Abstract

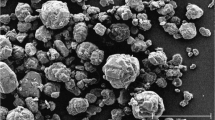

Fibrous activated alumina is widely applied in catalysts, adsorbents, and composite materials. This work presents a green approach in preparing the fibrous activated Al2O3 with high purity and specific surface area through multistep phase transformation of aluminum-bearing substances using intermediate dawsonite as a template. Thermodynamic calculations and experimental results show that increasing the concentration of Na2CO3 and (NH4)2CO3 is remarkably beneficial to the formation of dawsonite and ammonium aluminum carbonate hydroxide, respectively. Based on determination of dissolution and precipitation mechanism, the ultrafine granular gibbsite is converted to the uniform fibrous dawsonite with a ratio of length to diameter over 50, and the fibrous dawsonite changes into the long fibrous ammonium aluminum carbonate hydroxide with a ratio of length to diameter is about 80 in above 70 g/L (NH4)2CO3 solution. Furthermore, the activated alumina remains fibrous morphology after roasting ammonium aluminum carbonate hydroxide at a slow heating rate, plentiful open mesopore and weak aggregation of particles, which contributes to the high specific surface area of 159.37 m2/g at 1273 K for the activated alumina. The complete transformation of dawsonite to ammonium aluminum carbonate hydroxide and high specific surface area contribute to the purity of the activated fibrous alumina above 99.9% with low Na and Fe content.

摘要

纤维状活性氧化铝被广泛应用于催化剂、吸附剂和复合材料等领域. 本文提出了一种绿色方 法, 以中间体丝钠铝石为模板, 通过含铝物相的多步相变制备具有高纯度和高比表面积的纤维状活性 氧化铝. 热力学计算和实验结果表明, 提高Na2CO3和(NH4)2CO3的浓度分别有利于丝钠铝石和碳酸铝 铵的形成. 根据溶解和沉淀机理, 超细粒状氢氧化铝可以转变为长径比大于50 的纤维状丝钠铝石, 而 纤维状丝钠铝石在70 g/L 以上的(NH4)2CO3 溶液中又可以转变为长径比约80 的纤维状碳酸铝铵. 此外, 纤维状碳酸铝铵经缓慢加热分解后得到的活性氧化铝仍可以保持纤维状形态, 且大量开放的介孔结构 和颗粒间的弱聚集使活性氧化铝在1273 K的焙烧温度下仍具有159.37 m2/g 的高比表面积. 丝钠铝石完 全转化为碳酸铝铵和高比表面积使纤维状活性氧化铝的纯度超过99.9%, 且Na和Fe含量较低.

Similar content being viewed by others

References

CHEN An-nan, WU Jia-min, LIU Yu-xuan, et al. Fabrication of porous fibrous alumina ceramics by direct coagulation casting combined with 3D printing [J]. Ceramics International, 2018, 44(5): 4845–4852. DOI: https://doi.org/10.1016/j.ceramint.2017.12.073.

WANG Yan, LI Wei, XIA Yu-guo, et al. Electrospun flexible self-standing γ-alumina fibrous membranes and their potential as high-efficiency fine particulate filtration media [J]. J Mater Chem A, 2014, 2(36): 15124–15131. DOI: https://doi.org/10.1039/c4ta01770f.

COOPER C A, LIN Y S. Microstructural and gas separation properties of CVD modified mesoporous γ-alumina membranes [J]. Journal of Membrane Science, 2002, 195(1): 35–50. DOI: https://doi.org/10.1016/S0376-7388(01)00508-7.

POTEMKIN D I, AGHAYAN M, USKOV S I, et al. Fibrous alumina-based Ni-CeO2 catalyst: Synthesis, structure and properties in propane pre-reforming [J]. Materials Letters, 2018, 215: 35–37. DOI: https://doi.org/10.1016/j.matlet.2017.12.039.

CHEN Li-juan, YAN Jing-qing, TONG Zhan-xin, et al. Nanofiber-like mesoporous alumina supported palladium nanoparticles as a highly active catalyst for base-free oxidation of benzyl alcohol [J]. Microporous and Mesoporous Materials, 2018, 266: 126–131. DOI: https://doi.org/10.1016/j.micromeso.2018.02.037.

ZANG Wen-jie, GUO Feng, LIU Jia-chen, et al. Lightweight alumina based fibrous ceramics with different high temperature binder [J]. Ceramics International, 2016, 42(8): 10310–10316. DOI: https://doi.org/10.1016/j.ceramint.2016.03.170.

TORRES L M F C, BRAGA N A, GOMES I P, et al. Nanobiostructure of fibrous-like alumina functionalized with an analog of the BP100 peptide: Synthesis, characterization and biological applications [J]. Colloids and Surfaces B: Biointerfaces, 2018, 163: 275–283. DOI: https://doi.org/10.1016/j.colsurfb.2018.01.001.

SRIDHAR R, SUNDARRAJAN S, VENUGOPAL J R, et al. Electrospun inorganic and polymer composite nanofibers for biomedical applications [J]. Journal of Biomaterials Science Polymer Edition, 2013, 24(4): 365–385. DOI: https://doi.org/10.1080/09205063.2012.690711.

MEDVECKÁ V, KOVÁČIK D, STUPAVSKÁ M, et al. Preparation and characterization of alumina submicron fibers by plasma assisted calcination [J]. Ceramics International, 2020, 46(14): 22774–22780. DOI: https://doi.org/10.1016/j.ceramint.2020.06.044.

ABDULLAH N, RAHMAN M A, DZARFAN OTHMAN M H, et al. Preparation, characterizations and performance evaluations of alumina hollow fiber membrane incorporated with UiO-66 particles for humic acid removal [J]. Journal of Membrane Science, 2018, 563: 162–174. DOI: https://doi.org/10.1016/j.memsci.2018.05.059.

YANG Dong-jiang, PAUL B, XU Wu-jun, et al. Alumina nanofibers grafted with functional groups: A new design in efficient sorbents for removal of toxic contaminants from water [J]. Water Research, 2010, 44(3): 741–750. DOI: https://doi.org/10.1016/j.watres.2009.10.014.

XU Xiang-yu, YU Qing-quan, LV Zhi, et al. Synthesis of high-surface-area rod-like alumina materials with enhanced Cr(VI) removal efficiency [J]. Microporous and Mesoporous Materials, 2018, 262: 140–147. DOI: https://doi.org/10.1016/j.micromeso.2016.12.002.

SONG Xiao-lan, QU Peng, YANG Hai-pin, et al. Synthesis of γ-Al2O3 nanoparticles by chemical precipitation method [J]. Journal of South University of Technology, 2005, 12(5): 536–541. DOI: https://doi.org/10.1007/s11771-005-0118-6.

PATRA A K, DUTTA A, BHAUMIK A. Self-assembled mesoporous γ-Al2O3 spherical nanoparticles and their efficiency for the removal of arsenic from water [J]. Journal of Hazardous Materials, 2012, 201–202: 170–177. DOI: https://doi.org/10.1016/j.jhazmat.2011.11.056.

SHIVAPRASAD P, SINGH P K, SAHARAN V K, et al. Synthesis of nano alumina for defluoridation of drinking water [J]. Nano-Structures & Nano-Objects, 2018, 13: 109–120. DOI: https://doi.org/10.1016/j.nanoso.2018.01.001.

ROQUE-RUIZ J H, MEDELLÍN-CASTILLO N A, REYES-LÓPEZ S Y. Fabrication of α-alumina fibers by sol-gel and electrospinning of aluminum nitrate precursor solutions [J]. Results in Physics, 2019, 12: 193–204. DOI: https://doi.org/10.1016/j.rinp.2018.11.068.

JING Cheng-bin, XU Xin-guang, HOU Jin-xia. Synthesis of sub-micro-sized solid alpha alumina fibers with smooth surfaces by sol–gel method [J]. Journal of Sol-Gel Science and Technology, 2008, 45(1): 109–113. DOI: https://doi.org/10.1007/s10971-007-1644-5.

LEE H C, KIM H J, CHUNG S H, et al. Synthesis of unidirectional alumina nanostructures without added organic solvents [J]. Journal of the American Chemical Society, 2003, 125(10): 2882–2883. DOI: https://doi.org/10.1021/ja029494l.

QU Li-hong, HE Chang-qing, YANG Yue, et al. Hydrothermal synthesis of alumina nanotubes templated by anionic surfactant [J]. Materials Letters, 2005, 59(29, 30): 4034–4037. DOI: https://doi.org/10.1016/j.matlet.2005.07.059.

ZHU Zhen-feng, LIU Hui, SUN Hong-jun, et al. PEG-directed hydrothermal synthesis of multilayered alumina microfibers with mesoporous structures [J]. Microporous and Mesoporous Materials, 2009, 123(1–3): 39–44. DOI: https://doi.org/10.1016/j.micromeso.2009.03.028.

KENAWY S H, HASSAN M L. Synthesis and characterization high purity alumina nanorods by a novel and simple method using nanocellulose aerogel template [J]. Heliyon, 2019, 5(6): e01816. DOI: https://doi.org/10.1016/j.heliyon.2019.e01816.

ALI M, MUJTABA-UL-HASSAN S, AHMAD J, et al. Fabrication of PEGylated Porous Alumina Whiskers (PAW) for drug delivery applications [J]. Materials Letters, 2019, 241: 23–26. DOI: https://doi.org/10.1016/j.matlet.2019.01.044.

DABBAGH H A, SHAHRAKI M. Mesoporous nano rod-like γ-alumina synthesis using phenol-formaldehyde resin as a template [J]. Microporous and Mesoporous Materials, 2013, 175: 8–15. DOI: https://doi.org/10.1016/j.micromeso.2013.03.011.

WANG Wei-li, BI Jian-qiang, QI Yong-qiu, et al. Preparation of micrometer-sized α-Al2O3 platelets by thermal decomposition of AACH [J]. Powder Technology, 2010, 201(3): 273–276. DOI: https://doi.org/10.1016/j.powtec.2010.04.010.

LI Yan-hui, LI Liang-long, PENG Cheng, et al. A decomposition route for synthesis of Al2O3 crystal and its applications as thermal conductivity filler [J]. Journal of the American Ceramic Society, 2014, 97(3): 695–699. DOI: https://doi.org/10.1111/jace.12848.

MORINAGA K, TORIKAI T, NAKAGAWA K, et al. Fabrication of fine α-alumina powders by thermal decomposition of ammonium aluminum carbonate hydroxide (AACH) [J]. Acta Materialia, 2000, 48(18, 19): 4735–4741. DOI: https://doi.org/10.1016/S1359-6454(00)00265-2.

STOICA G, PωREZ-RAMÍREZ J. Reforming dawsonite by memory effect of AACH-derived aluminas [J]. Chemistry of Materials, 2007, 19(19): 4783–4790. DOI: https://doi.org/10.1021/cm071351g.

STOICA G, ABELLÓ S, PωREZ-RAMÍREZ J. Nadawsonite derived aluminates for DMC production by transesterification of ethylene carbonate [J]. Applied Catalysis A: General, 2009, 365(2): 252–260. DOI: https://doi.org/10.1016/j.apcata.2009.06.022.

ABDULLAH M, MEHMOOD M, AHMAD J. Single step hydrothermal synthesis of 3D urchin like structures of AACH and aluminum oxide with thin nano-spikes [J]. Ceramics International, 2012, 38(5): 3741–3745. DOI: https://doi.org/10.1016/j.ceramint.2012.01.019.

MIRZAJANY R, ALIZADEH M, RAHIMIPOUR M R, et al. Seed-assisted hydrothermally synthesized AACH as the alumina precursors [J]. Materials Chemistry and Physics, 2019, 221: 188–196. DOI: https://doi.org/10.1016/j.matchemphys.2018.08.083.

MEHBOOB S, MEHMOOD M, AHMED M, et al. Terahertz time domain spectroscopy of amorphous and crystalline aluminum oxide nanostructures synthesized by thermal decomposition of AACH [J]. Materials Chemistry and Physics, 2017, 191: 62–69. DOI: https://doi.org/10.1016/j.matchemphys.2017.01.030.

ZHU Zhen-feng, SUN Hong-jun, LIU Hui, et al. PEG-directed hydrothermal synthesis of alumina nanorods with mesoporous structure via AACH nanorod precursors [J]. Journal of Materials Science, 2010, 45(1): 46–50. DOI: https://doi.org/10.1007/s10853-009-3886-9.

WANG Fang, ZHU Jian-feng, LIU Hui. Urea controlled hydrothermal synthesis of ammonium aluminum carbonate hydroxide rods [J]. AIP Advances, 2018, 8(3): 035103. DOI: https://doi.org/10.1063/1.5018826.

LI Jie, LI Wu, NAI Xue-ying, et al. Synthesis and formation of alumina whiskers from hydrothermal solution [J]. Journal of Materials Science, 2010, 45(1): 177–181. DOI: https://doi.org/10.1007/s10853-009-3913-x.

AHMAD J, TARIQ M I, AHMAD R, et al. Formation of porous α-alumina from ammonium aluminum carbonate hydroxide whiskers [J]. Ceramics International, 2019, 45(4): 4645–4652. DOI: https://doi.org/10.1016/j.ceramint.2018.11.154.

WU Guo-yu, LIU Gui-hua, LI Xiao-bin, et al. A green approach of preparation of fine active alumina with high specific surface area from sodium aluminate solution [J]. RSC Advances, 2019, 9(10): 5628–5638. DOI: https://doi.org/10.1039/c8ra09853k.

LI Xiao-bin, LIU Nan, ZHOU Qiu-sheng, et al. Dawsonite preparation by deep carbonation decomposition of spent liquor from carbonation of sodium aluminate solutions [J]. Journal of Central South University (Science and Technology), 2016, 47(1): 20–25. (in Chinese)

LI Guang-ci, LIU Yun-qi, GUAN Li-li, et al. Meso/macroporous γ-Al2O3 fabricated by thermal decomposition of nanorods ammonium aluminium carbonate hydroxide [J]. Materials Research Bulletin, 2012, 47(4): 1073–1079. DOI: https://doi.org/10.1016/j.materresbull.2011.12.026.

WANG P, ZHAO Z D, BI L W, et al. Synthesis of mesoporous alumina microfibres by ammonium carbonate precipitation [J]. Materials Research Innovations, 2012, 16(2): 121–125. DOI: https://doi.org/10.1179/1433075x11y.0000000033.

ZHANG Xiang-feng, WEN Zhao-yin, GU Zhong-hua, et al. Hydrothermal synthesis and thermodynamic analysis of dawsonite-type compounds [J]. Journal of Solid State Chemistry, 2004, 177(3): 849–855. DOI: https://doi.org/10.1016/j.jssc.2003.09.019.

STOICA G, PÉREZ-RAMÍREZ J. Stability and interconversion of synthetic dawsonites in aqueous media [J]. Geochimica et Cosmochimica Acta, 2010, 74(24): 7048–7058. DOI: https://doi.org/10.1016/j.gca.2010.09.013.

XU Xiang-ming, LI Xiao-bin, ZHOU Qiu-sheng, et al. Equilibrium WO3 concentration in the Ca2+- (NH4)2CO3-(NH4)2WO4-NH3-H2O system [J]. Chemical Engineering Science, 2019, 206: 156–163. DOI: https://doi.org/10.1016/j.ces.2019.05.038.

SIMOES M C, HUGHES K J, INGHAM D B, et al. Predicting speciation of ammonia, monoethanolamine, and diethanolamine using only ionic radius and ionic charge [J]. Industrial & Engineering Chemistry Research, 2018, 57(6): 2346–2352. DOI: https://doi.org/10.1021/acs.iecr.7b04250.

BÉNÉZETH P, PALMER D A, ANOVITZ L M, et al. Dawsonite synthesis and reevaluation of its thermodynamic properties from solubility measurements: Implications for mineral trapping of CO2 [J]. Geochimica et Cosmochimica Acta, 2007, 71(18): 4438–4455. DOI: https://doi.org/10.1016/j.gca.2007.07.003.

WAGMAN D D, EVANS W H, PARKER V B, et al. Erratum: The NBS tables of chemical thermodynamic properties. Selected values for inorganic and C1 and C2 organic substances in SI units[J. Phys. Chem. Ref. Data 11, Suppl. 2 (1982)] [J]. Journal of Physical and Chemical Reference Data, 1989, 18(4): 1807–1812. DOI: https://doi.org/10.1063/1.555845.

HEMINGWAY B S, ROBIE R A, KITTRICK J A. Revised values for the Gibbs free energy of formation of [Al(OH)4aq−], diaspore, boehmite and bayerite at 298.15 K and 1 bar, the thermodynamic properties of kaolinite to 800 K and 1 bar, and the heats of solution of several gibbsite samples [J]. Geochimica et Cosmochimica Acta, 1978, 42(10): 1533–1543. DOI: https://doi.org/10.1016/0016-7037(78)90024-8.

LI Xiao-bin, YAN Li, ZHAO Dong-feng, et al. Relationship between Al(OH)3 solubility and particle size in synthetic Bayer liquors [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(5): 1472–1479. DOI: https://doi.org/10.1016/S1003-6326(13)62619-9.

BAZYARI A, MORTAZAVI Y, KHODADADI A A, et al. Effects of alumina phases as nickel supports on deep reactive adsorption of (4, 6-dimethyl) dibenzothiophene: Comparison between γ, δ, and θ-alumina [J]. Applied Catalysis B: Environmental, 2016, 180: 312–323. DOI: https://doi.org/10.1016/j.apcatb.2015.06.025.

TIAN Qing-bo. The influences of fluorides on the transformation of α-alumina crystals [J]. Ceramics-Silikaty, 2017: 357–366. DOI: https://doi.org/10.13168/cs.2017.0035.

LAFFICHER R, DIGNE M, SALVATORI F, et al. Ammonium aluminium carbonate hydroxide NH4Al(OH)2CO3 as an alternative route for alumina preparation: Comparison with the classical boehmite precursor [J]. Powder Technology, 2017, 320: 565–573. DOI: https://doi.org/10.1016/j.powtec.2017.07.080.

FU Xiu-feng, XU Ben-jun, HUANG Cai-juan. Preparation of high purity alumina technology overview [J]. Advanced Materials Research, 2013, 734–737: 2496–2500. DOI: https://doi.org/10.4028/www.scientific.net/amr.734-737.2496.

PITZER K S, MAYORGA G. Thermodynamics of electrolytes. II. Activity and osmotic coefficients for strong electrolytes with one or both ions univalent [J]. The Journal of Physical Chemistry, 1973, 77(19): 2300–2308. DOI: https://doi.org/10.1021/j100638a009.

KAWAZUISHI K, PRAUSNITZ J M. Correlation of vapor-liquid equilibria for the system ammonia-carbon dioxide-water [J]. Industrial & Engineering Chemistry Research, 1987, 26(7): 1482–1485. DOI: https://doi.org/10.1021/ie00067a036.

Lange’s handbook of chemistry [J]. Journal of the American Society for Naval Engineers, 1941, 53(4): 904. DOI: https://doi.org/10.1111/j.1559-3584.1941.tb01566.x.

RUMPF D I B. Thermochemical data of pure substances [J]. Veterinary Immunology and Immunopathology, 1997, 55(4): 359–360. DOI: https://doi.org/10.1016/s0165-2427(96)05632-2.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

Project(51874372) supported by the National Natural Science Foundation of China

Contributors

TANG Jie and LIU Gui-hua conducted experiment and wrote the paper. QI Tian-gui revised the manuscript, ZHOU Qiu-sheng and PENG Zhi-hong provided some helpful advices. LI Xiao-bin also revised the manuscript. All authors replied to reviewers’ comments and revised the final version.

Conflict of interest

TANG Jie, LIU Gui-hua, QI Tian-gui, ZHOU Qiu-sheng, PENG Zhi-hong and LI Xiao-bin declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Tang, J., Liu, Gh., Qi, Tg. et al. Fibrous activated alumina prepared through phase transformation using dawsonite as a template. J. Cent. South Univ. 29, 1147–1160 (2022). https://doi.org/10.1007/s11771-022-4987-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-4987-8