Abstract

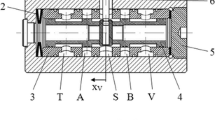

The high-pressure electro-pneumatic servo valve (HESV) is a core element of the high-pressure pneumatic servo system. The annular clearance and the rounded corner of the spool-sleeve can cause the leakage at null position, thereby affecting high-precision control and stability of the servo system. This paper investigates the effects of the clearance structure on leakage behavior at null position of the HESV. A numerical approach was employed to evaluate the effects, and then a mathematical model was established to obtain the variation law of leakage flow rate at null position. The results indicate that the leakage flow rate at null position varies linearly with supply pressure and rounded corner radius, and is nonlinear as a quadratic concave function with annular clearance. The leakage flow rate of the annular clearance and the rounded corner varies with the valve opening in an invariable-nonlinear-linear trend. A test rig system of leakage behavior at null position of the HESV was built to confirm the validity of the numerical model, which agrees well with the conducted experimental study.

摘要

高压电-气伺服阀是高压气动伺服系统的核心部件, 其阀芯阀套结构存在的环形间隙和圆角等问 题, 导致了伺服阀在零位时产生泄漏, 从而影响伺服系统的高精度控制和稳定性. 为了研究高压电气 伺服阀间隙结构对零位泄露特性的影响, 首先, 建立了伺服阀内部跨尺度流场计算模型, 并采用计算-流体力学的方法, 分析了高压电-气伺服阀间隙结构对零位泄漏特性的影响; 然后, 建立了高压气体零 位泄漏流量的数学模型, 得到了带有环形间隙和阀芯圆角的高压电-气伺服阀流量随阀口开度变化的规 律. 结果表明, 滑阀伺服阀零位泄漏量与气体压力和圆角半径变化近似呈线性关系, 与环形间隙高度 呈二次凹函数曲线关系; 带有环形间隙和圆角的高压电-气伺服阀流量随着阀口开度变化的趋势是恒定 −非线性−线性. 最后, 搭建了伺服阀零位泄漏流量特性测试系统, 并通过实验验证了数值计算方法的 准确性.

Similar content being viewed by others

References

XU Zhi-peng, WANG Xuan-yin. Pneumatic resistance network analysis and dimension optimization of high pressure electronic pneumatic pressure reducing valve [J]. Journal of Central South University, 2011, 18(3): 666–671. DOI: https://doi.org/10.1007/s11771-011-0745-z.

ZHOU Miao-lei, TIAN Yan-tao, GAO Wei, YANG Zhi-gang. High precise control method for a new type of piezoelectric electro-hydraulic servo valve [J]. Journal of Central South University of Technology, 2007, 14(6): 832–837. DOI: https://doi.org/10.1007/s11771-007-0158-1.

XU Jun-bo. Design and research of high-speed high-pressure pneumatic on-off valve [D]. Hangzhou: Zhejiang University, 2016. (in Chinese)

LUO Yu-xi, ZHANG Yan-jun, GAO Yu-bao, WANG Xuan-yin, XU Zhi-peng. Simulation and experimental study of high pressure switching expansion reduction considering real gas effect [J]. Journal of Central South University, 2014, 21(6): 2253–2261. DOI: https://doi.org/10.1007/s11771-014-2176-0.

XU Zhi-peng. Research on structure optimization and characteristics of a high pressure pneumatic proportional pressure reducing valve [D]. Hangzhou: Zhejiang University, 2010. (in Chinese)

YIN Yao-bao, ZHANG Li, LI Ling, SHEN Li, FU Jun-yong. Study on pressure and velocity fields of pneumatic high-pressure reduction valve for hydrogen vehicles [J]. Chinese Journal of Construction Machinery, 2011, 9(1): 1–6. DOI: https://doi.org/10.15999/j.cnki.311926.2011.01.011. (in Chinese)

NIE Song-lin, LIU Xiang-yang, YIN Fang-long, JI Hui, ZHANG Jing-xiu. Development of a high-pressure pneumatic on/off valve with high transient performances direct-driven by voice coil motor [J]. Applied Sciences, 2018, 8(4): 611. DOI: https://doi.org/10.3390/app8040611.

SHEN De-jun. Null position characteristics of electrohydraulic servo valve [J]. Measurement & Control Technology, 1981(1): 27–35. (in Chinese)

KANNO T, HASEGAWA T, MIYAZAKI T, YAMAMOTO N, HARAGUCHI D, KAWASHIMA K. Development of a poppet-type pneumatic servo valve [J]. Applied Sciences, 2018, 8(11): 2094. DOI: https://doi.org/10.3390/app8112094.

MORISAKI D, KANNO T, MIYAZAKI T, KAWASHIMA K. Development of a pinch-type servo valve embedded in a pneumatic artificial rubber muscle [C]// 2017 IEEE/SICE International Symposium on System Integration (SII). IEEE, 2017: 374–379. DOI: https://doi.org/10.1109/SII.2017.8279241.

MIYAJIMA T, FUJITA T, SAKAKI K, KAWASHIMA K, KAGAWA T. Development of a digital control system for high-performance pneumatic servo valve [J]. Precision Engineering, 2007, 31(2): 156–161. DOI: https://doi.org/10.1016/j.precisioneng.2006.05.003.

MIYAJIMA T, FUJITA T, SAKAKI K, et al. Digital control of high response pneumatic servo valve [C]// Proceedings of the SICE Annual Conference. IEEE, 2005: 787–792.

CHEN Dong-dong, JIN Yao-lan, ZHOU Zhu, QU Li-peng, ZHANG Xian, ZHANG Bing-cheng. Research on axial grinding and zero position characteristic test system of jet pipe servo valve slide valve [J]. Machine Tool & Hydraulics, 2019, 47(22): 54–56, 110. (in Chinese)

YIN Yao-bao, LIANG Jun-zhe, YUAN Jia-yang, GAO Jing. Analysis on the influence factors of pneumatic servo-mechanism’s characteristics [J]. Journal of South China University of Technology: Natural Science Edition, 2019, 47(12): 17–24.

YIN Yao-bao, LI Chang-ming, ARAKI Kenji. Characteristics of the pneumatic servovalve with symmetric uneven underlaps [J]. Journal of Shanghai Jiao Tong University, 2010, 44(4): 500–505. (in Chinese)

LI Bao-ren, GAO Long-long, YANG Gang. Evaluation and compensation of steady gas flow force on the high-pressure electro-pneumatic servo valve direct-driven by voice coil motor [J]. Energy Conversion and Management, 2013, 67: 92–102. DOI: https://doi.org/10.1016/j.enconman.2012.11.004.

LI Bao-ren, GAO Long-long, YANG Gang. Modeling and control of a novel high-pressure pneumatic servo valve direct-driven by voice coil motor [J]. Journal of Dynamic Systems, Measurement, and Control, 2013, 135(1): 014507. DOI: https://doi.org/10.1115/1.4007702.

GAO Long-long, WU Chuan, ZHANG Di-jia, FU Xiao-yun, LI Bao-ren. Research on a high-accuracy and high-pressure pneumatic servo valve with aerostatic bearing for precision control systems [J]. Precision Engineering, 2019, 60: 355–367. DOI: https://doi.org/10.1016/j.precisioneng.2019.09.005.

LIN Zhen-hao, LI Jun-ye, JIN Zhi-jiang, QIAN Jin-yuan. Fluid dynamic analysis of liquefied natural gas flow through a cryogenic ball valve in liquefied natural gas receiving stations [J]. Energy, 2021, 226: 120376. DOI: https://doi.org/10.1016/j.energy.2021.120376.

HUANG Zhen-hua, HUANG Shi-jie. Two-phase flow simulations of fixed 3D oscillating water columns using OpenFOAM: A comparison of two methods for modeling quadratic power takeoff [J]. Ocean Engineering, 2021, 232: 108600. DOI: https://doi.org/10.1016/j.oceaneng.2021.108600.

ZHANG Hong-tu, ZHANG Ou-ya, LI Bo-tao, ZHANG Jian, XU Xiang-yu, WEI Jian-ping. Effect of drill pipe rotation on gas-solid flow characteristics of negative pressure pneumatic conveying using CFD-DEM simulation [J]. Powder Technology, 2021, 387: 48–60. DOI: https://doi.org/10.1016/j.powtec.2021.04.017.

LISOWSKI E, FILO G. CFD analysis of the characteristics of a proportional flow control valve with an innovative opening shape [J]. Energy Conversion and Management, 2016, 123: 15–28. DOI: https://doi.org/10.1016/j.enconman.2016.06.025.

GUAN Xiao-ping, YANG Ning. CFD simulation of bubble column hydrodynamics with a novel drag model based on EMMS approach [J]. Chemical Engineering Science, 2021, 243: 116758. DOI: https://doi.org/10.1016/j.ces.2021.116758.

ZHOU Yu, NING De-zhi, DONGFANG Liang, CAI Shu-qun. Nonlinear hydrodynamic analysis of an offshore oscillating water column wave energy converter [J]. Renewable and Sustainable Energy Reviews, 2021, 145: 111086. DOI: https://doi.org/10.1016/j.rser.2021.111086.

VERSTEEG H K, MALALASEKERA W. An introduction to computational fluid dynamics: The finite volume method [M]. England: Pearson Education Limited, 2007.

PALUMBO A, PAOLUZZI R, BORGHI M, MILANI M. Forces on a hydraulic valve spool [J]. Proceedings of the JFPS International Symposium on Fluid Power, 1996, 1996(3): 543–548. DOI: https://doi.org/10.5739/isfp.1996.543.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

Project(51705164) supported by the National Natural Science Foundation of China

Contributors

The overall research objectives were developed by GAO Long-long, LI Bao-ren and ZHANG Di-jia. ZHANG Di-jia and GAO Long-long completed the simulation and experimental studies and worked with WU Chuan and ZHAO Zhi-xin to analyze the research data. The first draft of the manuscript was written by ZHANG Di-jia and GAO Long-long. All authors responded to the reviewers’ comments and revised the final version.

Conflict of interest

ZHANG Di-jia, GAO Long-long, WU Chuan, ZHAO Zhi-xin and LI Bao-ren declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Zhang, Dj., Gao, Ll., Wu, C. et al. Numerical and experimental investigation of leakage behavior at null position of high-pressure electro-pneumatic servo valve. J. Cent. South Univ. 28, 3117–3126 (2021). https://doi.org/10.1007/s11771-021-4829-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4829-0