Abstract

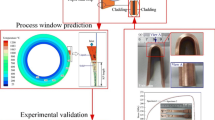

Unequal diameter twin-roll casting (UDTRC) can improve the formability, surface conditions, and production efficiency during the fabrication of clad strips. Using Fluent software, a numerical simulation is used to study the asymmetric heat transfer characteristics of Cu/Al clad strips fabricated by UDTRC. The effects of roller velocity ratio, Cu strip thickness, and inclination angle on the kissing point position, as well as the entire temperature distribution are obtained. The heat transfer model is established, and the mechanism is discussed. The Cu strip and rollers are found to be the main causes of asymmetric heat transfer, indicating that the roller velocity ratio changes the liquid zone proportion in the molten pool. The Cu strip thickness determines the heat absorption capacity and the variations in thermal resistance between the molten Al and the big roller. The inclination angle of the small roller changes the cooling time of big roller to molten Al. Moreover, the microstructure of Al cladding under different roller velocity ratios is examined. The results show significant grain refinement caused by the shear strain along the thickness direction of Al cladding and the intense heat transfer at the moment of contact between the metal Al cladding and Cu strip.

摘要

双辊异径铸轧工艺可提高带材成形性能、表面质量和生产效率. 基于Fluent软件对采用双辊异 径铸轧工艺制备Cu/Al 复合板过程中非对称传热特性进行数值模拟分析, 得到辊速比、铜带厚度及倾 角对凝固点位置和温度场的影响, 建立传热模型, 并探讨传热机理. 结果表明铜带与铸轧辊是造成非 对称传热的主要原因, 其中辊速度比可改变熔池中液相区占比, 铜带厚度决定了冷却速率及铝带和大 铸轧辊间的热阻, 小铸轧辊倾角影响熔融铝的冷却时间. 此外, 获得的不同辊速比时铝带的微观组织 结构表明, 沿铝带厚度方向剪切应变以及铝液与铜带接触瞬时强冷却使晶粒得到细化.

Similar content being viewed by others

References

KUMAI S, TAKAYAMA Y, NAKAMURA R, et al. Application of vertical-type high-speed twin-roll casting for up-grade recycling and clad sheets fabrication of aluminum alloys [J]. Materials Science Forum, 2016, 877: 56–61. DOI: https://doi.org/10.4028/www.scientific.net/msf.877.56.

CHEN Gang, LI Jin-tao, XU Guang-ming. Bonding process and interfacial reaction in horizontal twin-roll casting of steel/aluminum clad sheet [J]. Journal of Materials Processing Technology, 2017, 246: 1–12. DOI: https://doi.org/10.1016/j.jmatprotec.2017.03.003.

JI Ce, HUANG Hua-gui. A review of the twin-roll casting process for complex section products [J]. ISIJ International, 2020, 60(10): 2165–2175. DOI: https://doi.org/10.2355/isijinternational.isijint-2020-149.

LEE D H, KIM J S, SONG H, et al. Tensile property improvement in Ti/Al clad sheets fabricated by twin-roll casting and annealing [J]. Metals and Materials International, 2017, 23(4): 805–812. DOI: https://doi.org/10.1007/s12540-017-6869-4.

HUANG H G, CHEN P, JI C. Solid-liquid cast-rolling bonding (SLCRB) and annealing of Ti/Al cladding strip [J]. Materials & Design, 2017, 118: 233–244. DOI: https://doi.org/10.1016/j.matdes.2017.01.042.

HUANG Hua-gui, DONG Yi-kang, YAN Meng, et al. Evolution of bonding interface in solid-liquid cast-rolling bonding of Cu/Al clad strip [J]. Transactions of Nonferrous Metals Society of China, 2017, 27(5): 1019–1025. DOI: https://doi.org/10.1016/S1003-6326(17)60119-5.

LIU Guo-ping, WANG Qu-dong, ZHANG Li, et al. Effect of cooling rate on the microstructure and mechanical properties of Cu/Al bimetal fabricated by compound casting [J]. Metallurgical and Materials Transactions A, 2018, 49(2): 661–672. DOI: https://doi.org/10.1007/s11661-017-4427-9.

LI Xiao-bing, ZU Guo-yin, WANG Ping. Interface strengthening of laminated composite produced by asymmetrical roll bonding [J]. Materials Science and Engineering A, 2013, 562: 96–100. DOI: https://doi.org/10.1016/j.msea.2012.11.028.

ZHANG Jian-yu, YAO Jin-jin, ZENG Xiang-yong, et al. Research progress of copper cladding aluminum composites [J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1275–1284. (in Chinese)

WANG De, ZHOU Cheng. A top side-pouring twin-roll caster for metals strips [J]. Journal of Materials Processing Technology, 2014, 214(4): 916–924. DOI: https://doi.org/10.1016/j.jmatprotec.2013.12.001.

NAKAMURA R, ASAI T, WATARI H, et al. Casting of aluminum alloy bar by semisolid roll casting [J]. Solid State Phenomena, 2008, 141–143: 295–300. DOI: https://doi.org/10.4028/www.scientific.net/ssp.141-143.295.

HAGA T, INUI H, WATARI H, et al. Casting of Al-Si hypereutectic aluminum alloy strip using an unequal diameter twin roll caster [J]. Journal of Materials Processing Technology, 2007, 191(1–3): 238–241. DOI: https://doi.org/10.1016/j.jmatprotec.2007.03.012.

WANG De, ZHOU Cheng, XU Guo-jin, et al. Heat transfer behavior of top side-pouring twin-roll casting [J]. Journal of Materials Processing Technology, 2014, 214(6): 1275–1284. DOI: https://doi.org/10.1016/j.jmatprotec.2014.01.009.

HUANG Hua-gui, JI Ce, DONG Yi-kang, et al. Thermal-flow coupled numerical simulation and experimental research on bonding mechanism of Cu/Al composite strip by solid-liquid cast-rolling [J]. The Chinese Journal of Nonferrous Metals, 2016, 26(3): 623–629. DOI: https://doi.org/10.19476/j.ysxb.1004.0609.2016.03.018. (in Chinese)

JI Ce, HUANG Hua-gui, ZHANG Jun-peng, et al. Influence of the substrate strip on the asymmetric heat transfer of twin-roll casting for fabricating bimetallic clad strips [J]. Applied Thermal Engineering, 2019, 158: 113818. DOI: https://doi.org/10.1016/j.applthermaleng.2019.113818.

PARK S S, BAE G T, KANG D H, et al. Microstructure and tensile properties of twin-roll cast Mg-Zn-Mn-Al alloys [J]. Scripta Materialia, 2007, 57(9): 793–796. DOI: https://doi.org/10.1016/j.scriptamat.2007.07.013.

JI Ce, HUANG Hua-gui, ZHANG Xu, et al. Numerical and experimental research on fluid flow, solidification, and bonding strength during the twin-roll casting of Cu/invar/Cu clad strips [J]. Metallurgical and Materials Transactions B, 2020, 51(4): 1617–1631. DOI: https://doi.org/10.1007/s11663-020-01854-4.

STOLBCHENKO M, GRYDIN O, SAMSONENKO A, et al. Numerical analysis of the twin-roll casting of thin aluminium-steel clad strips [J]. Forschung Im Ingenieurwesen, 2014, 78(3, 4): 121–130. DOI: https://doi.org/10.1007/s10010-014-0182-x.

LEE Y S, KIM H W, CHO J H. Process parameters and roll separation force in horizontal twin roll casting of aluminum alloys [J]. Journal of Materials Processing Technology, 2015, 218: 48–56. DOI: https://doi.org/10.1016/j.jmatprotec.2014.11.031.

ZHAO Hu, HE Liang-ju, LI Pei-jie. Microstructure of asymmetric twin-roll cast AZ31 magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(11): 2372–2377. DOI: https://doi.org/10.1016/S1003-6326(11)61022-4.

GRYDIN O, STOLBCHENKO M, BAUER M, et al. Asymmetric twin-roll casting of an Al-Mg-Si-alloy [J]. Materials Science Forum, 2018, 918: 48–53. DOI: https://doi.org/10.4028/www.scientific.net/msf.918.48.

PARK J J. Numerical analyses of cladding processes by twin-roll casting: Mg-AZ31 with aluminum alloys [J]. International Journal of Heat and Mass Transfer, 2016, 93: 491–499. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2015.10.002.

VOLLER V R, PRAKASH C. A fixed grid numerical modelling methodology for convection-diffusion mushy region phase-change problems [J]. International Journal of Heat and Mass Transfer, 1987, 30(8): 1709–1719. DOI: https://doi.org/10.1016/0017-9310(87)90317-6.

PARK J J. Finite-element analysis of severe plastic deformation in differential-speed rolling [J]. Computational Materials Science, 2015, 100: 61–66. DOI: https://doi.org/10.1016/j.commatsci.2014.09.010.

WANG Z J, ZHAI L, MA M, et al. Microstructure, texture and mechanical properties of Al/Al laminated composites fabricated by hot rolling [J]. Materials Science and Engineering A, 2015, 644: 194–203. DOI: https://doi.org/10.1016/j.msea.2015.07.035.

ZHANG Jun-peng, HUANG Hua-gui, ZHAO Ri-dong, et al. Cast-rolling force model in solid-liquid cast-rolling bonding (SLCRB) process for fabricating bimetal clad strips [J]. Transactions of Nonferrous Metals Society of China, 2021, 31(3): 626–635. DOI: https://doi.org/10.1016/S1003-6326(21)65524-3.

BEAUSIR B, BISWAS S, KIM D I, et al. Analysis of microstructure and texture evolution in pure magnesium during symmetric and asymmetric rolling [J]. Acta Materialia, 2009, 57(17): 5061–5077. DOI: https://doi.org/10.1016/j.actamat.2009.07.008.

LIU Rui-feng, WANG Wen-xian, CHEN Hong-sheng. Synthesis of nano- to micrometer-sized B4C particle-reinforced aluminum matrix composites via powder metallurgy and subsequent heat treatment [J]. Journal of Central South University, 2021, 28(8): 2295–2306. DOI: https://doi.org/10.1007/s11771-021-4770-2.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

Project(51974278) supported by the National Natural Science Foundation of China; Project(E2018203446) supported by the Natural Science Foundation of Hebei Province Distinguished Young Fund Project, China; Project(2018YFA0707303) supported by the National Key Research and Development Project of China

Contributors

HUANG Hua-gui provided the funding support, ZHANG Jun-peng conducted the conception, experiment and edited the draft of manuscript, and JI Ce reviewed the manuscript.

Conflict of interest

HUANG Hua-gui, ZHANG Jun-peng, and JI Ce declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Huang, Hg., Zhang, Jp. & Ji, C. Heat transfer analysis and experimental study of unequal diameter twin-roll casting process for fabricating Cu/Al clad strips. J. Cent. South Univ. 29, 1133–1146 (2022). https://doi.org/10.1007/s11771-022-4990-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-4990-0

Key words

- unequal diameter twin-roll casting

- Cu/Al clad strips

- asymmetric heat transfer

- thermal-fluid coupled

- microstructure