Abstract

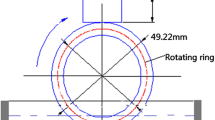

Tribological behavior of Cu−15Ni−8Sn (mass fraction, %) alloy against GCr15 ring under various loads was investigated on a ring-on-block tester in oil lubrication. The results showed that the wear rate increased slowly from 1.7×10−7 to 9.8× 10−7 mm3/mm under the load lower than 300 N, and then increased dramatically to the climax of 216×10−7 mm3/mm under the load over 300 N, which indicated the transition of wear mechanism with the increase of applied load. The wear mechanism mainly was plastic deformation and abrasive wear under the load less than 300 N. As the applied load was more than 300 N, the wear mechanism of Cu−15Ni−8Sn alloy primarily was delamination wear. Besides, the transition can also be confirmed from the different morphologies of worn surface, subsurface and wear debris. It is distinctly indicated that the appearance of flaky debris at the applied load over 300 N may be a critical point for the change of wear mechanism.

Similar content being viewed by others

References

EMGE A, KARTHIKEYAN S, KIM H J, RIGNEY D A. The effect of sliding velocity on the tribological behavior of copper [J]. Wear, 2007, 263(1): 614–618.

STRAFFELINI G, MAINES L, PELLIZZARI M, STRAFFLINI G. Dry sliding wear of Cu-Be alloys [J]. Wear, 2005, 259(1): 506–511.

YIN B, YIN Y, LEI Y, DONG L H, ZHANG Y J. Experimental and density functional studies on the corrosion behavior of the copper-nickel-tin alloy [J]. Chemical Physics Letters, 2011, 509(4): 192–197.

CHEN B, BI Q, YANG J, XIA Y Q, HAO J C. Tribological properties of solid lubricants (graphite, h-BN) for Cu-based P/M friction composites [J]. Tribology international, 2008, 41(12): 1145–1152.

MA X C, HE G Q, HE D H, CHEN C S, HU Z F. Sliding wear behavior of copper- graphite composite material for use in maglev transportation system [J]. Wear, 2008, 265(7): 1087–1092.

KOVALCHENKO A M, FUSHCHICH O I, DANYLUK S. The tribological properties and mechanism of wear of Cu-based sintered powder materials containing molybdenum disulfide and molybdenum diselenite under unlubricated sliding against copper [J]. Wear, 2012, 290: 106–123.

TAKATA N, LEE S H, TSUJI N. Ultrafine grained copper alloy sheets having both high strength and high electric conductivity [J]. Materials Letters, 2009, 63(21): 1757–1760.

CARIS J, LI D, STEPHENS J J, LEWANDONSKI I J. Microstructural effects on tension behavior of Cu-15Ni-8Sn sheet [J]. Materials Science and Engineering A, 2010, 527(3): 769–781.

SCHWARTZ L H, MAHAJAN S, PLEWES J T. Spinodal decomposition in a Cu-9wt%Ni-6wt% Sn alloy [J]. Acta Metallurgica, 1974, 22(5): 601–609.

van HUNNIK E W J, COLIJN J, SCHADE VAN WESTRUM J A F M. Heat treatment and phase inter-relationships of the spray cast Cu−15% Ni−8% Sn alloy [C]// Materials Science Forum. Trans Tech Publications, 1992: 115–124.

KAR N J. Copper-based spinodal alloy bearings: US, 4641976 [P]. 1987−02−10.

CRIBB W R, RATKA J O. Copper spinodal alloys [J]. Advanced Materials & Processes, 2002, 160(11): 27–30.

SINGH J B, CAI W, BELLON P. Dry sliding of Cu−15% Ni−8% Sn bronze: Wear behaviour and microstructures [J]. Wear, 2007, 263(1): 830–841.

MA Wen-lin, LU Jin-jun. Effect of sliding speed on surface modification and tribological behavior of copper-graphite composite [J]. Tribology Letters, 2011, 41(2): 363–370.

CANAKCI A, ARSLAN F. Abrasive wear behaviour of B4C particle reinforced Al2024 MMCs [J]. The International Journal of Advanced Manufacturing Technology, 2012, 63(5−8): 785–795.

HONG E, KAPLIN B, YOU T, SUH M S, KIM Y S, CHOE H. Tribological properties of copper alloy-based composites reinforced with tungsten carbide particles [J]. Wear, 2011, 270(9): 591–597.

WEI M X, WANG S Q, WANG L, CUI X H, CHEN K M. Effect of tempering conditions on wear resistance in various wear mechanisms of H13 steel [J]. Tribology International, 2011, 44(7): 898–905.

DWIVEDI D K. Adhesive wear behaviour of cast aluminium-silicon alloys: overview [J]. Materials & Design, 2010, 31(5): 2517–2531.

MAO Y S, WANG L, CHEN K M, WANG S Q, CUI X H. Tribo-layer and its role in dry sliding wear of Ti-6Al-4V alloy [J]. Wear, 2013, 297(1): 1032–1039.

UTHAYAKUMAR M, ARAVINDAN S, RAJKUMAR K. Wear performance of Al-SiC-B4C hybrid composites under dry sliding conditions [J]. Materials & Design, 2013, 47: 456–464.

TENG Jie, LI Hua-pei, CHEN Gang. Wear mechanism for spray deposited Al-Si/SiCp composites under dry sliding condition [J]. Journal of Central South University, 2015, 22(8): 2875–2882.

ASIH A M S, DING K, KAPOOR A. Modelling rail wear transition and mechanism due to frictional heating [J]. Wear, 2012, 284: 82–90.

WANG Y, ZHANG L, WANG T, HUZ X, CHEN W, FENG C. Effect of sliding velocity on the transition of wear mechanism in (Zr, Cu)95Al5 bulk metallic glass [J]. Tribology International, 2016, 101: 141–151.

ALIDOKHT S A, ABDOLLAH A, SOLEYMANI S, SAEID T, ASSADI H. Evaluation of microstructure and wear behavior of friction stir processed cast aluminum alloy [J]. Materials Characterization, 2012, 63: 90–97.

JISHENG E, GAWNE D T. Influence of lubrication regime on the sliding wear behaviour of an alloy steel [J]. Wear, 1997, 211(1): 1–8.

SUH N P. An overview of the delamination theory of wear [J]. Wear, 1977, 44(1): 1–16.

GONG T, YAO P, XIAO Y, FAN K, TAN H, ZHANG Z, ZHAO L, ZHOU H, DENG M. Wear map for a copper-based friction clutch material under oil lubrication [J]. Wear, 2015, 328: 270–276.

JAHANMIR S, SUH N P. Mechanics of subsurface void nucleation in delamination wear [J]. Wear, 1977, 44(1): 17–38.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2016YFB0301402) supported by the National Key Research and Development Program of China; Project(CSU20151024) supported by the Innovation-driven Plan in Central South University, China

Rights and permissions

About this article

Cite this article

Zhang, Sz., Gan, Xp., Cheng, Jj. et al. Effect of applied load on transition behavior of wear mechanism in Cu−15Ni−8Sn alloy under oil lubrication. J. Cent. South Univ. 24, 1754–1761 (2017). https://doi.org/10.1007/s11771-017-3583-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-017-3583-9