/10.16285/j.rsm.2009.09.050. (in Chinese)

SUN Jin-shan, CHEN Ming, CHEN Bao-guo, et al. Numerical simulation of influence factors for rock fragmentation by TBM cutters [J]. Rock and Soil Mechanics, 2011, 32(6): 1891–1897. DOI: https://doi.org/10.16285/j.rsm.2011.06.026.(in Chinese)

HAERI H, MARJI M F. Simulating the crack propagation and cracks coalescence underneath TBM disc cutters [J]. Arab Journal of Geography, 2016, 9(2): 124. DOI: https://doi.org/10.1007/s12517-015-2137-4. (in Chinese)

PENG Qi. Research on influence mechanism of confining pressure on rock breakage by TBM cutters [J]. Chinese Journal of Rock Mechanics and Engineering, 2014, 33(S1): 2743–2749. DOI: https://doi.org/10.13722/j.cnki.jrme.2014.s1.022. (in Chinese)

YU Jin, YAO Wei, DUAN Kang, et al. Experimental study and discrete element method modeling of compression and permeability behaviors of weakly anisotropic sandstones [J]. International Journal of Rock Mechanics and Mining Sciences, 2020, 134: 104437. DOI: https://doi.org/10.1016/j.ijrmms.2020.104437.

DAI Bing, SHAN Qi-wei, CHEN Ying, et al. Mechanical and energy dissipation characteristics of granite under cyclic impact loading [J]. Journal of Central South University, 2022, 29(1): 116–128. DOI: https://doi.org/10.1007/s11771-022-4897-9.

LIU K, CHEN S L. Finite element implementation of strain-hardening Drucker-Prager plasticity model with application to tunnel excavation [J]. Underground Space, 2017, 2(3): 168–174. DOI: https://doi.org/10.1016/j.undsp.2017.08.003.

LIANG Zheng-zhao, QIAN Xi-kun, ZHANG Ya-fang, et al. Numerical simulation of dynamic fracture properties of rocks under different static stress conditions [J]. Journal of Central South University, 2022, 29(2): 624–644. DOI: https://doi.org/10.1007/s11771-022-4903-2.

TAN Qing, ZHANG Xu-hui, XIA Yi-min, et al. Numerical study on breaking rock by disc cutter at different confining pressure and joint characteristics case [J]. Journal of China Coal Society, 2014, 39(7): 1220–1228. DOI: https://doi.org/10.13225/j.cnki.jccs.2013.1060. (in Chinese)

ZHANG Zi-xin, WANG Shuai-feng, HUANG Xin, et al. Application of block theory for evaluating face stability under disc cutters loading of TBM, case study of a water-conveyance tunnel project [J]. Tunnelling and Underground Space Technology, 2019, 90: 249–263. DOI: https://doi.org/10.1016/j.tust.2019.05.002.

PENG Xing-xin, LIU Quan-sheng, PAN Yu-cong, et al. Study on the influence of different control modes on TBM disc cutter performance by rotary cutting tests [J]. Rock Mechanics and Rock Engineering, 2018, 51(3): 961–967. DOI: https://doi.org/10.1007/s00603-017-1368-y.

FARROKH E, KIM D Y. A discussion on hard rock TBM cutter wear and cutterhead intervention interval length evaluation [J]. Tunnelling and Underground Space Technology, 2018, 81: 336–357. DOI: https://doi.org/10.1016/j.tust.2018.07.017.

MA Hong-su, GONG Qiu-ming, WANG Ju, et al. Linear cutting tests on effect of confining stress on rock fragmentation by TBM cutter [J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(2): 346–355. DOI: https://doi.org/10.13722/j.cnki.jrme.2014.0926. (in Chinese)

HUANG Zheng, ZHU Shu-yun. Sensitivity analysis of influencing factors of overburden movement based on orthogonal design [J]. Chinese Journal of Underground Space and Engineering, 2013, 9(1): 106–112. (in Chinese)

MU Wen-qiang, LI Lian-chong, YANG Tian-hong, et al. Numerical calculation and multi-factor analysis of slurry diffusion in an inclined geological fracture [J]. Hydrogeology Journal, 2020, 28(3): 1107–1124. DOI: https://doi.org/10.1007/s10040-019-02103-y.

CHANG S H, CHOI S W, BAE G J, et al. Performance prediction of TBM disc cutting on granitic rock by the linear cutting test [J]. Tunnelling and Underground Space Technology, 2006, 21(3, 4): 271. DOI: https://doi.org/10.1016/j.tust.2005.12.131.

JIN Da-long, SHEN Zhi-chao, YUAN Da-jun. Effect of spatial variability on disc cutters failure during TBM tunneling in hard rock [J]. Rock Mechanics and Rock Engineering, 2020, 53(10): 4609–4621. DOI: https://doi.org/10.1007/s00603-020-02192-2. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

Project(51979156) supported by the National Natural Science Foundation of China; Project(tsqn202103087) supported by the Young Taishan Scholars, China; Project(2019KJG015) supported by the Youth Innovation Technology Project of Higher School in Shandong Province, China

Contributors

LI Xiao-jing proposed this concept and method, and edited and revised the manuscript. ZHANG Hua-ken arranged the data, simulated the software and wrote the first draft. BAI Yi-fan and ZHANG Xiang-yang used the software to establish the numerical model. The results were verified and analyzed by LI Xiao-jing and ZHANG Hua-ken. All authors responded to reviewers’ comments and revised the final version.

Conflict of interest

LI Xiao-jing, ZHANG hua-ken, BAI Yi-fan and ZHANG Xiang-yang stated that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Li, Xj., Zhang, Hk., Bai, Yf. et al. Factor analysis and numerical simulation of rock breaking efficiency of TBM deep rock mass based on orthogonal design. J. Cent. South Univ. 29, 1345–1362 (2022). https://doi.org/10.1007/s11771-022-4994-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-4994-9