Abstract

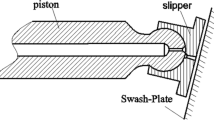

External return mechanism is a mechanical structure applied to axial piston pumps. To study its lubrication characteristics, the Reynolds equation applied to an external return spherical hinge pair was deduced based on the vector equation of relative-motion velocity of the external return spherical hinge pair under the influence of external swash plate inclination and offset distance. The results show that the total friction, axial leakage flow, and maximum value of the maximum oil-film pressure increase with increasing pump-shaft speed and decrease with increasing offset distance in one working cycle when the external-swash-plate inclination is constant. However, the varying offset distance has little effect on the axial leakage flow. The maximum value of the maximum oil-film pressure decreases with increasing external-swash-plate inclination and the total leakage flow increases with increasing external-swash-plate inclination in one working cycle when the offset distance is constant. It can be seen that the abovementioned parameters are important factors that affect the lubrication characteristics of external return spherical hinge pairs. Therefore, the complex effects of different coupling parameters should be comprehensively considered in the design of the external return mechanism.

摘要

外回程机构是应用于轴向柱塞泵的机械结构,为研究其润滑特性,基于外斜盘倾角和偏距影响 下的外回程球铰副相对运动速度矢量方程,推导出适用于外回程球铰副的Reynolds 方程,对比分析了 不同工况下外回程球铰副的摩擦润滑特性。结果表明:当外斜盘倾角一定时,外回程机构一个工作循 环中最大油膜压力的最大值和总摩擦功率均随着转速的增加而增加、随着偏距的增加而减少;而偏距 的变化对轴向泄露流量的影响甚微。当偏距一定时,一个工作循环中最大油膜压力的最大值随着外斜 盘倾角的增加而减少,总轴向泄露流量随着偏距的增加而增加。由此可知,以上参数是影响外回程球 铰副润滑特性的重要因素。因此在外回程机构设计时,需综合考虑不同参数耦合作用下复杂影响。

Similar content being viewed by others

Abbreviations

- β :

-

External swash plate inclination (°)

- β 1 :

-

The angle between O-x1 and the O-x axis (°)

- b f :

-

Offset distance (m)

- R :

-

Radius of external retainer plate (m)

- R M :

-

Radius of external spherical hinge (m)

- B :

-

Width of external retainer plate (m)

- B 1 :

-

The distance from the point Q to the right end face of the external retainer plate (m)

- B 2 :

-

The distance from the point Q to the left end face of the external retainer plate (m)

- ω b :

-

Angular velocity of the external spherical hinge (rad/s)

- ω r :

-

Instantaneous angular velocity of the external return plate (rad/s)

- ω :

-

Angular velocity of the pump/motor shaft (rad/s)

- m:

-

Intercept an arbitrary small fluid element

- m1 :

-

A contact point between external retainer plate and external spherical hinge

- u r :

-

The velocity components in the direction of r (m/s)

- u θ :

-

The velocity components in the direction of θ (m/s)

- u φ :

-

The velocity components in the direction of φ(m/s)

- r :

-

The distance from any point m in the contact oil film between the external retainer plate and external spherical hinge to the center of the external spherical hinge (m)

- ζ :

-

The distance from the outer surface of external retainer plate to the small fluid element m (m)

- τ θ :

-

Fluid shear stress component in the θ direction (MPa)

- τ φ :

-

Fluid shear stress component in the θ direction (MPa)

- c :

-

Radius clearance (m)

- ε :

-

Eccentricity

- h :

-

Film thickness (m)

- η :

-

Lubricating oil viscosity (Pa·s)

- \(\overline {{F_p}}\) :

-

Loading capacity of oil film

- \(\overline {{F_\varphi}} \) :

-

Friction of oil film

- μ :

-

Friction coefficient of oil film

- P φ :

-

Dimensionless oil film friction power

- \({{\bar Q}_\theta}\) :

-

Dimensionless axial leakage flow

- p 0 :

-

Environment pressure (MPa)

- P :

-

Dimensionless pressure of oil film

- p :

-

Pressure of oil film (MPa)

- n :

-

Pump-shaft speed (r/min)

- ε x :

-

Axial eccentricity

- ε y :

-

Radial eccentricity

- beat:

-

Relaxation factor

- ρ :

-

The constant fluid (oil) density (kg·m−3)

References

TANG He-sheng, YIN Yao-bao, ZHANG Yang, LI Jing. Parametric analysis of thermal effect on hydrostatic slipper bearing capacity of axial piston pump [J]. Journal of Central South University, 2016, 23(2): 333–343. DOI: https://doi.org/10.1007/s11771-016-3078-0.

XING Ming-ming, ZHOU Li-li, ZHAO Yan, XUE Kai-feng, ZHANG Cheng-mao. Fluid characteristic of multiphase fluid in annular space between pump barrel and plunger [J]. Journal of Central South University, 2019, 26(5): 1327–1341. DOI: https://doi.org/10.1007/s11771-019-4090-y.

LI Jing-xiang, MENG Xing-wang, DONG Peng, ZHAO Sheng-dun. Design and analysis of an axial flux permanent magnet motor for the direct drive radial piston pump [J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2019, 233(19, 20): 7077–7088. DOI: https://doi.org/10.1177/0954406219869970.

HAIDAK G, WANG Dong-yun, E Shi-ju. Research on the thermo-elastic deformation and fracture mechanism of the slipper retainer in the axial piston pumps and motors [J]. Engineering Failure Analysis, 2019, 100: 259–272. DOI: https://doi.org/10.1016/j.engfailanal.2019.02.041.

LYU Fei, ZHANG Jun-hui, SUN Guang-ming, XU Bing, PAN Min, HUANG Xiao-chen, XU Hao-gong. Research on wear prediction of piston/cylinder pair in axial piston pumps [J]. Wear, 2020, 456–457: 203338. DOI: https://doi.org/10.1016/j.wear.2020.203338.

ZHANG Jun-hui, CHAO Qun, XU Bing, PAN Min, WANG Qian-nan, CHAN Yuan. Novel three-piston pump design for a slipper test rig [J]. Applied Mathematical Modelling, 2017, 52: 65–81. DOI: https://doi.org/10.1016/j.apm.2017.07.013.

TANG He-sheng, REN Yan, XIANG Jia-wei. A novel model for predicting thermoelastohydrodynamic lubrication characteristics of slipper pair in axial piston pump [J]. International Journal of Mechanical Sciences, 2017, 124–125: 109–121. DOI: https://doi.org/10.1016/j.ijmecsci.2017.03.010.

SHANG Li-zhi, IVANTYSYNOVA M. Scaling criteria for axial piston machines based on thermo-elastohydrodynamic effects in the tribological interfaces [J]. Energies, 2018, 11(11): 3210. DOI: https://doi.org/10.3390/en11113210.

TANG He-sheng, REN Yan, ZHANG Xiang-lei. Tribological performance of MoS2 coating on slipper pair in axial piston pump [J]. Journal of Central South University, 2020, 27(5): 1515–1529. DOI: https://doi.org/10.1007/s11771-020-4387-x.

WANG Zhao-qiang, HU Shan, JI Hong, WANG Zhen, LIU Xin-tan. Analysis of lubricating characteristics of valve plate pair of a piston pump [J]. Tribology International, 2018, 126: 49–64. DOI: https://doi.org/10.1016/j.triboint.2018.05.008.

WANG Zhao-qiang, XU Yan-fei, HU Shan, JI Hong, YANG Jian. Research on lubrication mechanism with fluid-solid coupling of port plate pair in swash plate axial piston pump[J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2020, 234(4): 515–527. DOI: https://doi.org/10.1177/1350650119872888.

DENG Hai-shun, WANG Hai-feng, WANG Qing-chun, WANG Chun-yan, WANG Tao. A swash-plate axial piston pump/motor compacting device [P]. CN107575357A, 2018. (in Chinese)

XIANG Ding-han, WANG Chun-yan, DONG Wei-feng. Structural optimization and friction and wear behavior of a radial spherical plain bearing [J]. Tribology, 2004, 24(6): 564–567. DOI: https://doi.org/10.3321/j.issn:1004-0595.2004.06.018. (in Chinese)

LU Jian-jun, QIU Ming, LI Ying-chun. Wear life models for self-lubricating radial spherical plain bearings [J]. Journal of Mechanical Engineering, 2015, 51(11): 56–63. DOI: https://doi.org/10.3901/JME.2015.11.056. (in Chinese)

XUE Ya-hong, CHEN Ji-gang, GUO Su-min, MENG Qing-liang, LUO Jun-ting. Finite element simulation and experimental test of the wear behavior for self-lubricating spherical plain bearings [J]. Friction, 2018, 6(3): 297–306. DOI: https://doi.org/10.1007/s40544-018-0206-x.

FANG Xin, ZHANG Chun-hua, CHEN Xun, WANG Ya-shun, TAN Yuan-yuan. Newly developed theoretical solution and numerical model for conformal contact pressure distribution and free-edge effect in spherical plain bearings [J]. Tribology International, 2015, 84: 48–60. DOI: https://doi.org/10.1016/j.triboint.2014.11.020.

QIU Ming, LI Ying-chun, CHEN Long, BAI Yao-xing. Effects of rare earth treatment on tribological properties of self-lubricating spherical plain bearings [J]. Wear, 2013, 305(1, 2): 274–279. DOI: https://doi.org/10.1016/j.wear.2012.12.021.

TANG Zhan-qi, LIU Xiao-jun, LIU Kun. Effect of surface texture on the frictional properties of grease lubricated spherical plain bearings under reciprocating swing conditions [J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2017, 231(1): 125–135. DOI: https://doi.org/10.1177/1350650116649117.

HE Wei, HE Jun-chao, XIONG Wei-ling. Lubrication theory research of spherical fixed set bearing in new roller bit on the spherical coordinates [J]. Lubrication Engineering, 2016, 41(10): 63–67. DOI: https://doi.org/10.3969/j.issn.0254-0150.2016.09.012. (in Chinese)

TANG Zhan-qi, LIU Kun, WANG Lei, LIU Xiao-jun. Numerical analysis of grease lubrication for radial spherical plain bearings in rotation and swing motion [J]. Applied Mathematics and Mechanics, 2015, 36(2): 207–219. DOI: https://doi.org/10.3879/j.issn.1000-0887.2015.02.010. (in Chinese)

WANG Qing-chun. Kinematics and friction lubrication analysis in the external return mechanism of piston pump/motor [D]. Huainan: Anhui University of Science and Technology, 2019. DOI: https://doi.org/10.26918/d.cnki.ghngc.2019.000002. (in Chinese)

XU Bing, HU Min, ZHANG Jun-hui, MAO Ze-bing. Distribution characteristics and impact on pump’s efficiency of hydro-mechanical losses of axial piston pump over wide operating ranges [J]. Journal of Central South University, 2017, 24(3): 609–624. DOI: https://doi.org/10.1007/s11771-017-3462-4.

XU Bing, LI Chun-guang, XU Shu-sheng. Research on the relative motion between the ball guider and retainer with in axial piston pump based on virtual prototype [J]. Machine Tool & Hydraulics, 2010, 38(14): 24–26+50. DOI: https://doi.org/10.3969/j.issn.1001-3881.2010.14.008. (in Chinese)

LIU Hong, HU Ji-bing, PENG Zeng-xiong, ZHAO Hong-mei. Effects of hold down device on the slipper’s dynamic characteristics [J]. Transactions of Beijing Institute of Technology, 2017, 37(3): 233–238. DOI: CNKI:SUN:BJLG.0.2017-03-003. (in Chinese)

DENG Hai-shun, HU Cong, WANG Qing-chun, WANG Lei, WANG Chuan-li. Friction and wear analysis of the external return spherical bearing pair of axial piston pump/motor [J]. Mechanics & Industry, 2020, 21(1): 104. DOI: https://doi.org/10.1051/meca/2019072.

WANG Tao, MAO Ming, TANG Shou-sheng. Research on lubrication mechanism of retaining spherical pair of variable displacement axial piston pump [J]. Acta Armamentarii, 2017, 38(3): 11–19. DOI: CNKI:SUN:BIGO.0.2017-03-002. (in Chinese)

DENG Hai-shun, WANG Qing-chun, WANG Hai-feng, WANG Chuan-li. Relative motion relation in the external return spherical bearing pair of a balanced double-row axial piston pump [J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2019, 233(11): 3858–3872. DOI: https://doi.org/10.1177/0954406218805114.

DENG Hai-shun, WANG Lei, GUO Yong-cun, ZHANG Yu, WANG Chuan-li. Analysis of the hydrodynamic lubrication characteristics of the external return spherical bearing pair of an axial piston pump/motor [J]. Mathematical Problems in Engineering, 2020: 1–14. DOI: https://doi.org/10.1155/2020/4902927.

GOENKA P. K., BOOKER J. F. Spherical bearings: static and dynamic analysis via the finite element method [J]. Journal of Lubrication Technology, 1980, 102(3): 308–318. DOI: https://doi.org/10.1115/1.3251522.

CAO Zhong-wen. Research on Hydrodynamic Lubrication of Crankshaft Main Bearings in Internal Combustion Engines [D]. Shanxi: North University of China, 2012. DOI: https://doi.org/10.7666/d.D316506. (in Chinese)

Author information

Authors and Affiliations

Contributions

WANG Lei and DENG Hai-shun provided the concept and edited the draft of manuscript. WANG Lei and HU Cong conducted the literature review and wrote the first draft of the manuscript. WANG Lei, GUO Yong-chun and WANG Chuan-li edited the draft of manuscript.

Corresponding author

Additional information

Conflict of interest

WANG Lei, DENG Hai-shun, GUO Yong-chun, WANG Chuan-li, and HU Cong declare that they have no conflict of interest.

Foundation item: Project(GXXT-2019-048) supported by the University Synergy Innovation Program of Anhui Province, China; Project(51575002) supported by the National Natural Science Foundation of China; Project(gxbjZD11) supported by the Top-Notch Talent Program of University (Profession) in Anhui Province, China

Rights and permissions

About this article

Cite this article

Wang, L., Deng, Hs., Guo, Yc. et al. Lubrication characteristics of external return spherical hinge pair of axial piston pump or motor under combined action of inclination and offset distance. J. Cent. South Univ. 28, 2375–2393 (2021). https://doi.org/10.1007/s11771-021-4776-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4776-9

Key words

- axial piston motor or pump

- external return mechanism

- external swash plate inclination

- offset distance

- lubrication performance