Abstract

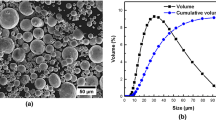

The almost completely dense copper was prepared by ultrafine copper powder prepared with both methods of electrolysis and novel water-gas atomization through cold isostatic pressing (CIP) and sintering under atmospheric hydrogen. Fine copper powder possesses the higher sintering driving force, thereby promoting shrinkage and densification during the sintering process. The grain size of sintered samples by electrolytic copper powder is smaller than that prepared by the atomized copper powder, and the twin crystals are particularly prone to forming in the former sintered microstructure due to the raw powder with low oxygen content and high residual stress originating from the CIP process. The relative density of samples by electrolytic and atomized powder at 1000 °C sintering temperature achieves 99.3% and 97.4%, respectively, significantly higher than that of the powder metallurgy copper parts reported in the literature. Correspondingly, the ultimate tensile strength and yield strength of samples by both kinds of copper powder are approximately similar, while the elongation of the sintered sample by the electrolytic powder (60%) is apparently higher than the atomized powder (44%). The superior performance of samples fabricated by electrolytic powder is inferred from the full density and low oxygen level for there is no cuprous oxide in the grain boundaries.

摘要

本文采用电解法和水气联合雾化法制备出超细铜粉,通过冷等静压、氢气烧结获得全致密铜。 细铜粉具有较高的烧结驱动力,促进烧结收缩和致密化。电解铜粉烧结样品的晶粒尺寸小于雾化铜粉, 且容易形成孪晶,这是由于电解铜粉氧含量低,冷等静压过程使粉末产生较高残余应力。在1000 °C 烧结温度下,电解铜粉和雾化铜粉烧结体的相对密度分别达到99.3%和97.4%,高于文献报道的粉末 冶金铜零件。两种粉末制备的烧结铜的抗拉强度和屈服强度接近,但电解铜粉烧结样品的延伸率(60%) 高于水气联合雾化铜粉的烧结样品(44%)。电解铜粉烧结样品的晶界中不含氧化亚铜,因此具有高的 密度和低的氧含量,最终获得优异的性能。

Similar content being viewed by others

References

AGHAMIRI S M S, OONO N, UKAI S, KASADA R, NOTO H, HISHINUMA Y, MUROGA T. Microstructure and mechanical properties of mechanically alloyed ODS copper alloy for fusion material application [J]. Nuclear Materials and Energy, 2018, 15: 17–22. DOI: https://doi.org/10.1016/j.nme.2018.05.019.

ALTENBERGER I, KUHN H A, MÜLLER H R. Material properties of high-strength beryllium-free copper alloys [J]. International Journal of Materials and Product Technology, 2015, 50(2): 124–146. DOI: https://doi.org/10.1504/IJMPT.2015.067820.

PALOMA H M, XIANZHANG L, RUOYU X, MINGYU Z, IAN A K, ROBERT J Y. Copper/graphene composites: A review [J]. Journal of Materials Science, 2019, 54: 12236–12289. DOI: https://doi.org/10.1007/s10853-019-03703-5.

JANKOVIĆ Z. Electrical and thermal properties of poly (methylmetacrylate) composites filled with electrolytic copper powder [J]. International Journal of Electrochemical Science, 2018, 13: 45–57. DOI: https://doi.org/10.20964/2018.01.24.

FILIZ B C. The role of catalyst support on activity of copper oxide nanoparticles for reduction of 4-nitrophenol [J]. Advanced Powder Technology, 2020, 31(9): 3845–3859. DOI: https://doi.org/10.1016/j.apt.2020.07.026.

YENWISET S, YENWISET T. Effect of the molten metal stream’s shape on particle size distribution of water atomized metal powder [J]. Engineering Journal, 2016, 20(1): 187–196. DOI: https://doi.org/10.4186/ej.2016.20.1.187.

ALVAREZ K L, MARTÍN J, BURGOS N. Structural and magnetic properties of amorphous and nanocrystalline Fe-Si-B-P-Nb-Cu alloys produced by gas atomization [J]. Journal of Alloys and Compounds, 2019, 810: 151754. DOI: https://doi.org/10.1016/j.jallcom.2019.151754.

HOU Long, LI Ming-rui, JIANG Chao, FAN Xing-du. Thermal and magnetic properties of Fe(Co)BCCu amorphous alloys with high saturation magnetization of 1.77 T [J]. Journal of Alloys and Compounds, 2021, 856: 157071. DOI: https://doi.org/10.1016/j.jallcom.2020.157071.

PAVLOV E A, UDALOVA T A, GRIGOREVA T F. Preparing ultradisperse copper powder via the mechanochemical reduction of copper oxides by magnesium [J]. Bulletin of the Russian Academy of Sciences Physics, 2018, 82(5): 574–577. DOI: https://doi.org/10.3103/S1062873818050234.

LEDFORD C, ROCK C, CARRIERE P. Characteristics and processing of hydrogen-treated copper powders for EB-PBF additive manufacturing [J]. Applied Sciences, 2019, 9(19): 3993. DOI: https://doi.org/10.3390/app9193993.

WENDEL J, MANCHILI S K, HRYHA E. Reduction of surface oxide layers on water-atomized iron and steel powder in hydrogen: Effect of alloying elements and initial powder state [J]. Thermochimica Acta, 2020, 692: 178731. DOI: https://doi.org/10.1016/j.tca.2020.178731.

KARLSSON H, NYBORG L, BERG S. Surface chemical analysis of prealloyed water atomised steel powder [J]. Powder Metallurgy, 2005, 48(1): 51–58. DOI: https://doi.org/10.1179/0032589005X37675.

KIM T, OH J M, CHO G H. Surface and internal deoxidation behavior of titanium alloy powder deoxidized by Ca vapor: Comparison of the deoxidation capability of solid solution and intermetallic titanium alloys [J]. Applied Surface Science, 2020, 534: 147623. DOI: https://doi.org/10.1016/j.apsusc.2020.147623.

JUDITH M, YANNICK C, LOÏC P, BENJAMIN V, CLAUDE G. Spark plasma sintering and hydrogen pre-annealing of copper nanopowder [J]. Materials Science and Engineering A, 2015, 621: 61–67. DOI: https://doi.org/10.1016/j.msea.2014.10.040.

STENZEL D, SCHWARZER C, SCHNEPF M. Characterization of alternative sinter materials for power electronics [C]// 2019 22nd European Microelectronics and Packaging Conference & Exhibition (EMPC). 2019: 1–8. DOI: https://doi.org/10.23919/EMPC44848.2019.8951880.

LI Ke-wei, GAO Fei. Heterogeneity of grain refinement and texture formation during pulsed electric current sintering of conductive powder: A case study in copper powder [J]. Advanced Powder Technology, 2018, 29(12): 3385–3393. DOI: https://doi.org/10.1016/j.apt.2018.09.018.

ABE J O, POPOOLA A P I, POPOOLA O M. Consolidation of Ti6Al4V alloy and refractory nitride nanoparticles by spark plasma sintering method: Microstructure, mechanical, corrosion and oxidation characteristics [J]. Materials Science and Engineering A, 2020, 773: 138920. DOI: https://doi.org/10.1016/j.msea.2020.138920.

HIGASHI M, KANNO N. Effect of initial powder particle size on the hot workability of powder metallurgy Ni-based superalloys [J]. Materials & Design, 2020, 194: 108926. DOI: https://doi.org/10.1016/j.matdes.2020.108926.

JIANG R, BULL D, PROPRENTNER D. Effects of oxygen-related damage on dwell-fatigue crack propagation in a P/M Ni-based superalloy: From 2D to 3D assessment [J]. International Journal of Fatigue, 2017, 99: 175–186. DOI: https://doi.org/10.1016/j.ijfatigue.2017.03.003.

SEVOSTYANOV M A, KOLMAKOV A G, SERGIYENKO K V. Mechanical, physical-chemical and biological properties of the new Ti-30Nb-13Ta-5Zr alloy [J]. Journal of Materials Science, 2020, 55(29): 14516–14529. DOI: https://doi.org/10.1007/s10853-020-05020-8.

HIRSCH H H. Improving conductivity of copper PM parts by pretreatment of green compact [J]. Powder Metallurgy, 1979, 22(2): 49–61. DOI: https://doi.org/10.1179/pom.1979.22.2.49.

GUSCHLBAUER R, BURKHARDT A K, FU Z. Effect of the oxygen content of pure copper powder on selective electron beam melting [J]. Materials Science and Engineering A, 2020, 779: 139106. DOI: https://doi.org/10.1016/j.msea.2020.139106.

ZHOU Xiao-long, LI Chen, CAO Han-xing, YU Jie, QIU Guang-huai, WANG Li-hui. Effects of emulsified asphalt on the mechanical and tribological properties of copper/graphite composites [J]. Materials Research Express, 2019, 6(5): 056515. DOI: https://doi.org/10.1088/2053-1591/aafeb7.

MINETA T, SAITO T, YOSHIHARA T. Structure and mechanical properties of nanocrystalline silver prepared by spark plasma sintering [J]. Materials Science and Engineering A, 2019, 754: 258–264. DOI: https://doi.org/10.1016/j.msea.2019.03.101.

CHING N T, HOE C C K, HONG T S, GHOBAKHLOO M. Case study of lean manufacturing application in a die casting manufacturing company [J]. AIP Conference Proceedings, 2015, 1660(1): 090007. DOI: https://doi.org/10.1063/1.4915851.

GIERL C. Reactions between ferrous powder compacts and atmospheres during sintering-An overview [J]. Powder Metallurgy, 2020, 63(4): 237–253. DOI: https://doi.org/10.1080/00325899.2020.1810427.

ZHANG M X, KELLY P M. The morphology and formation mechanism of pearlite in steels [J]. Materials Characterization, 2009, 60(6): 545–554. DOI: https://doi.org/10.1016/j.matchar.2009.01.001.

BARROS L, POLETTO J, NEIS P. Influence of copper on automotive brake performance [J]. Wear, 2019, 426: 741–749. DOI: https://doi.org/10.1016/j.wear.2019.01.055.

SINGH G, PANDEY P M. Experimental investigations into mechanical and thermal properties of rapid manufactured copper parts [J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2020, 234(1): 82–95. DOI: https://doi.org/10.1177/0954406219875483.

ASTM B962-17. Standard test methods for density of compacted or sintered powder metallurgy (PM) products using Archimedes’ principle [S]. US, 2017.

SINGH G, PANDEY P M. Topological ordered copper graphene composite foam: fabrication and compression properties study [J]. Materials Letters, 2019, 257: 126712. DOI: https://doi.org/10.1016/j.matlet.2019.126712.

COLLET R, LE G S, CHARLOT F. Oxide reduction effects in SPS processing of Cu atomized powder containing oxide inclusions [J]. Materials Chemistry & Physics, 2016, 173: 498–507. DOI: https://doi.org/10.1016/j.matchemphys.2016.02.044.

WENDEL J, MANCHILI S K, HRYHA E. Sintering behaviour of compacted water-atomised iron powder: Effect of initial state and processing conditions [J]. Powder Metallurgy, 2020, 63(5): 1–11. DOI: https://doi.org/10.1080/00325899.2020.1833138.

GERMAN R M. History of sintering: Empirical phase [J]. Powder Metallurgy, 2013, 56(2): 117–123. DOI: https://doi.org/10.1179/1743290112Y.0000000025.

SCOTT G D. Radial distribution of the random close packing of equal spheres [J]. Nature, 1962, 194: 956–957. DOI: https://doi.org/10.1038/194956a0.

MASON G. Radial distribution functions from small packings of spheres [J]. Nature, 1968, 217: 733–735. DOI: https://doi.org/10.1038/217733a0.

ATWATER M A, LUCKENBAUGH T L, HORNBUCKLE B C. Advancing commercial feasibility of intraparticle expansion for solid state metal foams by the surface oxidation and room temperature ball milling of copper [J]. Journal of Alloys and Compounds, 2017, 724: 258–266. DOI: https://doi.org/10.1016/j.jallcom.2017.07.029.

COLLET R, GALLET S, CHARLOT F. Oxide reduction effects in SPS processing of Cu atomized powder containing oxide inclusions [J]. Materials Chemistry and Physics, 2016, 173: 498–507. DOI: https://doi.org/10.1016/j.matchemphys.2016.02.044.

NEKOUIE R K, RASHCHI F, JODA N N. Effect of organic additives on synthesis of copper nano powders by pulsing electrolysis [J]. Powder Technology, 2013, 237: 554–561. DOI: https://doi.org/10.1016/j.powtec.2012.12.046.

AVRAMOVIĆ L, MAKSIMOVIĆ V M, BAŠČAREVIĆ Z. Influence of the shape of copper powder particles on the crystal structure and some decisive characteristics of the metal powders [J]. Metals, 2019, 9(1): 56–59. DOI: https://doi.org/10.3390/met9010056.

NIKOLIĆ N D, ŽIVKOVIĆ P M, PAVLOVIĆ M G. Overpotential controls a morphology of electrolytically produced copper dendritic forms [J]. Journal of the Serbian Chemical Society, 2019, 84(11): 1209–1220. DOI: https://doi.org/10.2298/JSC190522066N.

SEIFI R, HOSSEINI R. Experimental study of fatigue crack growth in raw and annealed pure copper with considering cyclic plastic effects [J]. Theoretical and Applied Fracture Mechanics, 2018, 94: 1–9. DOI: https://doi.org/10.1016/j.tafmec.2017.12.003.

Funding

Project(92066205) supported by the National Natural Science Foundation of China; Project(2019-Z10) supported by the State Key Lab for Advanced Metals and Materials of China; Project(FRF-MP-20-52) supported by the Fundamental Research Funds for the Central Universities, China

Author information

Authors and Affiliations

Contributions

LI Pei and CHEN Cun-guang contributed equally to this work. CHEN Cun-guang and LI Pei conducted the literature review and wrote the draft of the manuscript. QIN Qian, LU Tian-xing and SHAO Yan-ru analyzed the measured data. YANG Fang and HAO Jun-jie edited the draft of manuscript. GUO Zhi-meng provided the concept. All authors replied to reviewers’ comments and revised the final version.

Corresponding author

Additional information

Conflict of interest

LI Pei, CHEN Cun-guang, QIN Qian, LU Tianxing, SHAO Yan-ru, YANG Fang, HAO Jun-jie and GUO Zhi-meng declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Li, P., Chen, Cg., Qin, Q. et al. Sintering microstructure and properties of copper powder prepared by electrolyzation and atomization. J. Cent. South Univ. 28, 1966–1977 (2021). https://doi.org/10.1007/s11771-021-4745-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4745-3