Abstract

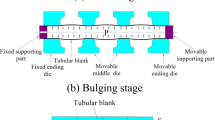

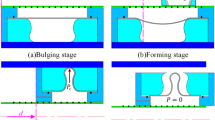

Based on the traditional hydraulic bulging process, an improved hydraulic bulging process with axial feeding in the bulging process was proposed. The finite element simulation and experiment of bellows formed by the traditional and improved hydraulic bulging processes were conducted. The grid strain measurement system analysis results of strain and wall thickness distribution of the metal bellows, obtained from simulation and experiment, show that the maximum thinning rates of the wall thickness under the traditional and improved processes were 15% and 10%, respectively. And the wall thickness distribution of the metal bellows formed with improved process was more uniform. The strain values from the root to crown of the waveform increased gradually. However, the strain values were smaller than those of traditional process due to the axial feeding of the improved process in bulging process.

摘要

基于传统液压胀形工艺, 提出在胀形阶段对坯料轴向进给的推进式液压胀形新工艺。对波纹金 属软管推进式液压胀形新工艺和传统液压胀形工艺进行有限元模拟和实验研究, 并通过网格应变测量 法分析波纹金属软管的应变和壁厚减薄率。模拟和实验结果表明: 传统液压胀形工艺和推进式液压胀 形新工艺的最大壁厚减薄率分别是15%和10%, 且推进式液压胀形工艺的壁厚分布更均匀; 两种工艺 下的应变均从波谷中心区到波峰中心区逐渐增大, 但推进式液压胀形新工艺由于在胀形阶段的轴向进 给, 减小了波纹金属软管成形各区的应变值。

Similar content being viewed by others

References

DAYYANI I, SHAW A D, FLORES E I S, FRISWELL M I. The mechanics of composite corrugated structures: A review with applications in morphing aircraft [J]. Composite Structures, 2015, 133(1): 358–380. DOI: 10.1016/j.compstruct.2015.07. 099.

HACHEMI H, KEBIR H, ROELANDT J M, WINTREBERT E. A study of the braided corrugated hoses: Behavior and life estimation [J]. Materials & Design, 2011, 32(4): 1957–1966. DOI: 10.1016/j.matdes.2010.11.075.

ZHANG W W, CONG S. Failure analysis of SUS304 sheet during hydro-bulging based on GTN ductile damage model [J]. International Journal of Advanced Manufacturing Technology, 2016, 86(1–4): 427–435. DOI 10.1007/s00170-015–8199-3.

KANG B H, LEE M Y, SHON S M, MOON Y H. Forming various shapes of tubular bellows using a single-step hydroforming process [J]. Journal of Materials Processing Technology, 2007, 194(1–3): 1–6. DOI: 10.1016/j.jmatprotec.2007. 02.029.

GUAN K, ZHANG X, GU X, CAI L, XU H, WANG Z. Failure of 304 stainless bellows expansion joint [J]. Engineering Failure Analysis, 2005, 12(3): 387–399. DOI: 10.1016/j.engfailanal.2004. 05.007.

XUE Y H, CHEN K, FAN C J, LUO J T. Deep drawing of cup shell by powder cavity flexible forming technology [J]. Journal of Central South University, 2017, 24(4): 766–772. DOI: 10.1007/s11771-017-3478-9.

ZHANG X, MA Y, ZOU H, TAO S, ZHANG Q, ZHANG E. Experimental study: Correcting the calculation formula for a welded metal bellows’ effective diameter [J]. Sealing Technology, 2016, 2016(10): 7–12. DOI: 10.1016/S1350-4789(16)30326-9.

LIU C, LU K, SHENG L, SONG Y, SU J, SU M. Manufacture and test of seismic bellows for ITER magnet feeder [J]. Fusion Engineering & Design, 2016, 109–111: 515–520. DOI: 10.1016/j.fusengdes.2016.02.065.

BI J, ZHAO C C, BI M M, DU B, CHEN XH, DONG G J. Heat treatment and granule medium internal high-pressure forming of AA6061 tube [J]. Journal of Central South University, 2017, 24(5): 1040–1049. DOI: 10.1007/s11771-017–3507-8.

DONG G J, ZHAO C C, ZHAO J P. Research on technological parameters [J]. Journal of Central South University, 2016, 23(4): 765–777. DOI: 10.1007/s11771-016-3122-0.

SONG L H, HUANG N N, LIN G D, ZHANG W L, MIN L I, GUAN C J. Application of CAE in numerical simulation of bellows forming [J]. Pipeline Technique & Equipment, 2010(4): 35–37. (in Chinese)

LIU J, HUANG W, LI X, LI L. Comparative study on deformation behavior of single and bi-layered U-shaped stainless steel bellows in hydroforming [J]. Forging & Stamping Technology, 2016, 41(5): 24–28. (in Chinese)

LEE S W. Study on the forming parameters of the metal bellows [J]. Journal of Materials Processing Technology, 2002, 130–131(11): 47–53. DOI: 10.1016/S0924-0136(02)00787-2.

FURUSHIMA T, HUNG N Q, MANABE K I, SASAKI O. Development of semi-dieless metal bellows forming process [J]. Journal of Materials Processing Technology, 2013, 213(8): 1406–1411. DOI: 10.1016/j.jmatprotec.2013.03.002.

BAKHSHI-JOOYBARI M, ELYASI M, GORJI A. Numerical and experimental investigation of the effect of the pressure path on forming metallic bellows [J]. Proceedings of the Institution of Mechanical Engineers Part B Journal of Engineering Manufacture, 2010, 224(1): 95–101. DOI: 10.1243/09544054JEM1586.

MIRZAALI M, LIAGHAT G H, NAEINI H M, SEYEDKASHI S M H, SHOJAEE K. Optimization of tube hydroforming process using simulated annealing algorithm [J]. Procedia Engineering, 2011, 10(1): 3012–3019. DOI: 10.1016/j.proeng.2011.04.499.

FARAJI G, MASHHADI M M, NOROUZIFARD V. Evaluation of effective parameters in metal bellows forming process [J]. Journal of Materials Processing Technology, 2009, 209(7): 3431–3437. DOI: 10.1016/j.jmatprotec. 2008.07.057.

SHINDE R A, DR B T P, JOSHI K N. Optimization of tube hydroforming process (without Axial Feed) by using FEA simulations [J]. Procedia Technology, 2016, 23: 398–405. DOI: 10.1016/j.protcy.2016.03.043.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51775479) supported by the National Natural Science Foundation of China; Project(E2017203046) supported by the Natural Science Foundation of Hebei Province, China

Rights and permissions

About this article

Cite this article

Hao, Zl., Xi, Cy., Huang, Zh. et al. Hydraulic bulging process with axial feedings and strain field of U-shaped metal bellows. J. Cent. South Univ. 25, 2712–2721 (2018). https://doi.org/10.1007/s11771-018-3948-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-018-3948-8

Key words

- hydraulic bulging process

- finite element simulation

- thinning rate of wall thickness

- grid strain measurement system