Abstract

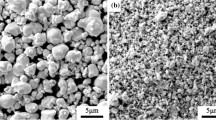

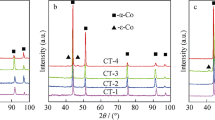

For developing new binder phase with high performance, Co-Ni-Fe alloy was used as binder in cemented carbides. The mechanical properties of WC-CoNiFe and WC-Co cemented carbides with different grain sizes were studied. The results show that the reprecipitation of WC-CoNiFe is inhibited compared with that of WC-Co during sintering process, and the grains in WC-CoNiFe cemented carbides are more of smooth shape, resulting in a slightly lower hardness and higher transverse rupture strength. With the increase of the grain size, the hardness of the two cemented carbides decreases, and the transverse rupture strength increases. However, the slope values of K in Hall-Petch relationship are higher in WC-CoNiFe than those in WC-Co, indicating the high toughness of medium entropy alloy Co-Ni-Fe.

摘要

为了开发高性能的新型粘结相, Co-Ni-Fe 合金被用作硬质合金中的粘结剂. 本文研究了不同晶 粒尺寸的 WC-CoNiFe 与 WC-Co 的力学性能的差异. 结果表明, 与 WC-Co 相比, 在烧结过程中 的变大, 两种硬质合金的硬度变低, 抗弯强度上升. 而且, 在霍尔-佩奇关系中, WC-CoNiFe 的斜率 值 高于 K 高于 WC-Co, 表明中熵合金 Co-Ni-Fe 具有较高的韧性.

Similar content being viewed by others

References

KONYASHIN I, HLAWATSCHEK S, RIES B, LACHMANN F, VUKOVIC M. Cobalt capping on WC–Co hardmetals. Part I: A mechanism explaining the presence or absence of cobalt layers on hardmetal articles during sintering [J]. International Journal of Refractory Metals & Hard Materials, 2014, 42(1): 142–150.

NAN L, HE Y, JIN Z. Enhanced mechanical properties and oxidation resistance of tungsten carbide-cobalt cemented carbides with aluminum nitride additions [J]. Ceramics International, 2017, 43(8): 6603–6606.

GARCIA J. Influence of Fe–Ni–Co binder composition on nitridation of cemented carbides [J]. International Journal of Refractory Metals & Hard Materials, 2012, 30(1): 114–120.

ZHAO Z, LIU J, TANG H, MA X, ZHAO W. Investigation on the mechanical properties of WC–Fe–Cu hard alloys [J]. Journal of Alloys & Compounds, 2015, 632: 729–734.

FERNANDES C M, VILHENA L M, PINHO C M S, OLIVEIRA F J, SOARES E, SACRAMENTO J, SENOS A M R. Mechanical characterization of WC–10 wt% AISI 304 cemented carbides [J]. Materials Science and Engineering A, 2014, 618(4): 629–636.

LINDER D, HOU Z, XIE R, HEDSTRÖM P, STRÖM V, HOLMSTRÖM E, BORGENSTAM A. A comparative study of microstructure and magnetic properties of a Ni Fe cemented carbide: Influence of carbon content [J]. International Journal of Refractory Metals and Hard Materials, 2019, 80: 181–187.

CHANG S H, CHEN S L. Characterization and properties of sintered WC–Co and WC–Ni–Fe hard metal alloys [J]. Journal of Alloys and Compounds, 2014, 585: 407–413.

SU W, WEN Y, ZHANG Q. Effects of Ni and Cu additions on microstructures, mechanical properties and wear resistances of ultra-coarse grained WC–6Co cemented carbides [J]. International Journal of Refractory Metals and Hard Materials, 2018, 70(1): 176–183.

ZHANG F G, ZHU X P, LEI M K. Surface characterization and tribological properties of WC-Ni cemented carbide irradiated by high intensity pulsed electron beam [J]. Vacuum, 2017, 137(3): 119–124.

CAI X, ZHONG L, XU Y, LI X, LIU M. Microstructure and fracture toughness of a WC-Fe cemented carbide layer produced by a diffusion-controlled reaction [J]. Surface and Coatings Technology, 357(1): 784–793.

CHEN C S, YANG C C, CHAI H Y, YEH J W, CHAU J L H. Novel cermet material of WC/multi-element alloy [J]. International Journal of Refractory Metals and Hard Materials, 2014, 43(12): 200–204.

ZHOU R, CHEN G, LIU B, WANG J W, HAN L L, LIU Y. Microstructures and wear behaviour of (FeCoCrNi)1−x(WC)x, high entropy alloy composites [J]. International Journal of Refractory Metals and Hard Materials, 2018, 75: 56–62.

LUO W, LIU Y, SHEN J. Effects of binders on the microstructures and mechanical properties of ultrafine WC-10%AlxCoCrCuFeNi composites by spark plasma sintering [J]. Journal of Alloys and Compounds, 2019, 791: 540–549.

GAO Y, LUO B H, HE K J, ZHANG W W, BAI Z H. Effect of Fe/Ni ratio on the microstructure and properties of WC-Fe-Ni-Co cemented carbides [J]. Ceramics International, 2018, 44(2): 2030–2041.

CHANG S H, CHANG M H, HUANG K T. Study on the sintered characteristics and properties of nanostructured WC–15 wt% (Fe–Ni–Co) and WC–15 wt% Co hard metal alloys [J]. Journal of Alloys and Compounds, 2015, 649: 89–95.

GILLE G, BREDTHAUER J, GRIES B, MENDE B, HEINRICH W. Advanced and new grades of WC and binder powder–their properties and application [J]. International Journal of Refractory Metals & Hard Materials, 2000, 18(2, 3): 87–102.

BS EN ISO 3327:2009. Hardmetals-determination of transverse rupture strength [S]. Brussels: European Committee for Standardization, 2009.

ZHANG L, TIAN W, CHEN Y, LIU T, ZHANG H D, ZHOU L, ZHU J F. Fine platelet-like grained WC–Co cemented carbides: Preparation, characterization, properties and application in PVD coating substrates [J]. International Journal of Refractory Metals and Hard Materials, 2017, 64(Complete): 135–142.

ROEBUCK B, GEE M, BENNETE G, MORRELL R. Measurement good practice guide No. 20–Mechanical tests for hardmetals [R]. National Physics Laboratory, 2009 (ISSN 1368-6550).

LLANES L, TORRES Y, ANGLADA M. On the fatigue crack growth behavior of WC–Co cemented carbides: Kinetics description, microstructural effects and fatigue sensitivity [J]. Acta Materialia, 2002, 50(9): 2381–2393.

ZHOU P, LIU S, WANG P, XU H, PENG Y, YUAN X, DU Y, ZHANG J, HUANG W. Experimental investigation and thermodynamic assessment of the Hf-Mn system [J]. Journal of Phase Equilibria and Diffusion, 2011, 33(1): 20–28.

CHANG S H, CHANG P Y. Investigation into the sintered behavior and properties of nanostructured WC–Co–Ni–Fe hard metal alloys [J]. Materials Science and Engineering A, 2014, 606: 150–156.

CHANG S H, CHEN S L. Characterization and properties of sintered WC–Co and WC–Ni–Fe hard metal alloys [J]. Journal of Alloys and Compounds, 2014, 585: 407–413.

HERBER R P, SCHUBERT W D, LUX B. Hardmetals with “rounded” WC grains [J]. International Journal of Refractory Metals & Hard Materials, 2006, 24(5): 360–364.

KIM S, HAN S H, PARK J K, KIM H E. Variation of WC grain shape with carbon content in the WC–Co alloys during liquid-phase sintering [J]. Scripta Materialia, 2003, 48(5): 635–639.

WITTMANN B, SCHUBERT W D, LUX B. WC grain growth and grain growth inhibition in nickel and iron binder hardmetals [J]. International Journal of Refractory Metals & Hard Materials, 2002, 20(1): 51–60.

ZHAO S, SONG X, ZHANG J, LIU X. Effects of scale combination and contact condition of raw powders on SPS sintered near-nanocrystalline WC–Co alloy [J]. Materials Science and Engineering A, 2008, 473(1, 2): 323–329.

SHON I J, JEONG I K, KO I Y, DOH J M, WOO K D. Sintering behavior and mechanical properties of WC–10Co, WC–10Ni and WC–10Fe hard materials produced by high-frequency induction heated sintering [J]. Ceramics International, 2009, 35(1): 339–344.

EXNER H E, GURLAND J. A review of parameters influencing some mechanical properties of tungsten carbide-cobalt alloys [J]. Powder Metallurgy, 1970, 13(25): 13–31.

GAO Y, LUO B H, BAI Z H, ZHU B, OUYANG S. Effects of deep cryogenic treatment on the microstructure and properties of WC[sbnd]Fe[sbnd]Ni cemented carbides [J]. International Journal of Refractory Metals & Hard Materials, 2016, 58: 42–50.

SCHUBERT W D, FUGGER M, WITTMANN B, USELDINGER R. Aspects of sintering of cemented carbides with Fe-based binders [J]. International Journal of Refractory Metals and Hard Materials, 2015, 49: 110–123.

ARMSTRONGRW. 60 years of Hall-Petch: past to present nano-scale connections [J]. Mater Trans, 2014, 55: 2–12.

ROA J J, JIMÉNEZ-PIQUÉ E, TARRAGÓ, JM, SANDOVAL D A, MATEO A, FAIR J, LLANES L. Hall-Petch strengthening of the constrained metallic binder in WC–Co cemented carbides: Experimental assessment by means of massive nanoindentation and statistical analysis [J]. Materials Science and Engineering A, 2016, 676: 487–491.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51671217) supported by the National Natural Science Foundation of China; Project(2016YFB0700302) supported by the National Key Research and Development Plan of China

Rights and permissions

About this article

Cite this article

Qian, C., Li, K., Guo, Xy. et al. Effect of WC grain size on mechanical properties and microstructures of cemented carbide with medium entropy alloy Co-Ni-Fe binder. J. Cent. South Univ. 27, 1146–1157 (2020). https://doi.org/10.1007/s11771-020-4355-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-020-4355-5

Key words

- cemented carbides

- mechanical properties

- dissolution-reprecipitation

- Hall-Petch relationship

- medium entropy alloy