Abstract

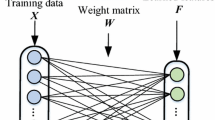

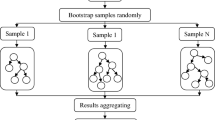

Modern agricultural mechanization has put forward higher requirements for the intelligent defect diagnosis. However, the fault features are usually learned and classified under all speeds without considering the effects of speed fluctuation. To overcome this deficiency, a novel intelligent defect detection framework based on time-frequency transformation is presented in this work. In the framework, the samples under one speed are employed for training sparse filtering model, and the remaining samples under different speeds are adopted for testing the effectiveness. Our proposed approach contains two stages: 1) the time-frequency domain signals are acquired from the mechanical raw vibration data by the short time Fourier transform algorithm, and then the defect features are extracted from time-frequency domain signals by sparse filtering algorithm; 2) different defect types are classified by the softmax regression using the defect features. The proposed approach can be employed to mine available fault characteristics adaptively and is an effective intelligent method for fault detection of agricultural equipment. The fault detection performances confirm that our approach not only owns strong ability for fault classification under different speeds, but also obtains higher identification accuracy than the other methods.

摘要

现代农业机械化对农机使用过程中的故障诊断提出了更高的要求。 然而, 故障特征通常是在所 有转速下进行学习和分类的, 而没有考虑转速波动的影响. 为了克服这一缺陷, 本文提出了一种基于 时频变换的智能故障诊断新框架. 在该框架中, 一种转速下的样本用来训练稀疏滤波, 然后其他转速 下的样本用来测试稀疏滤波的性能. 本文提出的方法包括两个阶段:1)对机械原始振动数据进行短时 傅里叶变换(STFT), 得到时频域信号, 然后利用稀疏滤波模型从时频信号中提取故障特征. 2)基于学 习到的故障特征, 利用softmax 回归对不同的机械健康状况进行分类. 提出方法可以用来自适应的提 取故障特征, 是一种可对农业机械进行有效故障诊断的智能方法. 故障诊断结果表明, 该方法不仅在 不同转速下的故障诊断中下具有较强优势, 而且比其他方法具有更高的分类准确率.

Similar content being viewed by others

References

HE Zheng-jia, CHEN Jin, WANG Tai-yong, CHU Fu-lei. Theory and application of mechanical fault diagnosis [M]. Beijing: Higher Education Press, 2010. (in Chinese)

ZHONG Bing-lin, HUANG Ren. Mechanical fault diagnosis (the third edition) [M]. Beijing: Machinery Industry Press, 2006. (in Chinese)

ZHU Zhong-kui. Research on the application of wavelet analysis in automotive gear transmission fault diagnosis [D]. Hefei: HeFei University of Technology, 2002. DOI: 10.7666/d.y446917. (in Chinese)

JIAO Xin-tao. The wavelet analysis and its application in fault diagnosis of gear box [D]. Guangzhou: South China University of Technology, 2014. DOI: 10.3969/j.issn.1000-3835.2005.05.030. (in Chinese)

PRIETO M D, CIRRINCIONE G, ESPINOSA A G, ORTEGA J A, HENAO H. Bearing fault detection by a novel condition-monitoring scheme based on statistical-time features and neural networks [J]. IEEE Transactions on Industrial Electronics, 2013, 60(8): 3398–3407. DOI: 10. 1109/TIE.2012.2219838.

LI Yong-bo, XU Min-qiang, WANG Ri-xin, HUANG Wen-hu. A new rolling bearing fault diagnosis method based on multiscale permutation entropy and improved support vector machine based binary tree [J]. Measurement, 2016, 77: 80–94. DOI: https://doi.org/10.1016/j.measurement.2015. 08.034.

ZHANG Wei, PENG Gao-liang, LI Chuan-hao, CHEN Yuan-hang, ZHANG Zhu-jun. A new deep learning model for fault diagnosis with good anti-noise and domain adaptation ability on raw vibration signals [J]. Sensors, 2017, 17(2): 425–446. DOI: 10.3390/s17020425.

WANG Xiang, ZHENG Yuan, ZHAO Zhen-zhou, WANG Jin-ping. Bearing fault diagnosis based on statistical locally linear embedding [J]. Sensors, 2015, 15(7): 16225–16247. DOI: 10.3390/s150716225.

JOANNIN C, CHOUVION B, THOUVEREZ E, OUSTY J P, MBAYE M. A nonlinear component mode synthesis met the computation of steady-state vibration in non-conservative systems [J]. Mechanical Systems and Signal Processing, 2017, 83: 75–92. DOI: https://doi.org/10.1016/j.ymssp.2016.05.044.

LI Chuan, SANCHEZ R V, ZURITA G, LOZADA M C, CABRERA D. Rolling element bearing defect detection using the generalized synchrosqueezing transform guided by time-frequency ridge enhancement [J]. ISA Transactions, 2016, 60: 274–284. DOI: 10.1016/j.isatra.2015.10.014.

LI Chuan, SANCHEZ R V, ZURITA G, CERRADE M, CABRERA D. Multimodal deep support vector classification with homologous features and its application to gearbox fault diagnosis [J]. Neurocomputing, 2015, 168: 119–127. DOI: https://doi.org/10.1016/j.neucom.2015.06.008.

XU Dong-wei, WANG Yong-dong, JIA Li-min, ZHANG gui-jun, GUO hai-feng. Real-time road traffic states estimation based on kernel-KNN matching of road traffic spatial characteristics [J]. Journal of Central South University, 2016, 23: 2453–2464. DOI: 10.1007/s11771-016-3304-9.

WIDODO A, YANG B S. Support vector machine in machine condition monitoring and fault diagnosis [J]. Mechanical Systems and Signal Processing, 2008, 21(6): 2560–2574. DOI: https://doi.org/10.1016/j.ymssp.2006.12.007.

SINHA J K, ELBHBAH K. A future possibility of vibration based condition monitoring of rotating machines[J]. Mechanical Systems and Signal Processing, 3013, 34(1, 2): 231–240. DOI: https://doi.org/10.1016/j.ymssp.2012.07.001.

PAYA B A, ESAT II. Artificial neural networks based fault diagnosis of rotating machinery using wavelet transforms as a preprocessor [J]. Mech Syst Signal Process, 2010, 11(5): 751–765. DOI: https://doi.org/10.1006/mssp.1997.0090.

VERMA N K, GUPTA V K, SHARMA M. Intelligent condition based monitoring of rotating machines using sparse auto-encoders [J]. Prognostics and Health Management, IEEE, 2013, 7789(4): 1–7. DOI: 10.1109/ ICPHM.2013. 6621447.

TAMILSELVAN P, WANG Ping-feng. Failure diagnosis using deep belief learning based health state classification [J]. Reliability Engineering & System Safety, 2013, 115(7): 124–135. DOI: https://doi.org/10.1016/j.ress.2013.02.022.

GUO Xiao-jie, CHEN Liang, SHEN Chang-qing. Hierarchical adaptive deep convolution neural network and its application to bearing fault diagnosis [J]. Measurement, 2016, 93: 490–502. DOI: https://doi.org/10.1016/j.measurement.2016.07.054.

JANSSENS O, SLAVKOVIKJ V, VERVISCH B, STOCKMAN K, LOCCUFIER M, VERSTOCKT S. Convolutional neural network based fault detection for rotating machinery [J]. Journal of Sound and Vibration, 2016, 377: 331–345. DOI: https://doi.org/10.1016/j.jsv.2016.05.027.

JIA Feng, LEI Ya-guo, LIN Jing, ZHOU Xin, LU Na. Deep neural networks: A promising tool for fault characteristic mining and intelligent diagnosis of rotating machinery with massive data [J]. Mechanical Systems and Signal Processing, 2016, 72, 73: 303–315. DOI: https://doi.org/10.1016/j.ymssp.2015.10.025.

LI Chuan, SANCHEZ R V, ZURITA G, CERRADE M, CABRERA D. Gearbox fault diagnosis based on deep random forest fusion of acoustic and vibratory signals [J]. Mechanical Systems and Signal Processing, 2016, 76–77: 283–293. DOI: https://doi.org/10.1016/j.ymssp.2016.02.007.

NGIAM J, PANG W K, CHEN Zheng-hao, BHASKAR S, NG A Y. Sparse filtering [J]. Proc Neural Inf Process Syst, 2011, 11: 1125–1133.

LEI Ya-guo, JIA Feng, LIN Jing, XING Sai-bo, DING S X. An intelligent fault diagnosis method using unsupervised feature learning towards mechanical big data [J]. IEEE Trans Ind Electron, 2016, 63(5): 31–37. DOI: 10.1109/TIE.2016.2519325.

LOUGHLIN P J. Methods and applications of time-frequency analysis [J]. Asian Pacific Journal of Allergy & Immunology, 2000, 107(5): 30–36. DOI: https://doi.org/10.1121/1.429126.

LI Y. Theory and application of time-frequency transform [D]. Xi'an: Northwestern Polytechnical University, 2003. DOI: 10.7666/d.y525922. (in Chinese)

GUO Zhen-yu, WANG Z J. An unsupervised hierarchical feature learning framework for one-shot image recognition [J]. IEEE Transactions on Multimedia, 2013, 15(3): 621–632. DOI: 10.1109/TMM.2012.2234729.

HOU Chen-ping, NIE Fei-ping, LI Xue-dong. Joint embedding learning and sparse regression: a framework for unsupervised feature selection [J]. IEEE Transactions on Cybernetics, 2014, 44(6): 793–804. DOI: 10.1109/TCYB. 2013.2272642.

WORDEN K, STASZEWSKI W J, HENSMAN J J. Natural computing for mechanical systems research: A tutorial overview [J]. Mech Syst Signal Process, 2011, 25(1): 4–111. DOI: https://doi.org/10.1016/j.ymssp.2010.07.013.

SHATNAWI Y, AL-KHASSAWENEH M. Fault diagnosis in internal combustion engines using extension neural network [J]. IEEE Trans Ind Electron, 2014, 61(3): 1434–1443. DOI: 10.1109/tie.2013.2261033.

PRIETO M D, CIRRINCIONE G, ESPINOSA A G, ORTEGA J A, HENAO H. Bearing fault detection by a novel condition-monitoring scheme based on statistical-time features and neural networks [J]. IEEE Trans Ind Electron, 2013, 60(8): 3398–3407. DOI: 10.1109/TIE.2012. 2219838.

LIU D C, NOCEDAL J. On the limited memory BFGS method for large scale optimization [J]. Mathematical Programming, 1989, 45(1–3): 503–528. DOI: https://doi.org/10.1007/BF01589116.

JIANG Ming-yang, LIANG Yan-chun, FENG Xiao-yue. Text classification based on deep belief network and softmax regression [J]. Neural Computing & Applications, 2016: 1–10. DOI: https://doi.org/10.1007/s00521-016-2401-x.

MAATEN L, HINTON G. Visualizing data using t-SNE [J]. Journal of Machine Learning Research, 2008, 620(1): 2579–2605.

JIANG Xing-xing, LI Shun-ming, WANG Yong. A novel method for self-adaptive feature extraction using scaling crossover characteristics of signals and combining with LS-SVM for multi-fault diagnosis of gearbox [J]. Journal of Vibro Engineering, 2015, 17(4): 1861–1878.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51675262) supported by the National Natural Science Foundation of China; Project(2016YFD0700800) supported by the National Key Research and Development Program of China; Project(6140210020102) supported by the Advance Research Field Fund Project of China; Project (NP2018304) supported by the Fundamental Research Funds for the Central Universities, China; Project(2017-IV-0008-0045) supported by the National Science and Technology Major Project

Rights and permissions

About this article

Cite this article

Zhang, Zw., Chen, Hh., Li, Sm. et al. A novel sparse filtering approach based on time-frequency feature extraction and softmax regression for intelligent fault diagnosis under different speeds. J. Cent. South Univ. 26, 1607–1618 (2019). https://doi.org/10.1007/s11771-019-4116-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-019-4116-5