Abstract

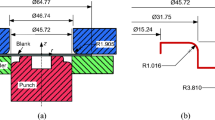

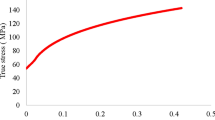

In this study, a novel punch toolset was developed to investigate the hot stamping of AA6082-T4 sheet. The effect of the process parameters, including forming temperature, punching velocity, friction coefficient, and blank holder force (BHF) on formability was quantified using Taguchi design, analysis of variance (ANOVA) and mathematical statistics. The finite element (FE) model has been established in software Pamstamp for simulation and analysis of their effects on the minimum thickness and thickness variation of the hot-stamped component. The major factors influencing the minimum thickness of the hot-stamped part has been found to be BHF and friction coefficient with influence significance of 35.3% and 34.88%, respectively. Additionally, punch velocity and BHF affect the thickness deviation significantly with influence significance of 40.43% and 35.42%, respectively. Furthermore, a serious thinning occurs on the punch corner region of the hot-stamped cup when the BHF is larger than 2.4 kN. The thickness deviation of the hot-formed cup has been found to be firstly decreased and then increased with the increase of punch velocity. Low friction coefficient between punch and blank led to crack at bottom centre of the cup. Moreover, different type, phenomenon and mechanism of defects occurring during hot stamping process, such as crack and wrinkling, were discussed. The crack mode was dimple-dominated ductile fracture, which was induced by micro-void nucleation, growth and coalescence.

摘要

通过新设计的铝合金热冲压装置进行AA6082-T4铝合金热冲压研究. 研究的工艺参数包括成形温度、 冲压速度、 摩擦系数和压边力. 通过Taguchi实验设计、 方差分析和数理统计相结合的方法量化了工艺参数对成形性的影响程度. 采用有限元软件Pamstamp建立了仿真模型, 用来分析工艺参数对最小厚度和厚度均匀性的影响. 通过分析可知, 压边力和摩擦系数对零件厚度最小值的影响最显著, 影响程度分别为35.3%和34.88%. 冲压速度和压边力对厚度均匀性的影响最显著, 影响程度分别为40.43%和35.42%. 当压边力超过2.4 kN时, 在热冲压零件凸模圆角处会产生严重的减薄. 随着冲压速度的增加, 热冲压零件的厚度均匀性先下降后上升. 板料与凸模之间过低的摩擦系数会导致杯形件底部中心发生破裂. 同时研究了铝合金热冲压零件的缺陷, 比如破裂和起皱的种类、 现象和机理. 断裂形式主要为以韧窝为主的韧性断裂, 主要由微孔洞形核, 长大和聚合导致.

Similar content being viewed by others

References

ZHANG Xin, XU Hong, CHEN Tong, et al. Forming properties and microstructure of Al−Cu alloy prepared by liquid-die forging [J]. Journal of Central South University, 2022, 29(1): 60–79. DOI: https://doi.org/10.1007/s11771-022-4928-6.

JIAO Yi-nan, ZHANG Yi-fan, MA Shi-qing, et al. Effects of microstructural heterogeneity on fatigue properties of cast aluminum alloys [J]. Journal of Central South University, 2020, 27(3): 674–697. DOI: https://doi.org/10.1007/s11771-020-4323-0.

MA Wen-yu, WANG Bao-yu, BIAN Jian-hua, et al. A new damage constitutive model for thermal deformation of AA6111 sheet [J]. Metallurgical and Materials Transactions A, 2015, 46(6): 2748–2757. DOI: https://doi.org/10.1007/s11661-015-2823-6.

PASSARINI F, CIACCI L, SANTINI A, et al. Aluminium flows in vehicles: Enhancing the recovery at end-of-life [J]. Journal of Material Cycles and Waste Management, 2014, 16(1): 39–45. DOI: https://doi.org/10.1007/s10163-013-0175-0.

VOVK V, HOFFMANN R, YASEN A. Method of welding and spinning combination for complex aluminium alloys lightweight components [J]. Materials Today: Proceedings, 2015, 2: S162–S168. DOI: https://doi.org/10.1016/j.matpr.2015.05.006.

MOHAMED M S, FOSTER A D, LIN Jian-guo, et al. Investigation of deformation and failure features in hot stamping of AA6082: Experimentation and modelling [J]. International Journal of Machine Tools and Manufacture, 2012, 53(1): 27–38. DOI: https://doi.org/10.1016/j.ijmachtools.2011.07.005.

ZHANG Tao, ZHANG Shao-hang, LI Lei, et al. Modified constitutive model and workability of 7055 aluminium alloy in hot plastic compression [J]. Journal of Central South University, 2019, 26(11): 2930–2942. DOI: https://doi.org/10.1007/s11771-019-4225-1.

MA Wen-yu, WANG Bao-yu, FU Lei, et al. Influence of process parameters on deep drawing of AA6111 aluminum alloy at elevated temperatures [J]. Journal of Central South University, 2015, 22(4): 1167–1174. DOI: https://doi.org/10.1007/s11771-015-2630-7.

KIM H S, KOÇ M, NI Jun. Development of an analytical model for warm deep drawing of aluminum alloys [J]. Journal of Materials Processing Technology, 2008, 197(1–3): 393–407. DOI: https://doi.org/10.1016/j.jmatprotec.2007.06.046.

MA Wen-yu, WANG Bao-yu, FU Lei, et al. Effect of friction coefficient in deep drawing of AA6111 sheet at elevated temperatures [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(7): 2342–2351. DOI: https://doi.org/10.1016/S1003-6326(15)63849-3.

XU Xue-feng, WU Kong-wei, WU Yi-wang, et al. A novel lubrication method for hydroforming of thin-walled aluminum alloy T-shaped tube [J]. The International Journal of Advanced Manufacturing Technology, 2019, 102(5–8): 2265–2273. DOI: https://doi.org/10.1007/s00170-019-03339-4.

BATE P S, RIDLEY N, ZHANG B, et al. Optimisation of the superplastic forming of aluminium alloys [J]. Journal of Materials Processing Technology, 2006, 177(1–3): 91–94. DOI: https://doi.org/10.1016/j.jmatprotec.2006.03.200.

ZHANG Pan, YE Ling-ying, ZHANG Xin-ming, et al. Grain structure and microtexture evolution during superplastic deformation of 5A90 Al−Li alloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2088–2093. DOI: https://doi.org/10.1016/S1003-6326(14)63316-1.

LIN J, DEAN T, GARRETT R, et al. A process in forming high strength and complex-shaped Al-alloy sheet components, WO2008059242 [P]. 2008.

WANG L, STRANGWOOD M, BALINT D, et al. Formability and failure mechanisms of AA2024 under hot forming conditions [J]. Materials Science and Engineering A, 2011, 528(6): 2648–2656. DOI: https://doi.org/10.1016/j.msea.2010.11.084.

el FAKIR O, WANG Li-liang, BALINT D, et al. Numerical study of the solution heat treatment, forming, and in-die quenching (HFQ) process on AA5754 [J]. International Journal of Machine Tools and Manufacture, 2014, 87: 39–48. DOI: https://doi.org/10.1016/j.ijmachtools.2014.07.008.

HARRISON N R, LUCKEY S G. Hot stamping of a B-pillar outer from high strength aluminum sheet AA7075 [J]. SAE International Journal of Materials and Manufacturing, 2014, 7(3): 567–573. DOI: https://doi.org/10.4271/2014-01-0981.

ZHAO Kun-min, REN Da-xin, WANG Bin, et al. Investigation of the interfacial heat transfer coefficient of sheet aluminum alloy 5083 in warm stamping process [J]. International Journal of Heat and Mass Transfer, 2019, 132: 293–300. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2018.11.158.

JAISINGH A, NARASIMHAN K, DATE P P, et al. Sensitivity analysis of a deep drawing process for miniaturized products [J]. Journal of Materials Processing Technology, 2004, 147(3): 321–327. DOI: https://doi.org/10.1016/j.jmatprotec.2003.11.023.

ÖZEK C, ÜNAL E. Optimization and modeling of angular deep drawing process for square cups [J]. Materials and Manufacturing Processes, 2011, 26(9): 1117–1125. DOI: https://doi.org/10.1080/10426914.2010.532526.

DIETER G. Mechanical metallurgy (third edition) [M]. New York: McGraw-Hill Global Education Holdings, 2013.

PADMANABHAN R, OLIVEIRA M C, ALVES J L, et al. Stochastic analysis of a deep drawing process using finite element simulations [J]. International Journal of Material Forming, 2009, 2(1): 347–350. DOI: https://doi.org/10.1007/s12289-009-0565-y.

PADMANABHAN R, OLIVEIRA M C, ALVES J L, et al. Influence of process parameters on the deep drawing of stainless steel [J]. Finite Elements in Analysis and Design, 2007, 43(14): 1062–1067. DOI: https://doi.org/10.1016/j.finel.2007.06.011.

WANG You-gen, HUANG Guang-sheng, LIU Ding-kai, et al. Influence of blank holder type on drawability of 5182-O aluminum sheet at room temperature [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(5): 1251–1258. DOI: https://doi.org/10.1016/S1003-6326(16)64225-5.

ZHOU Jing, WANG Bao-yu, LIN Jian-guo, et al. Forming defects in aluminum alloy hot stamping of side-door impact beam [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(11): 3611–3620. DOI: https://doi.org/10.1016/S1003-6326(14)63506-8.

CHEN F K, HUANG T B, CHANG C K. Deep drawing of square cups with magnesium alloy AZ31 sheets [J]. International Journal of Machine Tools and Manufacture, 2003, 43(15): 1553–1559. DOI: https://doi.org/10.1016/S0890-6955(03)00198-6.

SHAO Zhu-tao, LI Nan, LIN Jian-guo, et al. Formability evaluation for sheet metals under hot stamping conditions by a novel biaxial testing system and a new materials model [J]. International Journal of Mechanical Sciences, 2017, 120: 149–158. DOI: https://doi.org/10.1016/j.ijmecsci.2016.11.022.

DILMEC M, ARAP M. Effect of geometrical and process parameters on coefficient of friction in deep drawing process at the flange and the radius regions [J]. The International Journal of Advanced Manufacturing Technology, 2016, 86(1–4): 747–759. DOI: https://doi.org/10.1007/s00170-015-8225-5.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, Wy., Wang, By., Rong, Q. et al. Influence of process parameters and defect analysis in hot deep drawing process of aluminum alloy AA6082. J. Cent. South Univ. 29, 883–897 (2022). https://doi.org/10.1007/s11771-022-4984-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-4984-y