Abstract

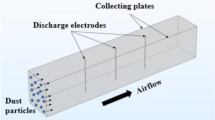

To improve the dust removal performance of the wet electrostatic precipitator (WESP), a flow field optimization scheme was proposed via CFD simulation in different scales. The simplified models of perforated and collection plates were determined firstly. Then the model parameters for the resistance of perforated and collection plates, obtained by small-scale flow simulation, were validated by medium-scale experiments. Through the comparison of the resistance and velocity distribution between simulation results and experimental data, the simplified model is proved to present the resistance characteristics of perforated and collection plates accurately. Numerical results show that after optimization, both the flow rate and the pressure drop in the upper room of electric field regions are basically equivalent to those of the lower room, and the velocity distribution in flue inlet of WESP becomes more uniform. Through the application in practice, the effectiveness and reliability of the optimization scheme are proved, which can provide valuable reference for further optimization of WESP.

摘要

为了提高湿式静电除尘器的除尘性能, 本文提出了一种基于多尺度数值模拟的流场优化方法. 首先, 确定多孔板和收尘板的简化模型; 然后, 得到相关的阻力参数, 并通过中尺度实验进行验证. 将模拟得到的阻力和速度分布与实验数据比较后发现简化模型能够准确地反映多孔板和收尘板的阻力特性. 数值结果表明, 经过优化后, 电场上、下室的流量和压降基本相当, 且烟道入口的速度分布更加均匀. 将优化方案应用于工程实际后发现该方案确实有效可靠, 可为湿式静电除尘器的性能优化提供有价值的参考.

Similar content being viewed by others

References

ŚWIERCZOK A, JĘDRUSIK M. The collection efficiency of ESP model-comparison of experimental results and calculations using deutsch model [J]. Journal of Electrostatics, 2018, 91: 41–47. DOI: https://doi.org/10.1016/j.elstat.2017.12.004.

LI X D, ZHOU C Y, LI J W, LU S Y, YAN J H. Distribution and emission characteristics of filterable and condensable particulate matter before and after a low-low temperature electrostatic precipitator [J]. Environmental Science and Pollution Research, 2019, 26: 13. DOI: https://doi.org/10.1007/s11356-019-04570-y.

TANSKI M, BERENDT A, MIZERACZYK J. Closed SDBD-driven two-stage electrostatic precipitator [J]. Journal of Cleaner Production, 2019, 226: 74–84. DOI: https://doi.org/10.1016/j.jclepro.2019.03.280.

KAWADA Y, SHIMIZE H. Development of an electrostatic precipitator with porous carbon electrodes to collect carbon particles [J]. Energies, 2019, 12(14): 2805. DOI: https://doi.org/10.3390/en12142805.

BORDADO M J, QUINTAFERREIRA J C, QUINTAFERREIRA R M. Treatment and use of air pollution control residues from MSW incineration: An overview [J]. Waste Management, 2008, 28(11): 2097–2121. DOI: https://doi.org/10.1016/j.wasman.2007.08.030.

MCCANN D. New and upgraded electrostatic precipitators for recovery boilers [J]. Journal of Science & Technology for Forest Products and Processes, 2017, 6(3): 15–18.

PARK H W, PARK D W. Removal kinetics for gaseous NO and SO2 by an aqueous NaClO2 solution mist in a wet electrostatic precipitator [J]. Environmental Technology Letters, 2017, 38(7): 835–843. DOI: https://doi.org/10.1080/09593330.2016.1213770.

SAIYASITPANICH P, KEENER T C, LU M M, LIANG F Y, KHANG S J. Control of diesel gaseous and particulate emissions with a tube-type wet electrostatic precipitator [J]. Journal of the Air & Waste Management Association, 2008, 58(10): 1311–1317.

SU L P, DU Q, WANG Y D, DONG H M, GAO J M, WANG M, DONG P. Purification characteristics of fine particulate matter treated by a self-flushing wet electrostatic precipitator equipped with a flexible electrode [J]. Journal of the Air & Waste Management Association, 2018, 68(7): 725–736. DOI: https://doi.org/10.1080/10962247.2018.1460635.

YANG Z D, ZHENG C H, ZHANG X F, CHANG Q Y, WENG W G, WANG Y, GAO X. Highly efficient removal of sulfuric acid aerosol by a combined wet electrostatic precipitator [J]. RSC Advances, 2018, 8(1): 59–66.

CAO R J, TAN H Z, XIONG Y Y, MIKULCIC H, VUJANOVIC M, WANG X B, DUIĆ N. Improving the removal of particles and trace elements from coal-fired power plants by combining a wet phase transition agglomerator with wet electrostatic precipitator [J]. Journal of Cleaner Production, 2017, 161: 1459–1465. DOI: https://doi.org/10.1039/C7RA11520B

SAIYASITPANICH P, KEENER T C, LU M M, KHANG S J, EVANS D E. Collection of ultrafine diesel particulate matter (DPM) in cylindrical single-stage wet electrostatic precipitators [J]. Environmental Science & Technology, 2006, 40(24): 7890–7894. DOI: https://doi.org/10.1021/es060887k.

CHANG J, DONG Y, YAN J, LI B, MA C Y. Performance test of a new wet ESP with flexible collection Electrodes [C]// International Conference on Bioinformatics & Biomedical Engineering. IEEE, 2010. DOI: https://doi.org/10.1109/ICBBE.2010.5516443.

CHEN T M, TSAI C J, YAN S Y, LI S N. An efficient wet electrostatic precipitator for removing nanoparticles, submicron and micron-sized particles [J]. Separation & Purification Technology, 2014, 136: 27–35. DOI: https://doi.org/10.1016/j.seppur.2014.08.032.

YANG Z D, ZHENG C H, LIU S J, GUO Y S, LIANG C S, WANG Y, HU D Q, GAO X. A combined wet electrostatic precipitator for efficiently eliminating fine particle penetration [J]. Fuel Processing Technology, 2018, 180: 122–129. DOI: https://doi.org/10.1016/j.fuproc.2018.08.013.

YANG Z D, ZHENG C H, ZHANG X F, ZHOU H, SILVA A A, LIU C Y, SNYDER B, WANG Y, GAO X. Challenge of SO3 removal by wet electrostatic precipitator under simulated flue gas with high SO3 concentration [J]. Fuel, 2018, 217: 597–604. DOI: https://doi.org/10.1016/j.fuel.2017.12.125.

QIU Z Z, LI P, PAN W G, REN J X, WANG W H, WU J, ZHU Q Z. Modeling of the velocity profile and experimental study on velocity uniformity in the electrostatic precipitator [C]// International Conference on Power Engineering. Hangzhou, 2007. DOI: https://doi.org/10.1007/978-3-540-76694-0_85.

HAQUE S M E, RASUL M G, KHAN M M K, DEEV A V, SUBASCHANDAR N. Influence of the inlet velocity profiles on the prediction of velocity distribution inside an electrostatic precipitator [J]. Experimental Thermal and Fluid Science, 2009, 33(2): 322–328. DOI: https://doi.org/10.1016/j.expthermflusci.2008.09.010.

TU G, SONG Q, YAO Q. Experimental and numerical study of particle deposition on perforated plates in a hybrid electrostatic filter precipitator [J]. Powder Technology, 2017, 321: 143–153. DOI: https://doi.org/10.1016/j.powtec.2017.08.021.

YE X L, SU Y B, GUO B Y, YU A B. Multi-scale simulation of the gas flow through electrostatic precipitators [J]. Applied Mathematical Modelling, 2016, 40(21, 22): 9514–9526. DOI: https://doi.org/10.1016/j.apm.2016.06.023.

GUO B Y, YANG S Y, XING M, DONG K J, YU A B, GUO J. Toward the development of an integrated multiscale model for electrostatic precipitation [J]. Industrial & Engineering Chemistry Research, 2013, 52(33): 11282–11293. DOI: https://doi.org/10.1021/ie303466g.

GUO B Y, HOU Q F, YU A B, LI L F, GUO J. Numerical modelling of the gas flow through perforated plates [J]. Chemical Engineering Research & Design, 2013, 91(3): 403–408. DOI: https://doi.org/10.1016/j.cherd.2012.10.004.

LUO K, LI Y, ZHENG C H, GAO X, FAN J R. Numerical simulation of temperature effect on particles behavior via electrostatic precipitators [J]. Applied Thermal Engineering, 2015, 88: 127–139. DOI: https://doi.org/10.1016/j.applthermaleng.2014.11.078.

YANG K, LI Q, DING Z J, XIAO L C. CFD-based simulation study on producer gas explosion in an electrostatic precipitation [J]. Process Safety Progress, 2016, 35(1): 96–102. DOI: https://doi.org/10.1002/prs.11743.

GAO F D, WANG D X, WANG H D. Numerical analysis and verification of the gas jet from aircraft engines impacting a jet blast deflector [J]. Chinese Journal of Mechanical Engineering, 2018, 31(1): 86. DOI: CNKI:SUN:YJXB.0.2018-05-013.

LEE S D. Impacts of surrounding building layers in CFD wind simulations [J]. Energy Procedia, 2017, 122: 50–55. DOI: https://doi.org/10.1016/j.egypro.2017.07.313.

CHOI B S, FLETCHER C A J. Computation of particle transport in an electrostatic precipitator [J]. Journal of Electrostatics, 1997, 40–41: 413–418. DOI: https://doi.org/10.1016/s0304-3886(97)00080-6.

SKODRAS G, KALDIS S P, SOFIALIDIS D, FALTIS O, GRAMMELIS P, SAKELLAROPOULOS G P. Particulate removal via electrostatic precipitators-CFD simulation [J]. Fuel Processing Technology, 2006, 87(7): 623–631.

TU J H, YUAN W F, ZHU P J. Computation of flow field distribution in electrostatic precipitator equal resistance simulation [J]. Journal of Environmental Engineering, 2004, 28: 37–39.

SAHIN B. Pressure losses in an isolated perforated plate and jets emerging from the perforated plate [J]. International Journal of Mechanical Sciences, 1989, 31: 51–61. DOI: https://doi.org/10.1016/0020-7403(89)90118-5.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ye, Xl., Wang, S., Zhang, H. et al. Process simulation and optimization of flow field in wet electrostatic precipitator. J. Cent. South Univ. 27, 132–143 (2020). https://doi.org/10.1007/s11771-020-4283-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-020-4283-4

Key words

- process simulation

- optimization

- flow field

- wet electrostatic precipitator

- perforated plate

- collection plate