Abstract

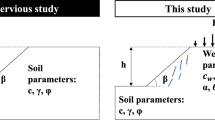

Non-uniform rational B-spline (NURBS) curves are combined with the Kriging model to present a prediction method of the rail grinding profile for a grinding train. As a worn rail profile is a free-form curve, the parameterized model of a rail profile is constructed by using the cubic NURBS curve. Taking the removed area of the rail profile cross-section by grinding as the calculation index of the grinding amount, the grinding amount calculation model of a grinding wheel is established based on the area integral formula of the cubic NURBS curve. To predict the grinding amount of a grinding wheel in different modes, a Kriging model of the grinding amount is constructed, taking the travel speed of a grinding train, the grinding angle and grinding pressure of a grinding wheel as the variables, and considering the grinding amount of a grinding wheel as the response. On this basis, the prediction method of the rail grinding profile is presented based on the order-forming mechanisms. The effectiveness of this method is verified based on a practical application.

摘要

铁路钢轨打磨可以改善车辆运行质量, 延长钢轨使用寿命。 为了保证钢轨打磨后可以获得预定的打磨目标廓形, 需要在打磨之前对钢轨打磨廓形进行预测, 为打磨施工中打磨模式的优选提供依据。 本文设计了一种基于 NURBS-Kriging 模型的钢轨打磨廓形预测方法, 实现了不同打磨模式下钢轨打磨廓形的预测。 具体包括: 考虑磨损钢轨断面廓形为自由曲线, 应用三次 NURBS 曲线构建了钢轨廓形的参数化模型; 基于三次 NURBS 曲线面积精算公式, 设计钢轨打磨量的计算模型; 为预测单个砂轮的打磨量, 将钢轨断面打磨面积作为打磨量衡量指标, 以打磨角度、 打磨压力和打磨速度三个打磨参数为变量, 以打磨面积为响应量, 构建单砂轮打磨量的 Kriging 模型; 根据钢轨打磨顺序成形原理, 提出基于 NURBS-Kriging 模型的钢轨打磨廓形预测方法, 并通过工程应用验证了该方法的有效性。

Similar content being viewed by others

References

SCHOECH W. Development of rail grinding strategies in Europe [C]// Rail Achieving Growth: Conference Proceedings. Melbourne: Railway Technical Society of Australasia: Engineers Australia, 2006: 95–100.

SCHOECH W. Rail maintenance at the core of vehicle rail interaction [C]// CORE 2008: Rail, the Core of Integrated Transport. Perth: Railway Technical Society of Australasia, 2008: 189–197.

HUANG Yu-bin, WANG Wen-jian, GUO Jun, LIU Qi-yue. Effect of asymmetrical rail grinding on running performance of vehicles [J]. Journal of Railway Science and Engineering, 2015, 12(2): 264–268. (in Chinese)

DEVADOSS R, CHATTOPADHYAY G, MANDAL N K, SROBA P, TURNER M, CREESE G. Rail grinding quality assurance based on profile correction and RCF control [C]// CORE 2010: Rail, Rejuvenation and Renaissance. Wellington: Railway Technical Society of Australasia: Engineers Australia, 2010: 8–15.

MA Yue-wei, REN Ming-fa, HU Guang-hui, TIAN Chang-hai. Optimal analysis on rail pre-grinding profile in high-speed railway [J]. Journal of Mechanical Engineering, 2012(8): 90–97. (in Chinese)

JIA Jin-zhong, SI Dao-lin. Target profile of rail grinding for small radius curve of Shuohuang railway [J]. China Railway Science, 2014(4): 15–21. (in Chinese)

XIAO Jie-lin, LIU Xue-yi. Design method of rail asymmetric silhouette [J]. Journal of Southwest Jiaotong University, 2010, 45(3): 361–365. (in Chinese)

REAL J, SALVADOR P, MONTALBAN L, BUENO M. Determination of rail vertical profile through inertial methods [J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail, Rapid Transit, 2010, 30(1): 1–10.

PIERINGER A, KROPP W, THOMPSON D J. Investigation of the dynamic contact filter effect in vertical wheel/rail interaction using a 2D and a 3D non-Hertzian contact model [J]. Wear, 2011, 271(1, 2): 328–338.

ZHANG Qin, CUI Xiao-lu, CHEN Guan-xiong, ZHOU Zhong-rong. Thermal-mechanical coupling analysis in rain grinding [J]. Journal of the China Railway Society, 2015, 37(5): 78–82. (in Chinese)

NIE Meng, LI Jian-yong, SHEN Hai-kuo, WANG Heng, ZHI Shao-dan, LI Hai-bin. Modeling, simulation of temperature in process of rail grinding operation [J]. China Railway Science, 2013(10): 89–93. (in Chinese)

LIU Yue-ming, LI Jian-yong, CAI Yong-lin, NIE Meng. Current state and development trend of rail grinding technology [J]. China Railway Science, 2014, 35(4): 29–37. (in Chinese)

GU Kai-kai, WANG Wen-jian, GUO Jun, LIU Qi-yue. Tribological simulation experiment of interactions between rail and grinding stone [J]. Tribology, 2015, 35(2): 154–159. (in Chinese)

ZHI Shao-dan, LI Jian-yong, FAN Wen-gang, SHEN Hai-kuo, WANG Heng. Research on Contact Line Model for Rail Grinding [J]. Journal of the China Railway Society, 2013, 35(10): 94–99. (in Chinese)

ZHI Shao-dan, LI Jian-yong, CAI Yong-lin, SHEN Hai-kuo, NIE Meng. Mechanisms of rail grinding patterns based on standard rail profile [J]. Journal of Central South University: Science and Technology, 2015, 46(6): 2027–2035. (in Chinese)

ZHI Shao-dan, LI Jian-yong, LIU Yue-ming, NIE Meng. Rail grinding mechanism based on grain cutting model [J]. China Railway Science, 2015(1): 33–39. (in Chinese)

DENG Pei-sen, CHEN Shao-ping, SHEN Jun-cheng. An algorithm for computing integral values with cubic NURBS curve boundaries and its application [J]. Journal of Wuhan University of Technology (Transportation Science & Engineering), 2014(3): 652–657. (in Chinese)

ZHANG Yong, LIN Gao, HU Zhi-qiang, LIU Jun. Isogeometric analysis for elliptical waveguide eigenvalue problems [J]. Journal of Central South University, 2013, 20: 105–113.

ZHAO Xuan-Yi, ZHU Chun-Gang. Injectivity of NURBS curves [J]. Journal of Computational and Applied Mathematics, 2016, 302: 129–138.

KLINKEL S, CHEN L, DORNISCH W. A NURBS based hybrid collocation–Galerkin method for the analysis of boundary represented solids [J]. Computer Methods in Applied Mechanics and Engineering, 2015, 284: 689–711.

DODGSON N A, KOSINKA J. Can local NURBS refinement be achieved by modifying only the user interface? [J]. Computer-Aided Design, 2016, 71: 28–38.

ZENG Wei, YANG Yue, XIE Huan, TONG Lin-jun. CF-Kriging surrogate model based on the combination forecasting method [J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2016, 230(18): 3274–3284.

Transport bureau of Chinese national railway corporation. Management measures of high speed railway rail grinding [EB/OL]. [2016-02-20]. http://wenku.baidu.com/link?url=FBnUiAGtG8UIhIoYvHTfIwWxP6AkTmRhJoFKkMUd_fhL-I8IuzPq0apHZBmbpbKzTAd0QAbXdpOA8E-vLaG_iz4lAhnE2Jy-orX0MKsx_C3. (in Chinese)

YANG Yue, ZENG Wei, QIU Wen-Sheng, WANG Ting. Optimization of the suspension parameters of a rail vehicle based on a virtual prototype Kriging surrogate model [J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail, Rapid Transit, 2016, 230(8): 1890–1898.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51405516) supported by the National Natural Science Foundation of China; Project(2015JJ2168) supported by the Natural Science Foundation of Hunan Province, China

Rights and permissions

About this article

Cite this article

Yang, Y., Qiu, Ws., Zeng, W. et al. A prediction method of rail grinding profile using non-uniform rational B-spline curves and Kriging model. J. Cent. South Univ. 25, 230–240 (2018). https://doi.org/10.1007/s11771-018-3732-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-018-3732-9