Abstract

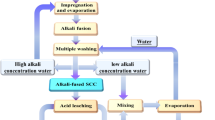

A process was proposed to convert and separate selenium and arsenic in copper anode slime (CAS) by low-temperature alkali fusion process. Central composite design was employed to optimize the effective parameters, in which NaOH/CAS mass ratio, fusion temperature and fusion time were selected as variables, and the conversion ratio of selenium and arsenic as responses. Second-order polynomial models of high significance and 3D response surface plots were constructed to show the relationship between the responses and the variables. Optimum area of >90% selenium conversion ratio and >90% arsenic conversion ratio was obtained by the overlaid contours at NaOH/CAS mass ratio of 0.65-0.75, fusion temperature of 803-823 K and fusion time of 20-30 min. The models are validated by experiments in the optimum area, and the results demonstrate that these models are reliable and accurate in predicting the fusion process.

Similar content being viewed by others

References

HUANG Wang-yin, SU Qing-ping. The situation and development of copper hydrometallurgy [J]. Anhui Chemical, 2011, 37(2): 13–14. (in Chinese)

CHEN Guo-bao, YANG Hong-ying, GUO Jun, LI Xue-jiao. The rougher flotation process of copper anode slime for collecting gold and silver [J]. Precious Metals, 2013, 34(3): 32–33. (in Chinese)

LI Xue-jiao, YANG Hong-ying, TONG Lin-lin, CHEN Guo-bao. Technological mineralogy of copper anode slime [J]. Journal of Northeastern University(Natural Science), 2013, 34(4): 560–561. (in Chinese)

LIU Wei-feng. Study on copper/lead anode slimes treated by alkaline oxidative leaching [D]. Changsha: Central South University, 2011: 120–128. (in Chinese)

GUO Xue-yi, XIAO Cai-mei, ZHONG Ju-ya, TIAN Qing-hua. Behaviors of precious metals in process of copper anode slime treatment [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 990–998. (in Chinese)

COOPER W C. The treatment of copper refinery anode slimes [J]. JOM, 1990, 42(8): 45–49.

YASIN K, GULDEM K, SERVET T. An investigation of copper and selenium recovery from copper anode slimes [J]. International Journal of Mineral Processing, 2013, 124: 75–82.

HOFFMANN J E. Recovering selenium and tellurium from copper refinery slimes [J]. Journal of the Minerals Metals Materials Society, 1989, 41(7): 33–38.

SYED S. Recovery of gold from secondary sources—A review [J]. Hydrometallurgy, 2012, 115: 30–51.

LI Dong, GUO Xue-yi, XU Zhi-peng, TIAN Qing-hua, FENG Qi-ming. Leaching behavior of metals from copper anode slime using an alkali fusion-leaching process [J]. Hydrometallurgy, 2015, 157: 9–12.

LIU Wei-feng, YANG Tian-zu, ZHANG Du-chao, CHEN Lin, LIU You-nian. Pretreatment of copper anode slime with alkaline pressure oxidative leaching [J]. International Journal of Mineral Processing, 2014, 128: 48–54.

LU Dian-kun, CHANG Yong-feng, YANG Hong-ying, XIE Feng. Sequential removal of selenium and tellurium from copper anode slime with high nickel content [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(4): 1307–1314.

TANG Mo-tang, TANG Chao-bo, CHEN Yong-ming, YANG Jian-guang, YANG Sheng-hai, HE Jing, OU Zhao. A promising low carbon clean metallurgical method: low-temperature molten salt metallurgy of heavy metal [J]. China Nonferrous Metallurgy, 2010, (4): 49–53. (in Chinese)

HU Yu-jie, TANG Chao-bo, TANG Mo-tang, YANG Jian-guang, CHEN Yong-ming, YANG Sheng-hai, HE Jing. A clean and green process of low-temperature for smelting of secondary lead [J]. Nonferrous Metals(Extractive Metallurgy) 2013(8): 1–4. (in Chinese)

GUO Xue-yi, LIU Jing-xin, TIAN Qing-hua. Elemental behavior of multi-component metal powders from waste printed circuit board during low-temperature alkaline smelting [J]. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1757–1763. (in Chinese)

LIU Jing-xin, GUO Xue-yi, TIAN Qing-hua, LI Dong. Separation and extraction of amphoteric metals from waste printed circuit board powders by low-temperature alkaline smelting [J]. Journal of University of Science and Technology Beijing, 2014, 36(7): 875–879. (in Chinese)

PODSTAWCZYK D, WITEK-KROWIAK A, DAWIEC A, BHATNAGAR A. Biosorption of copper (II) ions by flax meal: Empirical modeling and process optimization by response surface methodology (RSM) and artificial neural network (ANN) simulation [J]. Ecological Engineering, 2015, 83: 364–379.

AKALIN M K, TEKIN K, AKYUZ M, KARAGOZ S. Sage oil extraction and optimization by response surface methodology [J]. Industrial Crops and Products, 2015, 76: 829–835.

BOX G E P, WILSON K B. On the experimental attainment of optimum conditions [J]. Journal of the Royal Statistical Society, Series B (Methodological), 1951, 13(1): 1–45.

BOX G E P, HUNTER J S. Multi-factor experimental designs for exploring response surfaces [J]. The Annals of Mathematical Statistics, 1957, 28(1): 195–241.

KHURI A I, MUKHOPADHYAY S. Response surface methodology [J]. Wiley Interdisciplinary Reviews: Computational Statistics, 2010, 2(2): 128–149.

ZHANG Xian, WANG Ri-jie, YANG Xiao-xia, YU Jin-gang. Central composite experimental design applied to the catalytic aromatization of isophorone to 3, 5-xylenol [J]. Chemometrics and Intelligent Laboratory Systems, 2007, 89(1): 45–47.

LIN Y C, TSAO C C, HSU C Y, HUNG S K, WEN D C. Evaluation of the characteristics of the microelectrical discharge machining process using response surface methodology based on the central composite design [J]. The International Journal of Advanced Manufacturing Technology, 2012, 62(9-12): 1013–1014.

OBENG D P, MORREL S, NAPIER-MUNN T J. Application of central composite rotatable design to modelling the effect of some operating variables on the performance of the three-product cyclone [J]. International Journal of Mineral Processing, 2005, 76(3): 181–192.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51234009) supported by the National Natural Science Foundation of China; Project(2014DFA90520) supported by International Cooperation Program of Ministry of Science of China; Project(2013A100003) supported by the Production, Teaching and Research Program of Guangdong Province, China

Rights and permissions

About this article

Cite this article

Guo, Xy., Xu, Zp., Tian, Qh. et al. Optimization on selenium and arsenic conversion from copper anode slime by low-temperature alkali fusion process. J. Cent. South Univ. 24, 1537–1543 (2017). https://doi.org/10.1007/s11771-017-3558-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-017-3558-x