Abstract

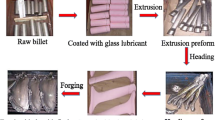

The 4-lobe aluminum alloy helical surface rotors are widely applied in industry, such as superchargers. Generally, the conventional manufacturing processes of aluminum alloy helical surface are time consuming and costly. To make the manufacturing processes more flexible and economical, the forward hot extrusion process is proposed to form the 4-lobe aluminum alloy helical surface rotors. In this work, we implement both simulations and experiments to the forming process of the helical surface, of which the material is 6063 aluminum alloy. The forward hot extrusion process is simulated with finite element method in DEFORM-3D. Based on the simulation method, the influences of different extrusion parameters, such as extrusion temperature, extrusion speed and extrusion ratio, on the extrusion process are studied. According to the numerical simulation results, the optimal case is chosen to carry out the experiment. Furthermore, the experimental results show that the surface is smooth; the toothed fill is full; the twist angle in the length direction is evenly distributed; the value of twist angle is roughly in line with the design angle, which is mainly due to the modified die structure, having a positive and significant effect on the increment of twist angle. Therefore, the twist angle has an increase of about 76%, which verifies the modified die structure.

摘要

四叶铝合金螺旋面转子广泛应用于工业中, 如机械增压器。传统加工铝合金螺旋面的工艺存在 费时和成本高的问题。为了使制造工艺更加灵活和经济, 提出了正向热挤压工艺来成形 4 叶铝合金螺 旋面转子。本文所用的材料为 6063 铝合金, 对螺旋面的成形过程进行了数值仿真和挤压实验。采用 DEFORM-3D 软件对正向热挤压成形过程进行了有限元模拟。在仿真方法的基础上, 研究了不同的挤 压参数, 如挤压温度、挤压速度、挤压比, 对挤压过程的影响。根据数值模拟结果, 选择最优情况进 行挤压实验。实验结果表明, 转子表面光滑;齿形填充饱满;在长度方向上扭转角分布均匀;扭转角 的值与设计角的值基本一致。能够达到这个好结果的主要原因是使用了改进后的模具结构, 对扭转角 的增加有积极而显著的影响, 因此, 扭转角增加了约76%, 验证了改进后模具结构。

Similar content being viewed by others

References

LIU Hou-gen, LI Zhi-bao, LI Cheng-jia. Design and manufacturing research of roots mechanical supercharger new rotors [J]. Modern Manufacturing Engineering, 2014, 8: 112–116. DOI: https://doi.org/10.16731/j.cnki.1671-3133.2014.08.013.

INGLE P D, NARKHEDE B E. A literature survey of methods to study and analyze the gating system design for its effect on casting quality [J]. Materials Today: Proceedings, 2018, 5(2): 5421–5429. DOI: org/https://doi.org/10.1016/j.matpr.2017.12.129.

WEI Wei, JIANG Peng, TANG Yong-fu. Analysis on forging defects of aluminum alloy forging with rib [J]. Forging & Stamping Technology, 2012, 4(37): 18–21. DOI: https://doi.org/10.3969/j.issn.1000-3940.2012.04.004.

FOUAD M, EL-GARAIHY W H, AHMED M M Z, EL-SAYED S M M, SALEM H G. Influence of multi-channel spiral twist extrusion (MCSTE) processing on structural evolution, crystallographic texture and mechanical properties of AA1100 [J]. Materials Science and Engineering: A, 2018, 737: 166–175. DOI: https://doi.org/10.1016/j.msea.2018.09.039.

KUBOKI T, ISHIKAWA M, KAJIKAWA S, MURATA M. An extrusion method of tube with spiral inner fins by utilizing generation of spiral outer fins/grooves [J]. CIRP Annals, 2018, 67: 305–308. DOI: https://doi.org/10.1016/j.cirp.2018.04.023.

IVANISENKO Y, KULAGIN R, FEDOROV V A, MAZILKIN A, SCHERER T, BARETZKY B, HAHN H. High pressure torsion extrusion as a new severe plastic deformation process [J]. Materials Science and Engineering: A, 2016, 664: 247–256. DOI: https://doi.org/10.1016/j.msea.2016.04.008.

CAI Chen, YAN B, LASZLO S T, FUNDENBERGER J J. Microstructure and strain in protrusions formed during severe plastic deformation of aluminum [J]. Materials Letters, 2015, 159: 253–256. DOI: https://doi.org/10.1016/j.matlet.2015.07.008.

CHAUBEY S K, JAIN N K. Exploring WSEM process for manufacturing meso helical and bevel gears [J]. Materials Today: Proceedings, 2018, 5(9): 18552–18561. DOI: https://doi.org/10.1016/j.matpr.2018.06.198.

SNOPIŃŚKI P, TAŃSKI T, MATUS K, MATUS K, RUSZ S. Microstructure, grain refinement and hardness of Al–3%Mg aluminium alloy processed by ECAP with helical die [J]. Archives of Civil and Mechanical Engineering, 2019, 9(2): 287–296. DOI: https://doi.org/10.1016/j.acme.2018.11.003.

ZHANG Yu, YAN Hong-zhi, ZENG Tao. Tooth surface geometry optimization of spiral bevel and hypoid gears generated by duplex helical method with circular profile blade [J]. Journal of Central South University, 2016, 23(3): 544–554. DOI: https://doi.org/10.1007/s11771-016-3101-5.

YANG Guang, ZHANG Kang-sheng, HU Zheng-huan. Feasibility study on screw compressor driven rotor with fixed cross rolling [J]. Journal of Northeastern University, 2015, 12(36): 1785–1789. DOI: 1005-3026(2015)12-1785-05.

KIM J G, LATYPOV M, PARDIS N. Finite element analysis of the plastic deformation in tandem process of simple shear extrusion and twist extrusion [J]. Materials & Design, 2015, 83: 858–865. DOI: https://doi.org/10.1016/j.matdes.2015.06.034.

HWANG Y M, CHANG C N. Hot extrusion of hollow helical tubes of magnesium alloys [J]. Procedia Engineering, 2014, 81: 2249–2254. DOI: https://doi.org/10.1016/j.proeng.2014.10.316.

PARK Y B, YOON J H, YANG D Y. Finite element analysis of steady-state three-dimensional helical extrusion of twisted section using recurrent boundary conditions [J]. International Journal of Mechanical Science, 1994, 36(2): 137–148. DOI: https://doi.org/10.1016/0020-7403(94)90081-7.

PARK Y B, YANG D Y. Investigation into non-steady-state three-dimensional helical extrusion of twisted sections by the rigid-plastic finite element method [J]. Engineering Computations, 1997, 6(14): 649–668. DOI: /https://doi.org/10.1108/02644409710180509.

KHODDAM S, FARHOUMAND A, HODGSON P D. Axi-symmetric forward spiral extrusion, a kinematic and experimental study [J]. Materials Science and Engineering A, 2011, 528: 1023–1069. DOI: https://doi.org/10.1016/j.msea.2010.09.062.

KHODDAM S, FARHOUMAND A, HODGSON P D. A kinematics study of variable lead axisymmetric forward spiral extrusion [J]. Materials Science and Engineering A, 2012, 550: 167–175. DOI: https://doi.org/10.1016/j.mmsea.2012.04.053.

KHODDAM S, FARHOUMAND A, HODGSON P D. Upper-bound analysis of axi-symmetric forward spiral extrusion [J]. Mechanics of Materials, 2011, 43: 684–692. DOI: https://doi.org/10.1016/j.mechmat.2011.07.009.

FARHOUMAND A, HODGSON P D, KHODDAM S. Multiple pass axi-symmetrical forward spiral extrusion of interstitial-free (IF) steel [J]. Materials Science & Engineering A, 2013, 579: 217–225. DOI: https://doi.org/10.1016/j.msea.2013.05.034.

YAGITA T, KUBOKI T, MURATA M. Formability improvement by die-bearing grooves in tube extrusion with spiral inner projections [J]. Procedia Engineering, 2014, 81: 641–646. DOI: https://doi.org/10.1016/j.proeng.2014.10.053.

SAPANATHAN T, KHODDAM S, ZAHIRI S. Spiral extrusion of aluminum/ copper composite for future manufacturing of hybrid rods: A study of bond strength and interfacial characteristics [J]. Journal of Alloys and Compounds, 2013, 571: 85–90. DOI: https://doi.org/10.1016/j.jallcom.2013.03.210.

FREDERIC B B, BACHI F B, HAROUN Y, DIGNE M, CORRE V L. Helical extrusion of unsymmetrical multi-lobed catalyst supports: United State, Patent Pub.No. US2015/0174571AL [P]. 2015-06-25.

KHALIFA N B, TEKKAYA A E. Newest developments on the manufacture of helical profiles by hot extrusion [J]. Journal of Manufacturing Science and Engineering, 2011, 133: 101–108. DOI: https://doi.org/10.1115/1.4005116.

KHALIFA N B, BECKER D, SCHIKORRA M, TEKKAYA A E. Recent developments in the manufacture of complex components by influencing the material flow during extrusion [J]. Journal of Manufacturing Key Engineering Materials, 2008, 367: 55–62. DOI: https://doi.org/10.4028/www.scientific.net/KEM.367.55.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(zzyjkt2014-09) supported by the National Key Laboratory of High Performance and Complex Manufacturing, China; Project(2015GK3006) supported by Key R&D Program of Science and Technology Department of Hunan Province, China

Rights and permissions

About this article

Cite this article

Xia, F., Li, H., Liu, Hg. et al. Forward hot extrusion forming process of 4-lobe aluminum alloy helical surface rotor. J. Cent. South Univ. 26, 2307–2317 (2019). https://doi.org/10.1007/s11771-019-4175-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-019-4175-7