Abstract

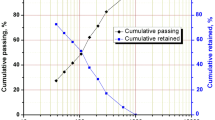

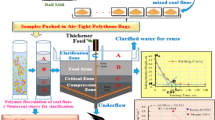

Fine particle flotation has been one of the main problems in many mineral processing plants. The bubble-particle collision rate is very low for fine particles, which reduces flotation efficiency. Also, the existence of slimes is, generally, detrimental to the flotation process, affecting the selectivity and the quality of the concentrates. Besides, it causes an increase in reagents consumption. Hence, in most of processing plants, some of these particles are transmitted to the tailing ponds to reduce the effects of these problems and increase the selectivity of the process. Esfordi phosphate plant in Iran loses more than 30% of its capacity as particles with d80 finer than 30 µm. These fine particles with 15.9% P2O5 content are transferred to tailing dam. Processing of fine particles is very important for phosphate industry from economic and environmental aspects. This study addressed the processing of fine tailings (slimes) from a phosphate ore concentrator via flotation, despite the traditional view that ultrafine particles do not float. Phosphate flotation performances in the presence and absence of nanobubbles (NBs) in both mechanical and column cells were compared according to the metallurgical results of the process. NBs (generated by hydrodynamic cavitation) have interesting and exclusive properties such as high stability, durability and high surface area per volume, leading to increase of their utilization in mining-metallurgy and environmental areas. The results of this study revealed that, in the absence of NBs, a concentrate containing 26.9% P2O5 with a recovery of 29.13% was obtained using mechanical cells in comparison to 31.6% P2O5 with a recovery of 32.74% obtained using column flotation. In the presence of NBs, the recoveries of the concentrate of the mechanical and column flotation increased to 40.49% and 41.26% with 28.47% and 30.43% P2O5 contents, respectively. Comparative study showed that the column flotation was almost more efficient for processing the phosphate ore in the presence of the NBs, and had thicker froth layer compared to the mechanical flotation.

摘要

细粒浮选一直是许多矿物加工厂面临的主要问题之一。由于细颗粒的气泡粒子碰撞概率很低, 因此降低了浮选效率。细粒的存在通常不利于浮选过程, 影响了浮选精矿的选择性和质量, 而且增加 了试剂的消耗量。因此, 在大多数加工厂中, 会将部分颗粒输送到尾矿池中, 以减少这些问题的影 响, 并提高浮选过程的选择性。由于 d80 小于30 µm 的颗粒的存在, 使伊朗的Esfordi 磷酸盐厂损失了至 少30% 的处理能力。将这些P2O5 含量为15.9% 的细颗粒转移到尾矿坝, 从经济和环境两方面来看, 细 颗粒的加工对磷酸盐工业具有重要意义。本文探讨了通过浮选工艺处理磷酸矿选矿厂的细尾矿的问 题, 尽管传统观点认为超细颗粒不可浮选。根据冶金工艺性能结果, 比较了有无纳米气泡(NBs)时, 浮选机和浮选柱两种处理工艺下磷酸盐矿物的浮选行为。由于NBs(由水动力空化作用产生)具有有 趣的和独特的性能, 如高稳定性、耐久性和高比表面积, 提高了其在采矿、冶金和环境领域的应用。 本研究结果表明, 在没有NBs 的情况下, 使用浮选机工艺获得了P2O5 含量为26.9%、回收率为29.13% 的精矿, 而使用浮选柱工艺, 得到的P2O5 含量为31.6%, 回收率, 通过浮选机和浮选柱获得精矿的回收率分别为40.49% 和41.26%, P2O5 含量分别为28.47% 和 30.43%。对比研究表明, 在NBs 存在的情况下, 与浮选机相比, 浮选柱工艺对磷矿的处理效率更高, 泡沫层更厚。

Similar content being viewed by others

References

LAN Zhuo-yue, LAI Zhen-ning, ZHENG Yong-xing, et al. Recovery of Zn, Pb, Fe and Si from a low-grade mining ore by sulfidation roasting-beneficiation-leaching processes [J]. Journal of Central South University, 2020, 27(1): 37–51. DOI: https://doi.org/10.1007/s11771-020-4276-3.

ASGHARI M, VANDGHORBANY O, NAKHAEI F. Relationship among operational parameters, ore characteristics, and product shape properties in an industrial SAG mill [J]. Particulate Science and Technology, 2020, 38(4): 482–493. DOI: https://doi.org/10.1080/02726351.2018.1482977.

YUE Tao, WU Xi-qing, DAI Liang. Effect of magnetic seeding agglomeration on flotation of fine minerals [J]. Journal of Central South University, 2019, 26(1): 75–87. DOI: https://doi.org/10.1007/s11771-019-3983-0.

MIETTINEN T, RALSTON J, FORNASIERO D. The limits of fine particle flotation [J]. Minerals Engineering, 2010, 23(5): 420–437. DOI: https://doi.org/10.1016/j.mineng.2009.12.006.

PETUKHOV V N, SVECHNIKOVA N Y, KUKLINA O V, et al. Improving the flotation of fine coal slurries [J]. Coke and Chemistry, 2020, 63(5): 247–252. DOI: https://doi.org/10.3103/S1068364X2005004X.

FU Jian-gang, CHEN Kai-da, WANG Hui, et al. Recovering molybdenite from ultrafine waste tailings by oil agglomerate flotation [J]. Minerals Engineering, 2012, 39: 133–139. DOI: https://doi.org/10.1016/j.mineng.2012.07.006.

EBRAHIMI H, KARAMOOZIAN M, SAGHRAVANI S F. Interaction of applying stable micro-nano bubbles and ultrasonic irradiation in coal flotation [J]. International Journal of Coal Preparation and Utilization, 2020: 1–15. DOI: https://doi.org/10.1080/19392699.2020.1732947.

PENG F F, YU X. Pico-nano bubble column flotation using static mixer-venturi tube for Pittsburgh No. 8 coal seam [J]. International Journal of Mining Science and Technology, 2015, 25(3): 347–354. DOI: https://doi.org/10.1016/jijmst.2015.03.004.

RALSTON J, FORNASIERO D, HAYES R. Bubble-particle attachment and detachment in flotation [J]. International Journal of Mineral Processing, 1999, 56(1–4): 133–164. DOI: https://doi.org/10.1016/S0301-7516(98)00046-5.

AZEVEDO A, ETCHEPARE R, CALGAROTO S, et al. Aqueous dispersions of nanobubbles: Generation, properties and features [J]. Minerals Engineering, 2016, 94: 29–37. DOI: https://doi.org/10.1016/j.mineng.2016.05.001.

ETCHEPARE R, OLIVEIRA H, NICKNIG M, et al. Nanobubbles: Generation using a multiphase pump, properties and features in flotation [J]. Minerals Engineering, 2017, 112: 19–26. DOI: https://doi.org/10.1016/j.mineng.2017.06.020.

OLIVEIRA H, AZEVEDO A, RUBIO J. Nanobubbles generation in a high-rate hydrodynamic cavitation tube [J]. Minerals Engineering, 2018, 116: 32–34. DOI: https://doi.org/10.1016/j.mineng.2017.10.020.

AGARWAL A, NG W J, LIU Yu. Principle and applications of microbubble and nanobubble technology for water treatment [J]. Chemosphere, 2011, 84(9): 1175–1180. DOI: https://doi.org/10.1016/j.chemosphere.2011.05.054.

LI Heng-zhen, HU Li-ming, SONG De-jun, et al. Characteristics of micro-nano bubbles and potential application in groundwater bioremediation [J]. Water Environment Research, 2014, 86(9): 844–851. DOI: https://doi.org/10.2175/106143014X14062131177953.

TASAKI T, WADA T, BABA Y, et al. Degradation of surfactants by an integrated nanobubbles/VUV irradiation technique [J]. Industrial & Engineering Chemistry Research, 2009, 48(9): 4237–4244. DOI: https://doi.org/10.1021/ie801279b.

CALGAROTO S, AZEVEDO A, RUBIO J. Separation of amine-insoluble species by flotation with nano and microbubbles [J]. Minerals Engineering, 2016, 89: 24–29. DOI: https://doi.org/10.1016/j.mineng.2016.01.006.

FAN Mao-ming, TAO D, HONAKER R, et al. Nanobubble generation and its application in froth flotation (part I): Nanobubble generation and its effects on properties of microbubble and millimeter scale bubble solutions [J]. Mining Science and Technology (China), 2010, 20(1): 1–19. DOI: https://doi.org/10.1016/S1674-5264(09)60154-X.

FAN Mao-ming, TAO D, HONAKER R, et al. Nanobubble generation and its applications in froth flotation (part II): Fundamental study and theoretical analysis [J]. Mining Science and Technology (China), 2010, 20(2): 159–177. DOI: https://doi.org/10.1016/S1674-5264(09)60179-4.

CALGAROTO S, AZEVEDO A, RUBIO J. Flotation of quartz particles assisted by nanobubbles [J]. International Journal of Mineral Processing, 2015, 137: 64–70. DOI: https://doi.org/10.1016/j.minpro.2015.02.010.

THEODORAKIS P E, CHE Zhi-zhao. Surface nanobubbles: Theory, simulation, and experiment: A review [J]. Advances in Colloid and Interface Science, 2019, 272: 101995. DOI: https://doi.org/10.1016/j.cis.2019.101995.

VAZIRI H B, JIN J, DANG L X, et al. Attachment, coalescence, and spreading of carbon dioxide nanobubbles at pyrite surfaces [J]. Langmuir, 2018, 34(47): 14317–14327. DOI: https://doi.org/10.1021/acs.langmuir.8b02929.

VAZIRI H B, MILLER J D. The effect of carbon dioxide and nitrogen on pyrite surface properties and flotation response [J]. Minerals Engineering, 2019, 144: 106048. DOI: https://doi.org/10.1016/j.mineng.2019.106048.

FAN Mao-ming, TAO D, HONAKER R, et al. Nanobubble generation and its applications in froth flotation (part III): Specially designed laboratory scale column flotation of phosphate [J]. Mining Science and Technology (China), 2010, 20(3): 317–338. DOI: https://doi.org/10.1016/S1674-5264(09)60205-2.

NAKHAEI F, POURKARIMI Z. Desulphurisation of iron ore slime by column flotation with nano-micro bubbles [C]//XXX International Mineral Processing Congress (IMPC 2020). Cape Town, South Africa, 2020. https://www.impc2020.com/component/phocadownload/file/8-impc-2020-abstract-book.

FAN Mao-ming, TAO D, HONAKER R, et al. Nanobubble generation and its applications in froth flotation (part IV): Mechanical cells and specially designed column flotation of coal [J]. Mining Science and Technology (China), 2010, 20(5): 641–671. DOI: https://doi.org/10.1016/S1674-5264(09)60259-3.

SOBHY A, TAO D. Nanobubble column flotation of fine coal particles and associated fundamentals [J]. International Journal of Mineral Processing, 2013, 124: 109–116. DOI: https://doi.org/10.1016/j.minpro.2013.04.016.

AHMADI R, KHODADADI D A, ABDOLLAHY M, et al. Nano-microbubble flotation of fine and ultrafine chalcopyrite particles [J]. International Journal of Mining Science and Technology, 2014, 24(4): 559–566. DOI: https://doi.org/10.1016/j.ijmst.2014.05.021.

POURKARIMI Z, REZAI B, NOAPARAST M. Effective parameters on generation of nanobubbles by cavitation method for froth flotation applications [J]. Physicochemical Problems of Mineral Processing, 2017, 53(2): 920–942. DOI: https://doi.org/10.5277/ppmp170220.

TAO Dong-ping, FAN Mao-ming, WU Zhong-xia, et al. Investigation of effects of nanobubbles on phosphate ore flotation [J]. International Journal of Georesources and Environment, 2018, 4(3): 133–140. DOI: https://doi.org/10.15273/ijge.2018.03.022.

FAN Mao-ming, TAO D. A study on picobubble enhanced coarse phosphate froth flotation [J]. Separation Science and Technology, 2008, 43(1): 1–10. DOI: https://doi.org/10.1080/01496390701747853.

CHANG Guo-hui, XING Yao-wen, ZHANG Fan-fan, et al. Effect of nanobubbles on the flotation performance of oxidized coal [J]. ACS Omega, 2020, 5(32): 20283–20290. DOI: https://doi.org/10.1021/acsomega.0c02154.

POURKARIMA Z, REZAI B, NOAPARAST M. Nanobubbles effect on the mechanical flotation of phosphate ore fine particles [J]. Int J Physicochemical Problems of Mineral Processing, 2018, 54(2): 278–292. DOI: https://doi.org/10.5277/ppmp1804.

GUI Xia-hui, LIU Jiong-tian, CAO Yi-jun, et al. Process intensification of fine coal separation using two-stage flotation column [J]. Journal of Central South University, 2013, 20(12): 3648–3659. DOI: https://doi.org/10.1007/s11771-013-1892-1.

NAKHAEI F, IRANNAJAD M, MOHAMMADNEJAD S, et al. The effect of column flotation operational variables on desulfurization of iron ore concentrate [J]. Journal of Analytical and Numerical Methods in Mining Engineering, 2020, 9(21): 43–58. DOI: https://doi.org/10.29252/anm.2019.9114.1315.

NAKHAEI F, IRANNAJAD M, MOHAMMADNEJAD S. Evaluation of column flotation froth behavior by image analysis: Effects of operational factors in desulfurization of iron ore concentrate [J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2018, 40(19): 2286–2306. DOI: https://doi.org/10.1080/15567036.2018.1486485.

IRANNAJAD M, NAKHAEI F, MOHAMMADNEJAD S. Correlation between column flotation froth image features in respect to operational variables [J]. Journal of Mineral Resources Engineering, 2018, 3(1): 59–76. DOI: https://doi.org/10.30479/jmre.2018.1391.

SOLTANPOUR R, IRANNAJAD M, NAKHAEI F. Investigation of effective operating parameters on carrying capacity in column flotation of copper sulfide minerals [J]. Particulate Science and Technology, 2019, 37(6): 677–684. DOI: https://doi.org/10.1080/02726351.2018.1435593.

LIU Hong-jun, ZHANG Wei, SUN Chun-bao. Influence of bubble diameter and solids concentration on bubble stability: Development of a novel analytical approach [J]. Journal of Central South University, 2014, 21(9): 3588–3595. DOI: https://doi.org/10.1007/s11771-014-2340-6.

HAMPTON M A, NGUYEN A V. Nanobubbles and the nanobubble bridging capillary force [J]. Advances in Colloid and Interface Science, 2010, 154(1, 2): 30–55. DOI: https://doi.org/10.1016/j.cis.2010.01.006.

POURKARIMI Z, REZAI B, NOAPARAST M, et al. Proving the existence of nanobubbles produced by hydrodynamic cavitation and their significant effects in powder flotation [J]. Advanced Powder Technology, 2021, 32(5): 1810–1818. DOI: https://doi.org/10.1016/j.apt.2021.03.039.

MA Fang-yuan, TAO Dong-ping, TAO You-jun. Effects of nanobubbles in column flotation of Chinese sub-bituminous coal [J]. International Journal of Coal Preparation and Utilization, 2019: 1–17. DOI: https://doi.org/10.1080/19392699.2019.1692340.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

Project supported by Iran Mineral Processing Research Center (IMPRC)

Contributors

Fatemeh Taghavi, Fardis Nakhaei and Ziaeddin Pourkarimi provided experimental data, analyzed the measured data, and edited the original draft of manuscript. Mohammad Noaparast supervised the whole experiment.

Conflict of interest

All authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Taghavi, F., Noaparast, M., Pourkarimi, Z. et al. Comparison of mechanical and column flotation performances on recovery of phosphate slimes in presence of nano-microbubbles. J. Cent. South Univ. 29, 102–115 (2022). https://doi.org/10.1007/s11771-022-4925-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-4925-9