Abstract

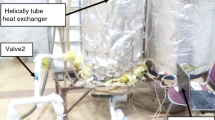

In present work, a helical double tube heat exchanger is proposed in which an advanced turbulator with blades, semi-conical part, and two holes is inserted in inner section. Two geometrical parameters, including angle of tabulator’s blades (θ) and number of tabulator’s blades (N), are considered. Results indicated that firstly, the best thermal stratification is achieved at θ=180°. Furthermore, at the lowest studied mass flow rate (\(\dot m = 8 \times {10^{ - 3}}\,{\rm{kg}}/{\rm{s}}\)), heat transfer coefficient of turbulator with blade angle of 180° is 130.77%, 25%, and 36.36% higher than cases including without turbulator, with turbulator with blade angle of θ=240°, and θ =360°, respectively. Moreover, case with N=12 showed the highest overall performance. At the highest studied mass flow rate (\(\dot m = 5.842 \times {10^{ - 2}}{\rm{kg}}/{\rm{s}}\)), heat transfer coefficient for case with N=12 is up to 54.76%, 27.45%, and 6.56% higher than cases including without turbulator, with turbulator with N=6, and with turbulator with N=9, respectively.

摘要

本文提出了一种内部具有叶片及半圆锥形双孔紊流器的螺旋双管换热器。研究了紊流叶片角θ和紊流叶片数N 对传热性能的影响。结果表明: 热分层在θ=180°时达到最佳; 在最小质量流率(ṁ=8×10−3 kg/s)条件下, 叶片倾角为180°的紊流器的换热系数比不含紊流器、及叶片倾角为240°和360°的紊 流器分别高130.77%、25% 和36.36%。N=12 的综合性能表现最好。在最大质量流率下(ṁ=5.842×10−2 kg/s), N=12 时的换热系数比无紊流器、叶片数为6 和9 时的换热系数分别提高了54.76%、27.45% 和6.56%。

Similar content being viewed by others

Abbreviations

- c p :

-

Specific heat capacity, kJ/(kg·K)

- D i :

-

Diameter of cold channel, m

- d i :

-

Diameter of hot channel, m

- f :

-

Darcy friction factor

- g :

-

Gravitational acceleration, m/s2

- h :

-

Heat transfer coefficient, W/(m2·K)

- h t :

-

Height of the tabulator’s blades, m

- k :

-

Thermal conductivity, W/(m·K)

- N :

-

Blade number of the tabulator

- P :

-

Pressure, Pa

- R :

-

Radius of the heat exchanger round, m

- R C :

-

Radius of the coil, m

- R i :

-

Inner radius of the proposed Turbulator, m

- R o :

-

Outer radius of the proposed Turbulator, m

- r :

-

Radius of the channel of the Turbulator, m

- r i :

-

Radius of the Turbulator’s holes, m

- S :

-

Source term, kJ/m3

- T :

-

Temperature, °C

- t :

-

Time, s

- u :

-

Fluid velocity, m/s

- w :

-

Thickness of the turbulator’s blades, m

- Pr :

-

Prandtl number [Pr=(cp·μ)/k]

- Pe :

-

Péclet number [Pe = Re·Pr]

- Re :

-

Reynolds number [Re=(ρ·u·d)/μ]

- Nu :

-

Nusselt number [Nu=(h·d)/k]

- ρ :

-

Density, kg/m3

- μ :

-

Viscosity, Pa·s

- θ :

-

Angle of the tabulator’s blades, (°)

- η :

-

Overall performance

- 0:

-

Reference

- m:

-

Average

- h:

-

Hydraulic

- t:

-

Turbulator

References

LIU S, SAKR M. A comprehensive review on passive heat transfer enhancements in pipe exchangers [J]. Renewable and Sustainable Energy Reviews, 2013, 19: 64–81. DOI: https://doi.org/10.1016/j.rser.2012.11.021.

ROHSENOW W M, HARTNETT J P, CHO Y I. Handbook of heat transfer. Vol. 3 [M]. New York: McGraw-Hill, 1998. ISBN 0-07-053555-8

NOORBAKHSH M, ZABOLI M, MOUSAVI AJAROSTAGHI S S. Numerical evaluation of the effect of using twisted tapes as turbulator with various geometries in both sides of a double-pipe heat exchanger [J]. Journal of Thermal Analysis and Calorimetry, 2020, 140(3): 1341–1353. DOI: https://doi.org/10.1007/s10973-019-08509-w.

OLFIAN H, ZABIHI SHESHPOLI A, MOUSAVI AJAROSTAGHI S S. Numerical evaluation of the thermal performance of a solar air heater equipped with two different types of baffles [J]. Heat Transfer, 2020, 49(3): 1149–1169. DOI: https://doi.org/10.1002/htj.21656.

OUTOKESH M, AJAROSTAGHI S S M, BOZORGZADEH A, SEDIGHI K. Numerical evaluation of the effect of utilizing twisted tape with curved profile as a turbulator on heat transfer enhancement in a pipe [J]. Journal of Thermal Analysis and Calorimetry, 2020, 140(3): 1537–1553. DOI: https://doi.org/10.1007/s10973-020-09336-0.

HASHEMI KAROUEI S H, AJAROSTAGHI S S M, GORJI-BANDPY M, HOSSEINI FARD S R. Laminar heat transfer and fluid flow of two various hybrid nanofluids in a helical double-pipe heat exchanger equipped with an innovative curved conical turbulator [J]. Journal of Thermal Analysis and Calorimetry, 2021, 143(2): 1455–1466. DOI: https://doi.org/10.1007/s10973-020-09425-0.

MOUSAVI AJAROSTAGHI S S, SHIRZAD M, RASHIDI S, LI L K B. Heat transfer performance of a nanofluid-filled tube with wall corrugations and center-cleared twisted-tape inserts [J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2020: 1841860. DOI: https://doi.org/10.1080/15567036.2020.1841860.

RASHIDI S, ZADE N M, ESFAHANI J A. Thermo-fluid performance and entropy generation analysis for a new eccentric helical screw tape insert in a 3D tube [J]. Chemical Engineering and Processing: Process Intensification, 2017, 117: 27–37. DOI: https://doi.org/10.1016/j.cep.2017.03.013.

MOGHADDASZADEH N, RASHIDI S, ABOLFAZLI ESFAHANI J. Potential of gear-ring turbulator in three-dimensional heat exchanger tube from second law of thermodynamic viewpoint [J]. International Journal of Numerical Methods for Heat & Fluid Flow, 2019, 29(4): 1526–1543. DOI: https://doi.org/10.1108/hff-05-2018-0250.

MOGHADAS ZADE N, AKAR S, RASHIDI S, ABOLFAZLI ESFAHANI J. Thermo-hydraulic analysis for a novel eccentric helical screw tape insert in a three dimensional tube [J]. Applied Thermal Engineering, 2017, 124: 413–421. DOI: https://doi.org/10.1016/j.applthermaleng.2017.06.036.

NI Ming-long, CHEN Ya-ping, DONG Cong, WU Jia-feng. Numerical simulation of heat transfer and flow of cooling air in triangular wavy fin channels [J]. Journal of Central South University, 2014, 21(7): 2759–2765. DOI: https://doi.org/10.1007/s11771-014-2238-3.

WANG Wei-han, CHENG Dao-lai, LIU Tao, LIU Ying-hao. Performance comparison for oil-water heat transfer of circumferential overlap trisection helical baffle heat exchanger [J]. Journal of Central South University, 2016, 23(10): 2720–2727. DOI: https://doi.org/10.1007/s11771-016-3333-4.

NEMATI H, RAHIMZADEH A R, WANG Chi-chuan. Heat transfer simulation of annular elliptical fin-and-tube heat exchanger by transition SST model [J]. Journal of Central South University, 2020, 27(8): 2324–2337. DOI: https://doi.org/10.1007/s11771-020-4452-5.

KITAGAWA A, KOSUGE K, UCHIDA K, HAGIWARA Y. Heat transfer enhancement for laminar natural convection along a vertical plate due to sub-millimeter-bubble injection [J]. Experiments in Fluids, 2008, 45(3): 473–484. DOI: https://doi.org/10.1007/s00348-008-0490-8.

CELATA G P, CHIARADIA A, CUMO M, D’ANNIBALE F. Heat transfer enhancement by air injection in upward heated mixed-convection flow of water [J]. International Journal of Multiphase Flow, 1999, 25(6, 7): 1033–1052. DOI: https://doi.org/10.1016/S0301-9322(99)00059-2.

WANG Zhi-qi, HE Ni, XIA Xiao-xia, LIU Li-wen. Experimental investigation on boiling heat transfer and pressure drop of R245fa in a horizontal micro-fin tube [J]. Journal of Central South University, 2019, 26(11): 3200–3212. DOI: https://doi.org/10.1007/s11771-019-4246-9.

CHANG F, DHIR V K. Mechanisms of heat transfer enhancement and slow decay of swirl in tubes using tangential injection [J]. International Journal of Heat and Fluid Flow, 1995, 16(2): 78–87. DOI: https://doi.org/10.1016/0142-727X(94)00016-6.

XU Peng, YU Bo-ming, QIU Shu-xia, POH H J, MUJUMDAR A S. Turbulent impinging jet heat transfer enhancement due to intermittent pulsation [J]. International Journal of Thermal Sciences, 2010, 49(7): 1247–1252. DOI: https://doi.org/10.1016/j.ijthermalsci.2010.01.020.

DEHGHAN M, JAMAL-ABAD M T, RASHIDI S. Analytical interpretation of the local thermal non-equilibrium condition of porous media imbedded in tube heat exchangers [J]. Energy Conversion and Management, 2014, 85: 264–271. DOI: https://doi.org/10.1016/j.enconman.2014.05.074.

RASHIDI S, DEHGHAN M, ELLAHI R, RIAZ M, JAMAL-ABAD M T. Study of stream wise transverse magnetic fluid flow with heat transfer around an obstacle embedded in a porous medium [J]. Journal of Magnetism and Magnetic Materials, 2015, 378: 128–137. DOI: https://doi.org/10.1016/j.jmmm.2014.11.020.

RASHIDI S, KASHEFI M H, KIM K C, SAMIMI-ABIANEH O. Potentials of porous materials for energy management in heat exchangers–A comprehensive review [J]. Applied Energy, 2019, 243: 206–232. DOI: https://doi.org/10.1016/j.apenergy.2019.03.200.

SHAMSABADI H, RASHIDI S, ESFAHANI J A. Entropy generation analysis for nanofluid flow inside a duct equipped with porous baffles [J]. Journal of Thermal Analysis and Calorimetry, 2019, 135(2): 1009–1019. DOI: https://doi.org/10.1007/s10973-018-7350-4.

ALIZADEH R, GOMARI S R, ALIZADEH A, KARIMI N, LI L K B. Combined heat and mass transfer and thermodynamic irreversibilities in the stagnation-point flow of Casson rheological fluid over a cylinder with catalytic reactions and inside a porous medium under local thermal nonequilibrium [J]. Computers & Mathematics with Applications, 2021, 81: 786–810. DOI: https://doi.org/10.1016/j.camwa.2019.10.021.

ELLIOTT A, TORABI M, KARIMI N, CUNNINGHAM S. On the effects of internal heat sources upon forced convection in porous channels with asymmetric thick walls [J]. International Communications in Heat and Mass Transfer, 2016, 73: 100–110. DOI: https://doi.org/10.1016/j.icheatmasstransfer.2016.02.016.

SIAVASHI M, MIRI JOIBARY S M. Numerical performance analysis of a counter-flow double-pipe heat exchanger with using nanofluid and both sides partly filled with porous media [J]. Journal of Thermal Analysis and Calorimetry, 2019, 135(2): 1595–1610. DOI: https://doi.org/10.1007/s10973-018-7829-z.

POURRAHMANI H, MOGHIMI M, SIAVASHI M, SHIRBANI M. Sensitivity analysis and performance evaluation of the PEMFC using wave-like porous ribs [J]. Applied Thermal Engineering, 2019, 150: 433–444. DOI: https://doi.org/10.1016/j.applthermaleng.2019.01.010.

SIAVASHI M, TALESH BAHRAMI H R, AMINIAN E, SAFFARI H. Numerical analysis on forced convection enhancement in an annulus using porous ribs and nanoparticle addition to base fluid [J]. Journal of Central South University, 2019, 26(5): 1089–1098. DOI: https://doi.org/10.1007/s11771-019-4073-z.

VALIZADEH ARDALAN M, ALIZADEH R, FATTAHI A, ADELIAN RASI N, DORANEHGARD M H, KARIMI N. Analysis of unsteady mixed convection of Cu-water nanofluid in an oscillatory, lid-driven enclosure using lattice Boltzmann method [J]. Journal of Thermal Analysis and Calorimetry, 2021, 145(4): 2045–2061. DOI: https://doi.org/10.1007/s10973-020-09789-3.

MAJID S, MOHAMMAD J. Optimal selection of annulus radius ratio to enhance heat transfer with minimum entropy generation in developing laminar forced convection of water-Al2O3 nanofluid flow [J]. Journal of Central South University, 2017, 24(8): 1850–1865. DOI: https://doi.org/10.1007/s11771-017-3593-7.

ZABOLI M, AJAROSTAGHI S S M, NOORBAKHSH M, DELAVAR M A. Effects of geometrical and operational parameters on heat transfer and fluid flow of three various water based nanofluids in a shell and coil tube heat exchanger [J]. SN Applied Sciences, 2019, 1(11): 1–17. DOI: https://doi.org/10.1007/s42452-019-1431-2.

AJAROSTAGHI S S M, ZABOLI M, NOURBAKHSH M. Numerical evaluation of turbulence heat transfer and fluid flow of hybrid nanofluids in a pipe with innovative vortex generator [J]. Journal of Thermal Analysis and Calorimetry, 2021, 143(2): 1583–1597. DOI: https://doi.org/10.1007/s10973-020-10205-z.

SHIRZAD M, AJAROSTAGHI S S M, DELAVAR M A, SEDIGHI K. Improve the thermal performance of the pillow plate heat exchanger by using nanofluid: Numerical simulation [J]. Advanced Powder Technology, 2019, 30(7): 1356–1365. DOI: https://doi.org/10.1016/j.apt.2019.04.011.

HAMEDANI F A, AJAROSTAGHI S S M, HOSSEINI S A. Numerical evaluation of the effect of geometrical and operational parameters on thermal performance of nanofluid flow in convergent-divergent tube [J]. Journal of Thermal Analysis and Calorimetry, 2020, 140(3): 1483–1505. DOI: https://doi.org/10.1007/s10973-019-08765-w.

KAZEMI MOGHADAM H, MOUSAVI AJAROSTAGHI S S, PONCET S. Extensive numerical analysis of the thermal performance of a corrugated tube with coiled wire [J]. Journal of Thermal Analysis and Calorimetry, 2020, 140(3): 1469–1481. DOI: https://doi.org/10.1007/s10973-019-08876-4.

NOORBAKHSH M, POURFALLAH M, AJAROSTAGHI S S M, ZABOLI M. Numerical evaluation and the effects of geometrical and operational parameters on thermal performance of the shell and double coil tube heat exchanger [J]. Heat Transfer, 2020, 49(8): 4678–4703. DOI: https://doi.org/10.1002/htj.21847.

AFSHARPANAH F, MOUSAVI AJAROSTAGHI S S, SEDIGHI K. The influence of geometrical parameters on the ice formation enhancement in a shell and double coil ice storage system [J]. SN Applied Sciences, 2019, 1(10): 1–14. DOI: https://doi.org/10.1007/s42452-019-1317-3.

PAKZAD K, MOUSAVI AJAROSTAGHI S S, SEDIGHI K. Numerical simulation of solidification process in an ice-on-coil ice storage system with serpentine tubes [J]. SN Applied Sciences, 2019, 1(10): 1–12. DOI: https://doi.org/10.1007/s42452-019-1316-4.

JAVADI H, AJAROSTAGHI S S M, MOUSAVI S S, POURFALLAH M. Thermal analysis of a triple helix ground heat exchanger using numerical simulation and multiple linear regression [J]. Geothermics, 2019, 81: 53–73. DOI: https://doi.org/10.1016/j.geothermics.2019.04.005.

JAVADI H, MOUSAVI AJAROSTAGHI S S, POURFALLAH M, ZABOLI M. Performance analysis of helical ground heat exchangers with different configurations [J]. Applied Thermal Engineering, 2019, 154: 24–36. DOI: https://doi.org/10.1016/j.applthermaleng.2019.03.021.

MOUSAVI AJAROSTAGHI S S, PONCET S, SEDIGHI K, AGHAJANI DELAVAR M. Numerical modeling of the melting process in a shell and coil tube ice storage system for air-conditioning application [J]. Applied Sciences, 2019, 9(13): 2726. DOI: https://doi.org/10.3390/app9132726.

MOUSAVI AJAROSTAGHI S S, SEDIGHI K, AGHAJANI DELAVAR M, PONCET S. Numerical study of a horizontal and vertical shell and tube ice storage systems considering three types of tube [J]. Applied Sciences, 2020, 10(3): 1059. DOI: https://doi.org/10.3390/app10031059.

MAHENDRAN J. Experimental analysis of shell and tube heat exchanger using flower baffle plate configuration [J]. Materials Today: Proceedings, 2020, 21: 419–424. DOI: https://doi.org/10.1016/j.matpr.2019.06.380.

AKYÜREK E F, GELIŞ K, ŞAHIN B, MANAY E. Experimental analysis for heat transfer of nanofluid with wire coil turbulators in a concentric tube heat exchanger [J]. Results in Physics, 2018, 9: 376–389. DOI: https://doi.org/10.1016/j.rinp.2018.02.067.

SHINDE S, CHAVAN U. Numerical and experimental analysis on shell side thermo-hydraulic performance of shell and tube heat exchanger with continuous helical FRP baffles [J]. Thermal Science and Engineering Progress, 2018, 5: 158–171. DOI: https://doi.org/10.1016/j.tsep.2017.11.006.

LI Nian-qi, CHEN Jian, CHENG Tao, KLEMES J J, VARBANOV P S, WANG Qiu-wang, YANG Wei-sheng, LIU Xia, ZENG Min. Analysing thermal-hydraulic performance and energy efficiency of shell-and-tube heat exchangers with longitudinal flow based on experiment and numerical simulation [J]. Energy, 2020, 202: 117757. DOI: https://doi.org/10.1016/j.energy.2020.117757.

McCONALOGUE D J, SRLVASTAVA R S. Motion of a fluid in a curved tube [J]. Proceedings of the Royal Society of London Series A Mathematical and Physical Sciences, 1968, 307(1488): 37–53. DOI: https://doi.org/10.1098/rspa.1968.0173.

OLFIAN H, AJAROSTAGHI S S M, FARHADI M, RAMIAR A. Melting and solidification processes of phase change material in evacuated tube solar collector with U-shaped spirally corrugated tube [J]. Applied Thermal Engineering, 2021, 182: 116149. DOI: https://doi.org/10.1016/j.applthermaleng.2020.116149.

WANG Wei, ZHANG Ya-ning, LI Bing-xi, HAN Huai-zhi, GAO Xiao-yan. Influence of geometrical parameters on turbulent flow and heat transfer characteristics in outward helically corrugated tubes [J]. Energy Conversion and Management, 2017, 136: 294–306. DOI: https://doi.org/10.1016/j.enconman.2017.01.029.

STEENBERGEN W, VOSKAMP J. The rate of decay of swirl in turbulent pipe flow [J]. Flow Measurement and Instrumentation, 1998, 9(2): 67–78. DOI: https://doi.org/10.1016/S0955-5986(98)00016-8.

SADIGHI DIZAJI H, JAFARMADAR S, MOBADERSANI F. Experimental studies on heat transfer and pressure drop characteristics for new arrangements of corrugated tubes in a double pipe heat exchanger [J]. International Journal of Thermal Sciences, 2015, 96: 211–220. DOI: https://doi.org/10.1016/j.ijthermalsci.2015.05.009.

ZACHAR A. Analysis of coiled-tube heat exchangers to improve heat transfer rate with spirally corrugated wall [J]. International Journal of Heat and Mass Transfer, 2010, 53(19, 20): 3928–3939. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2010.05.011.

RAINIERI S, BOZZOLI F, CATTANI L, PAGLIARINI G. Compound convective heat transfer enhancement in helically coiled wall corrugated tubes [J]. International Journal of Heat and Mass Transfer, 2013, 59: 353–362. DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2012.12.037.

YARMOHAMMADI S, FARHADI M. Optimization of thermal and flow characteristics of R-404A vapor condensation inside corrugated tubes [J]. Experimental Thermal and Fluid Science, 2016, 79: 1–12. DOI: https://doi.org/10.1016/j.expthermflusci.2016.06.012.

JAFARI M, DABIRI S, FARHADI M, SEDIGHI K. Effects of a three-lobe swirl generator on the thermal and flow fields in a heat exchanging tube: An experimental and numerical approach [J]. Energy Conversion and Management, 2017, 148: 1358–1371. DOI: https://doi.org/10.1016/j.enconman.2017.06.074.

BEJAN A. Convection heat transfer [M]. Hoboken, NJ, USA: John Wiley & Sons, Inc., 2013. DOI: https://doi.org/10.1002/9781118671627.

BARAGH S, SHOKOUHMAND H, AJAROSTAGHI S S M, NIKIAN M. An experimental investigation on forced convection heat transfer of single-phase flow in a channel with different arrangements of porous media [J]. International Journal of Thermal Sciences, 2018, 134: 370–379. DOI: https://doi.org/10.1016/j.ijthermalsci.2018.04.030.

BARAGH S, SHOKOUHMAND H, AJAROSTAGHI S S M. Experiments on mist flow and heat transfer in a tube fitted with porous media [J]. International Journal of Thermal Sciences, 2019, 137: 388–398. DOI: https://doi.org/10.1016/j.ijthermalsci.2018.11.030.

HASHEMI KAROUEI S H, MOUSAVI AJAROSTAGHI S S. Influence of a curved conical turbulator on heat transfer augmentation in a helical double-pipe heat exchanger [J]. Heat Transfer, 2021, 50(2): 1872–1894. DOI: https://doi.org/10.1002/htj.21960.

NOORBAKHSH M, AJAROSTAGHI S S M, ZABOLI M, KIANI B. Thermal analysis of nanofluids flow in a double pipe heat exchanger with twisted tapes insert in both sides [J]. Journal of Thermal Analysis and Calorimetry, 2021: 1–12. DOI: https://doi.org/10.1007/s10973-021-10738-x.

SAFFARIAN M R, MORAVEJ M, DORANEHGARD M H. Heat transfer enhancement in a flat plate solar collector with different flow path shapes using nanofluid [J]. Renewable Energy, 2020, 146: 2316–2329. DOI: https://doi.org/10.1016/j.renene.2019.08.081.

BOZORG M V, HOSSEIN DORANEHGARD M, HONG Kun, XIONG Qin-gang. CFD study of heat transfer and fluid flow in a parabolic trough solar receiver with internal annular porous structure and synthetic oil-Al2O3 nanofluid [J]. Renewable Energy, 2020, 145: 2598–2614. DOI: https://doi.org/10.1016/j.renene.2019.08.042.

SIAVASHI M, KARIMI K, XIONG Qin-gang, DORANEHGARD M H. Numerical analysis of mixed convection of two-phase non-Newtonian nanofluid flow inside a partially porous square enclosure with a rotating cylinder [J]. Journal of Thermal Analysis and Calorimetry, 2019, 137(1): 267–287. DOI: https://doi.org/10.1007/s10973-018-7945-9.

ALIZADEH R, ABAD J M N, FATTAHI A, MOHEBBI M R, DORANEHGARD M H, LI L K B, ALHAJRI E, KARIMI N. A machine learning approach to predicting the heat convection and thermodynamics of an external flow of hybrid nanofluid [J]. Journal of Energy Resources Technology, 2021, 143(7): 070908. DOI: https://doi.org/10.1115/1.4049454.

SAEDODIN S, ZABOLI M, MOUSAVI AJAROSTAGHI S S. Hydrothermal analysis of heat transfer and thermal performance characteristics in a parabolic trough solar collector with Turbulence-Inducing elements [J]. Sustainable Energy Technologies and Assessments, 2021, 46: 101266. DOI: https://doi.org/10.1016/j.seta.2021.101266.

ABBASPOUR M, MOUSAVI AJAROSTAGHI S S, HEJAZI RAD S A H, NIMAFAR M. Heat transfer improvement in a tube by inserting perforated conical ring and wire coil as turbulators [J]. Heat Transfer, 2021, 50(6): 6164–6188. DOI: https://doi.org/10.1002/htj.22167.

ZABOLI M, SAEDODIN S, MOUSAVI AJAROSTAGHI S S, NOURBAKHSH M. Numerical evaluation of the heat transfer in a shell and corrugated coil tube heat exchanger with three various water-based nanofluids [J]. Heat Transfer, 2021, 50(6): 6043–6067. DOI: https://doi.org/10.1002/htj.22161.

SCHMIDT E F. Heat transfer and pressure loss in spiral tubes [J]. Chemie Ingenieur Technik, 1967, 39(13): 781–789. DOI: https://doi.org/10.1002/cite.330391302.

HIROMASA I. Friction factors for turbulent flow in curved pipes [J]. Transactions of American Society of Mechanical Engineers, Journal of Basic Engineering, 1959, 81: 123–132. https://doi.org/10.1115/1.4008390.

LIM K Y, HUNG Y M, TAN B T. Performance evaluation of twisted-tape insert induced swirl flow in a laminar thermally developing heat exchanger [J]. Applied Thermal Engineering, 2017, 121: 652–661. DOI: https://doi.org/10.1016/j.applthermaleng.2017.04.134.

ZHENG Nian-ben, LIU Peng, SHAN Feng, LIU Jia-ju, LIU Zhi-chun, LIU Wei. Numerical studies on thermo-hydraulic characteristics of laminar flow in a heat exchanger tube fitted with vortex rods [J]. International Journal of Thermal Sciences, 2016, 100: 448–456. DOI: https://doi.org/10.1016/j.ijthermalsci.2015.09.008.

GUO Jian, FAN Ai-wu, ZHANG Xiao-yu, LIU Wei. A numerical study on heat transfer and friction factor characteristics of laminar flow in a circular tube fitted with center-cleared twisted tape [J]. International Journal of Thermal Sciences, 2011, 50(7): 1263–1270. DOI: https://doi.org/10.1016/j.ijthermalsci.2011.02.010.

SAINI R, KARIMI N, DUAN Lian, SADIKI A, MEHDIZADEH A. Effects of near wall modeling in the improved-delayed-detached-eddy-simulation (IDDES) methodology [J]. Entropy, 2018, 20(10): 771. DOI: https://doi.org/10.3390/e20100771.

AKIYAMA M, CHENG K C. Laminar forced convection heat transfer in curved pipes with uniform wall temperature [J]. International Journal of Heat and Mass Transfer, 1972, 15(7): 1426–1431. DOI: https://doi.org/10.1016/0017-9310(72)90023-3.

Author information

Authors and Affiliations

Contributions

The overarching research goals were developed by Seyed Hossein HASHEMI KAROUEI and Seyed Soheil MOUSAVI AJAROSTAGHI. Also, they performed the numerical simulations and analyzed the obtained results. The initial draft of the manuscript was written by Seyed Hossein HASHEMI KAROUEI, Seyed Soheil MOUSAVI AJAROSTAGHI, and Saman RASHIDI. The initial draft of the manuscript was edited by Elham HOSSEINIRAD. All authors replied to reviewers’ comments and revised the final version.

Corresponding author

Additional information

Conflict of interest

Seyed Hossein HASHEMI KAROUEI, Seyed Soheil MOUSAVI AJAROSTAGHI, Saman RASHIDI, and Elham HOSSEINIRAD declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Hashemi Karouei, S.H., Mousavi Ajarostaghi, S.S., Rashidi, S. et al. An advanced turbulator with blades and semi-conical section for heat transfer improvement in a helical double tube heat exchanger. J. Cent. South Univ. 28, 3491–3506 (2021). https://doi.org/10.1007/s11771-021-4870-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4870-z