Abstract

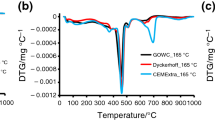

To understand the effect of steam curing temperature on the hydrate and microstructure of hardened cement paste, several measuring methods including X-ray diffraction (XRD), atomic absorption spectroscopy (ASS), ion chromatography, conductivity meter, alternating-current impedance spectroscopy and nuclear magnetic resonance (NMR) are employed to investigate the hydration characteristics, pore solution composition and conductivity, resistivity and pore structure during the steam curing process. Experimental results show that steam curing promotes the hydration process, greatly raises the resistivity, and decreases the porosity of specimen at early age. Compared with being treated at 45 °C, higher temperature leads to a fast decomposition of ettringite at initial stage of the constant temperature treatment period, which improves the relative content and ionic activity of the conductive ions in pore solution. Furthermore, the number of pores larger than 200 nm increases significantly, which reduces the resistivity of the hardened cement paste. Cement paste treated at 45 °C has a more stable and denser microstructure with less damages.

摘要

为了解蒸汽养护温度对硬化水泥浆体水化物相及孔隙结构的影响, 采用X 射线衍射, 原子吸收 光谱, 离子色谱, 电导率仪, 核磁共振, 交流阻抗等方法研究了在蒸汽养护过程中水泥浆体的水化特 征, 孔溶液组成与导电特性, 基体电阻率以及孔隙结构。试验结果表明, 蒸汽养护促进了水化过程, 大幅度提高了基体早期电阻率并降低了孔隙率。与在45 °C 养护温度下相比, 在恒温养护阶段初期, 更高的养护温度导致钙矾石快速分解, 从而提高了孔溶液中导电离子的相对含量和离子活度。此外, 大于200 nm 的孔数量显著增加, 降低了硬化水泥浆体的电阻率。45 °C 养护温度下的水泥浆体微观结 构较稳定且致密, 产生的内部损伤较小。

Similar content being viewed by others

References

JIN Qin-hua, DENG Min, HAN Su-fen. Investigation of deteriorated concrete railway ties [J]. Cement and Concrete Research, 1996, 26(7): 999–1006. DOI: https://doi.org/10.1016/0008-8846(96)00086-5.

LOTHENBACH B, WINNEFELD F, ALDER C, WIELAND E, LUNK P. Effect of temperature on the pore solution, microstructure and hydration products of Portland cement pastes [J]. Cement and Concrete Research, 2007, 37(4): 483–491. DOI: https://doi.org/10.1016/j.cemconres.2006.11.016.

BA Ming-fang, QIAN Chun-xiang, GUO Xin-jun, HAN Xiang-yang. Effects of steam curing on strength and porous structure of concrete with low water/binder ratio [J]. Construction and Building Materials, 2011, 25(1): 123–128. DOI: https://doi.org/10.1016/j.conbuildmat.2010.06.049.

MA Kun-lin, LONG Guang-cheng, XIE You-jun. A real case of steam-cured concrete track slab premature deterioration due to ASR and DEF [J]. Case Studies in Construction Materials, 2017, 6: 63–71. DOI: https://doi.org/10.1016/j.cscm.2016.12.001.

XIANG Yu, XIE You-jun, LONG Guang-cheng. Volume deformation characteristics of concrete mixture during thermal curing process [C]// International Conference on Materials Science and Manufacturing Engineering. EDP Sciences Press, 2018: 01008. DOI: https://doi.org/10.1051/matecconf/201925301008.

LONG Guang-cheng, HE Zhi-min, OMRAN A. Heat damage of steam curing on the surface layer of concrete [J]. Magazine of Concrete Research, 2012, 64(11): 995–1004. DOI: https://doi.org/10.1680/macr.11.00164.

SHI Jin-yan, LIU Bao-ju, WU Xiang, TAN Jin-xia, DAI Jing-dan, JI Rou-jia. Effect of steam curing on surface permeability of concrete: Multiple transmission media [J]. Journal of Building Engineering, 2020, 32: 101475. DOI: https://doi.org/10.1016/j.jobe.2020.101475.

SHI Jin-yan, LIU Bao-ju, ZHOU Feng, SHEN Shuai, DAI Jing-dan, JI Rou-jia, TAN Jin-xia. Heat damage of concrete surfaces under steam curing and improvement measures [J]. Construction and Building Materials, 2020, 252: 119104. DOI: https://doi.org/10.1016/j.conbuildmat.2020.119104.

PATEL H H, BLAND C H, POOLE A B. The microstructure of concrete cured at elevated temperatures [J]. Cement and Concrete Research, 1995, 25(3): 485–490. DOI: https://doi.org/10.1016/0008-8846(95)00036-C.

MEI Jun-peng, MA Bao-guo, TAN Hong-bo, LI Hai-nan, LIU Xiao-hai, JIANG Wen-bin, ZHANG Ting, GUO Yu-lin. Influence of steam curing and nano silica on hydration and microstructure characteristics of high volume fly ash cement system [J]. Construction and Building Materials, 2018, 171: 83–95. DOI: https://doi.org/10.1016/j.conbuildmat.2018.03.056.

WANG Meng, XIE You-jun, LONG Guang-cheng, MA Cong, ZENG Xiao-hui. Microhardness characteristics of high-strength cement paste and interfacial transition zone at different curing regimes [J]. Construction and Building Materials, 2019, 221: 151–162. DOI: https://doi.org/10.1016/j.conbuildmat.2019.06.084.

WANG Meng, XIE You-jun, LONG Guang-cheng, MA Cong, ZENG Xiao-hui, QIANG Fu. The impact mechanical characteristics of steam-cured concrete under different curing temperature conditions [J]. Construction and Building Materials, 2020, 241: 118042. DOI: https://doi.org/10.1016/j.conbuildmat.2020.118042.

DETWILER R, KJELLSEN K, GJORV O. Resistance to chloride intrusion of concrete cured at different temperatures [J]. ACI Materials Journal, 1991, 88(1): 19–24. DOI: https://doi.org/10.14359/2326.

GESOGLU M, GONEYISI E, ALI B, MERMERDAS K. Strength and transport properties of steam cured and water cured lightweight aggregate concretes [J]. Construction and Building Materials, 2013, 49: 417–424. DOI: https://doi.org/10.1016/j.conbuildmat.2013.08.042.

MA Kun-lin, HE Jiong-huang, LONG Guang-cheng, DANG Han-fei, XIE You-jun. Steam-curing temperature effect and its influence on heat damage of cement-based material [J]. Materials Report, 2017, 31(12): 171–176. DOI: https://doi.org/10.11896/j.issn.1005-023X.2017.023.025. (in Chinese)

SHI Jin-yan, LIU Bao-ju, HE Zhi-hai, WU Xiang, TAN Jinxia, CHEN Jia-zhuo, JIANG Jun-yi. Properties evolution of high-early-strength cement paste and interfacial transition zone during steam curing process [J]. Construction and Building Materials, 2020, 252: 119095. DOI: https://doi.org/10.1016/j.conbuildmat.2020.119095.

HOU Wei, LIU Zan-qun, HE Fu-qiang, HUANG Ju, ZHOU Jin. Sulfate diffusion in calcium sulphoaluminate mortar [J]. Construction and Building Materials, 2020, 234: 117312. DOI: https://doi.org/10.1016/j.conbuildmat.2019.117312.

ZHANG Yan-rong, KONG Xiang-ming. Influences of superplasticizer, polymer latexes and asphalt emulsions on the pore structure and impermeability of hardened cementitious materials [J]. Construction and Building Materials, 2014, 53: 392–402. DOI: https://doi.org/10.1016/j.conbuildmat.2013.11.104.

DONG Bi-qin, LI Gui, ZHANG Jian-chao, LIU Yu-qing, XING Feng, HONG Shu-xian. Non-destructive tracing on hydration feature of slag blended cement with electrochemical method [J]. Construction and Building Materials, 2017, 149: 467–473. DOI: https://doi.org/10.1016/j.conbuildmat.2017.05.042.

WANG Hui, ZHANG Ai-lian, ZHANG Lin-chun, WANG Qian, HAN Yan, LIU Jun-zhe, GAO Xiao-jian, SHI Fei-ting, LIN Xue-yan, FENG Li-yu. Hydration process of rice husk ash cement paste and its corrosion resistance of embedded steel bar [J]. Journal of Central South University, 2020, 27(11): 3464–3476. DOI: https://doi.org/10.1007/s11771-020-4559-8.

SONG Guang-ling. Equivalent circuit model for AC electrochemical impedance spectroscopy of concrete [J]. Cement and Concrete Research, 2000, 30(11): 1723–1730. DOI: https://doi.org/10.1016/S0008-8846(00)00400-2.

ZHOU Chun-sheng, REN Fang-zhou, WANG Zhen-di, CHEN Wei, WANG Wei. Why permeability to water is anomalously lower than that to many other fluids for cement-based material? [J]. Cement and Concrete Research, 2017, 100: 373–384. DOI: https://doi.org/10.1016/j.cemconres.2017.08.002.

ZHOU Chun-sheng, REN Fang-zhou, ZENG Qiang, XIAO Li-zhi, WANG Wei. Pore-size resolved water vapor adsorption kinetics of white cement mortars as viewed from proton NMR relaxation [J]. Cement and Concrete Research, 2018, 105: 31–43. DOI: https://doi.org/10.1016/j.cemconres.2017.12.002.

SAHU S, THAULOW N. Delayed ettringite formation in Swedish concrete railroad ties [J]. Cement and Concrete Research, 2004, 34(9): 1675–1681. DOI: https://doi.org/10.1016/j.cemconres.2004.01.027.

HE Zhi-min, LONG Guang-cheng, XIE You-jun, LIU Jun-zhe. Surface layer degradation effect of steam-cured concrete [J]. Journal of Building Materials, 2014, 17(6): 994–1001. DOI: https://doi.org/10.3969/j.issn.1007-9629.2014.06.010. (in Chinese)

QIAN Ru-sheng, ZHANG Yun-sheng, ZHANG Yu, YANG Yong-gan. Relationships between liquid ion concentration and electrical conductivity during the early hydration of cement-fly ash system [J]. Materials Review, 2018, 32(12): 2066–2071. (in Chinese

WANG Yong, YUAN Qiang, DENG De-hua, YE Tao, FANG Lei. Measuring the pore structure of cement asphalt mortar by nuclear magnetic resonance [J]. Construction and Building Materials, 2017, 137: 450–458. DOI: https://doi.org/10.1016/j.conbuildmat.2017.01.109.

ZHANG Mao-hua, LI Hui. Pore structure and chloride permeability of concrete containing nano-particles for pavement [J]. Construction and Building Materials, 2011, 25(2): 608–616. DOI: https://doi.org/10.1016/j.conbuildmat.2010.07.032.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Foundation item

Projects(U1534207, 11790283, 51878583) supported by the National Natural Science Foundation of China

Contributors

XIE You-jun and LONG Guang-cheng provided the concept and edited the draft of manuscript. XIANG Yu implemented the experiment and wrote the first draft of the manuscript. HE Fu-qiang provided the experiment instrument and advised on the analysis of the experiment result.

Conflict of interest

XIANG Yu, XIE You-jun, LONG Guang-cheng, and HE Fu-qiang declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Xiang, Y., Xie, Yj., Long, Gc. et al. Hydration phase and pore structure evolution of hardened cement paste at elevated temperature. J. Cent. South Univ. 28, 1665–1678 (2021). https://doi.org/10.1007/s11771-021-4725-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4725-7