Abstract

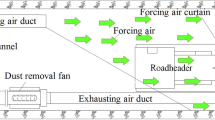

In order to control the dust pollution produced by air leg rock drill in the trolley area during the excavation of long-distance single ended tunnel, the full-scale physical model of working face was established by using FLUENT software, and the numerical simulation analysis of tunnel drilling ventilation and dust removal parameters was carried out. The results show that it is difficult to control the dust pollution of the face by conventional ventilation, and the drilling dust is distributed in the range of 10 m from the face; after the introduction of the long pressure and short suction ventilation scheme, when the ratio of compressed air volume to exhaust air volume is 0.72, the height of the pressure fan is 2.5 m, the distance between the pressure fan and the palm face is 20 m, and the exhaust fan is 12 m away from the palm, the dust concentration control efficiency of the working face is increased by about 60%. Therefore, in the similar long-distance single head tunnel construction, it is appropriate to adopt the dust removal method of long-distance short suction and exhaust fan to ensure the working environment.

摘要

为控制长距离独头隧道掘进过程中台车区气腿凿岩机产生的粉尘污染, 采用Fluent 软件建立了 工作面全尺寸几何模型, 对隧道钻孔通风除尘参数进行了数值模拟分析。结果表明, 采用常规通风 方式, 很难控制掌子面粉尘污染, 钻孔粉尘遍布在距掌子面10 m 范围内; 引入长压短抽式通风方案, 当压风量与排风量之比为0.72, 压风机高度设为2.5 m, 压风机距掌心面20 m, 排风机距掌面12 m 时, 对掌子面工作时的粉尘浓度控制效率提高约60%。因此, 在类似长距离的独头隧道施工中, 宜采 用长压短抽及排风风机配合的除尘方式, 以保证良好的工作环境。

Similar content being viewed by others

References

ABBEY D E, NISHINO N, MCDONNELL W F, BURCHETTE R J, KNUTSEN S F, LAWRENCE B W, YANG J X. Long-term inhalable particles and other air pollutants related to mortality in nonsmokers [J]. American Journal of Respiratory and Critical Care Medicine, 1999, 159(2): 373–382. DOI: https://doi.org/10.1164/ajrccm.159.2.9806020.

ZHENG Y P, FENG C G, JING G X, QIAN X M, LI X J, LIU Z Y, HUANG P. A statistical analysis of coal mine accidents caused by coal dust explosions in China [J]. Journal of Loss Prevention in the Process Industries, 2009, 22(4): 528–532. DOI: https://doi.org/10.1016/j.jlp.2009.02.010.

NIU W, JIANG Z A, TIAN D M. Numerical simulation of the factors influencing dust in drilling tunnels: its application [J]. Mining Science and Technology, 2011, 21(1): 11–15. DOI: https://doi.org/10.1016/j.mstc.2010.12.009. (in Chinese)

ZHANG Q, ZHOU G, QIAN X M, YUAN M Q, SUN Y L, WANG D. Diffuse pollution characteristics of respirable dust in fully-mechanized mining face under various velocities based on CFD investigation [J]. Journal of Cleaner Production, 2018, 184: 239–250. DOI: https://doi.org/10.1016/j.jclepro.2018.02.230.

NIE W, WEI W L, MA X, LIU Y H, PENG H T, LIU Q. The effects of ventilation parameters on the migration behaviors of head-on dusts in the heading face [J]. Tunnelling and Underground Space Technology, 2017, 70: 400–408. DOI: https://doi.org/10.1016/j.tust.2017.09.017.

WANG Xiao-zhen, JIANG Zhong-an, WANG Shan-wen, LIU Yi. Numerical simulation of distribution regularities of dust concentration during the ventilation process of coal roadway driving [J]. Journal of China Coal Society, 2007, 32(4): 386–390. DOI: https://doi.org/10.1016/S1872-2067(07)60020-5. (in Chinese)

JI Y L, REN T, WYNNE P, WAN Z J, MA Z Y, WANG Z M. A comparative study of dust control practices in Chinese and Australian longwall coal mines [J]. International Journal of Mining Science and Technology, 2016, 26(2): 199–208. DOI: https://doi.org/10.1016/j.ijmst.2015.12.004.

CHEN L J, LI P C, LIU G M, CHENG W M, LIU Z X. Development of cement dust suppression technology during shotcrete in mine of China-A review [J]. Journal of Loss Prevention in the Process Industries, 2018, 28(55): 232–242. DOI: https://doi.org/10.1016/j.jlp.2018.07.001.

FANG Y, YAO Z G, LEI S. Air flow and gas dispersion in the forced ventilation of a road tunnel during construction [J]. Underground Space, 2019, 4(2): 168–179. DOI: https://doi.org/10.1016/j.undsp.2018.07.002.

REN T, ZHANG J, WEI J P. Applications of water infusion for dust control in underground coal mines—A critical review [C]// Proceedings of the 11th International Mine Ventilation Congress. 2018: 219–230. DOI: https://doi.org/10.1007/978-981-13-1420-9_19.

ZHOU G, ZHANG Q, BAI R N, FAN T, WANG G. The diffusion behavior law of respirable dust at fully mechanized caving face in coal mine: CFD numerical simulation and engineering application [J]. Process Safety and Environmental Protection, 2017, 106: 117–128. DOI: https://doi.org/10.1016/j.psep.2016.12.005.

ZHOU G, FENG B, YIN W J, WANG J Y. Numerical simulations on airflow-dust diffusion rules with the use of coal cutter dust removal fans and related engineering applications in a fully-mechanized coal mining face [J]. Powder Technology, 2018, 339: 354–367. DOI: https://doi.org/10.1016/j.powtec.2018.07.078.

HE J F, SUN B X, LIANG Y P, LUO Y J. Research on suction capacity and dust suppression performance of a reverse circulation air hammer in tunnel drilling [J]. Tunnelling and Underground Space Technology, 2018, 71: 391–402. DOI: https://doi.org/10.1016/j.tust.2017.09.008.

REMPEL D, ANTONUCCI A, BARR A, COOPER M R, MARTIN B, NEITZEL R L. Pneumatic rock drill vs. electric rotary hammer drill: Productivity, vibration, dust, and noise when drilling into concrete [J]. Applied Ergonomics, 2019, 74: 31–36. DOI: https://doi.org/10.1016/j.apergo.2018.08.005.

LIU Z, WANG X L, CHENG Z F, SUN R R, ZHANG A L. Simulation of construction ventilation in deep diversion tunnels using Euler-Lagrange method [J]. Computers & Fluids, 2014, 105: 28–38. DOI: https://doi.org/10.1016/j.compfluid.2014.09.016.

ZHANG H, SUN J C, LIN F, WANG L. Optimization on energy saving ventilation of gallery-type combined construction shaft exhaust in extra long tunnel [J]. Procedia Engineering, 2017, 205: 1777–1784. DOI: https://doi.org/10.1016/j.proeng.2017.10.030

von GLEHN F H, BLUHM S J. Practical aspects of the ventilation of high-speed developing tunnels in hot working environments [J]. Tunnelling and Underground Space Technology, 2000, 15(4): 471–475. DOI: https://doi.org/10.1016/S0886-7798(01)00016-5.

WANG X L, LIU X P, SUN Y F, AN J, ZHANG J, CHEN H C. Construction schedule simulation of a diversion tunnel based on the optimized ventilation time [J]. Journal of Hazardous Materials, 2009, 165(1-3): 933–943. DOI: https://doi.org/10.1016/j.jhazmat.2008.10.115.

YU H M, CHENG W M, WU L R, WANG H, XIE Y. Mechanisms of dust diffuse pollution under forced-exhaust ventilation in fully-mechanized excavation faces by CFD-DEM [J]. Powder Technology, 2017, 317: 31–47. DOI: https://doi.org/10.1016/j.powtec.2017.04.045.

CAI P, NIE W L, HUA Y, WEI W L, JIN H. Diffusion and pollution of multi-source dusts in a fully mechanized coal face [J]. Process Safety and Environmental Protection, 2018, 118: 93–105. DOI: https://doi.org/10.1016/j.psep.2018.06.011.

REN T, WANG Z W, COOPER G. CFD modelling of ventilation and dust flow behaviour above an underground bin and the design of an innovative dust mitigation system [J]. Tunnelling and Underground Space Technology, 2014, 41: 241–254. DOI: https://doi.org/10.1016/j.tust.2014.01.002.

WANG Y P, JIANG Z A, CHEN J S, CHEN J H, WANG M. Study of high-pressure air curtain and combined dedusting of gas water spray in multilevel ore pass based on CFD-DEM [J]. Advanced Powder Technology, 2019, 30(9): 1789–1804. DOI: https://doi.org/10.1016/j.apt.2019.05.019.

HU S Y, FENG G R, REN X Y, XU G, CHANG P, WANG Z, ZHANG Y T, LI Z, GAO Q. Numerical study of gas-solid two-phase flow in a coal roadway after blasting [J]. Advanced Powder Technology, 2016, 27(4): 1607–1617. DOI: https://doi.org/10.1016/j.apt.2016.05.024.

CHEN X L, WHEELER C A, DONOHUE T J, MCLEAN R, ROBERTS A W. Evaluation of dust emissions from conveyor transfer chutes using experimental and CFD simulation [J]. International Journal of Mineral Processing, 2012, 110: 101–108. DOI: https://doi.org/10.1016/j.minpro.2012.04.008.

HUA Y, NIE W, WEI W L, LIU Q, LIU Y H, PENG H T. Research on multi-radial swirling flow for optimal control of dust dispersion and pollution at a fully mechanized tunnelling face [J]. Tunnelling and Underground Space Technology, 2018, 79: 293–303. DOI: https://doi.org/10.1016/j.tust.2018.05.018.

MA Z F, DAI H H. 3CFD numerical simulation of improving airflow state in upcast corner of coalface by spinning and direct airflow ventilation [J]. Journal of China Coal Society, 2008, 33(11): 1279–1282. DOI: https://doi.org/10.1016/S1872-5791(08)60057-3.

TASCÓN A, AGUADO P J. CFD simulations to study parameters affecting dust explosion venting in silos [J]. Powder Technology, 2015, 272: 132–141. DOI: https://doi.org/10.1016/j.powtec.2014.11.031.

ZHANG Hui. Study on dust production mechanism and dust control technology of dry drilling in coal lane [D]. Xiangtan: Hunan University of Science and Technology, 2017. (in Chinese)

LEE D K. A computational flow analysis for choosing the diameter and position of an air duct in a working face [J]. Journal of Mining Science, 2011, 47(5): 664–674. DOI: https://doi.org/10.1134/S1062739147050169.

SU S, CHEN H W, TEAKLE P, XUE S. Characteristics of coal mine ventilation air flows [J]. Journal of Environmental Management, 2008, 86(1): 44–62. DOI: https://doi.org/10.1016/j.jenvman.2006.11.025.

WALLACE K, PROSSER B, STINNETTE J D. The practice of mine ventilation engineering [J]. International Journal of Mining Science and Technology, 2015, 25(2): 165–169. DOI: https://doi.org/10.1016/j.ijmst.2015.02.001.

LIU Q, NIE W, HUA Y, PENG H T, LIU C Q, WEI C H. Research on tunnel ventilation systems: Dust diffusion and pollution behaviour by air curtains based on CFD technology and field measurement [J]. Building and Environment, 2019, 147: 444–460. DOI: https://doi.org/10.1016/j.buildenv.2018.08.061.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

Project(51874016) supported by the National Natural Science Foundation of China

Contributors

WANG Ya-peng conducted the literature review and wrote the first draft of the manuscript. JIANG Zhong-an provided the concept and MEN Li-guo analyzed the measured data.

Conflict of interest

WANG Ya-peng, JIANG Zhong-an and MEN Li-guo declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Jiang, Za., Wang, Yp. & Men, Lg. Ventilation control of tunnel drilling dust based on numerical simulation. J. Cent. South Univ. 28, 1342–1356 (2021). https://doi.org/10.1007/s11771-021-4704-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4704-z