Abstract

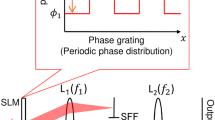

Beam shaping is required for semiconductor lasers to achieve high optical fiber coupling efficiency in many applications. But the positioning errors on optics may reduce beam shaping effects, and then lead to low optical fiber coupling efficiency. In this work, the positioning errors models for the single emitter laser diode beam shaping system are established. Moreover, the relationships between the errors and the beam shaping effect of each shapers are analysed. Subsequently, the relationship between the errors and the optical fiber coupling efficiency is analysed. The result shows that position errors in the Z axis direction on the fast axis collimator have the greatest influence on the shaping effect, followed by the position errors in the Z axis direction on the converging lens, which should be strictly suppressed in actual operation. Besides, the position errors have a significant influence on the optical fiber coupling efficiency and need to be avoided.

摘要

半导体激光器在许多应用中为获得高光纤耦合效率需要进行光束整形。但光学系统若存在定位 误差将会降低光束的整形效果,以导致光纤耦合效率降低。本文建立了单发射激光器二极管光束整形 系统的定位误差模型。然后分析了个整形光器件的误差和光束整形效果的关系。还分析了误差和光纤 耦合效率的关系。结果表明,快轴准直透镜在Z 轴方向上存在位置误差对光束整形效果的影响最大, 其次是会聚透镜在Z 轴方向上的位置误差对光束整形效果的影响,这在实际操作中应严格避免。此外, 光纤存在位置误差对光纤耦合效率影响较大,也需要尽量避免。

Similar content being viewed by others

References

FRIEDRICH D. High power diode lasers: Technology and applications [J]. Proceedings of SPIE-The International Society for Optical Engineering, 2007, 3888: 3888–38162. DOI: 10.1117/12.377093.

MURPHY E. The semiconductor laser: Enabling optical communication [J]. Nature Photonics, 2010, 4(5): 287–1287. DOI: 10.1038/nphoton.2010.107.

FRED M D. Laser beam shaping [J]. Optics & Photonics News, 2003, 14(4): 30–35.

HANNA D C, CLARKSON W A. Two-mirror beam-shaping technique for high-power diode bars [J]. Optics Letters, 1996, 21(6): 375–377. DOI: 10.1364/OL.21.000375.

DICKEY F M, SHEALY D L. Laser beam shaping V [J]. Proc Spie, 2004, 5175(4): 751–760.

LEGER J R, GOLTSOS W C. Geometrical transformation of linear diode-laser arrays for longitudinal pumping of solid-state lasers [J]. IEEE Journal of Quantum Electronics, 1992, 28(4): 1088–1100. DOI:10.1109/3.135232.

LIU X S, ZHAO W, XIONG L L, LIU H. Packaging of high power semiconductor lasers [M]. Heidelberg, Springer, 2014: 107–115. DOI:10.1007/978-1-4614-9263-4.

HEINEMANN S. Fiber-coupled diode lasers and beam-shaped high-power stacks [J]. Proceedings of SPIE-The International Society for Optical Engineering, 1998, 3267: 3267–4116. DOI:10.1117/12.308099.

KÖHLER B, BRAND T, HAAG M, BIESENBACH J. Wavelength stabilized high-power diode laser modules [C]// High-Power Diode Laser Technology and Applications VII. International Society for Optics and Photonics, 2009: 719810–1719810-12. DOI:10.1117/12.809541.

CHIBA K, YAMAGUCHI S, KOBAYASHI T, SAITO Y. Collimation of emissions from a high-power multistripe laser-diode bar with multiprism array coupling and focusing to a small spot [J]. Optics Letters, 1995, 20(8): 898–900. DOI: 10.1364/OL.20.000898.

EHLERS B, DU K, BAUMANN M, TREUSCH H. Beam shaping and fiber coupling of high-power diode laser arrays [C]// Lasers in Material Processing. International Society for Optics and Photonics, 1997: 639–644. DOI: 10.1117/12. 281128.

TIAN Z N, WANG L J, CHEN Q D, JIANG T, QIN L, SUN H B. Beam shaping of edge-emitting diode lasers using a single double-axial hyperboloidal micro-lens [J]. Optics Letters, 2013, 38(24): 5414–7. DOI: 10.1364/OL.38.005414.

XIONG L L, CAI L, ZHENG Y F, LIU H. Slow axis collimation lens with variable curvature radius for semiconductor laser bars [J]. Optics & Laser Technology, 2016, 77: 77–81. DOI: 10.1016/j.optlastec.2015.08.004.

MALACARNE L C, ASTRATH N G C, BAESSO M L. Unified theoretical model for calculating laser-induced wavefront distortion in optical materials [J]. Journal of the Optical Society of America B, 2012, 29(7): 1772–1777. DOI: 10.1364/josab.29.001772.

LIU M, LI B, WANG Y. Accurate determination of subnanoscale deformation with combined laser calorimetry and surface thermal lens technique [J]. Applied Physics Letters, 2009, 94(13): 650. DOI: 10.1063/1.3106630.

FANG F Z, XIONG Z, HU X T. Ultra-precision machining of reflector array for laser diode beam shaping [J]. Optoelectron Lett, 2007, 3(2): 141–143. DOI: 10.1007/s11801-007-7020-4.

LI D X, ZHANG J F, ZHANG Y L, FENG P F. Modeling, identification and compensation for geometric errors of laser annealing table [J]. Journal of Central South University, 2014, 21(3): 904–911. DOI: 10.1007/s11771-014-2017-1.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51475479) supported by the National Natural Science Foundation of China; Project(2017YFB1104800) supported by the National Key Research and Development Program of China; Project(2016GK2098) supported by the Key Research and Development Program of Hunan Province, China; Project(ZZYJKT2017-07) supported by the State Key Laboratory of High Performance Complex Manufacturing, Central South University, China; Project(JMTZ201804) supported by the Key Laboratory for Precision & Non-traditional Machining of Ministry of Education, Dalian University of Technology, China

Rights and permissions

About this article

Cite this article

Yan, Yx., Zheng, Y. & Duan, Ja. Influence of positioning errors of optical shaping components for single emitter laser diode on beam shaping effects. J. Cent. South Univ. 26, 2814–2821 (2019). https://doi.org/10.1007/s11771-019-4215-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-019-4215-3