Abstract

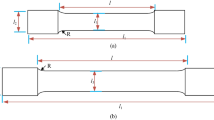

An elasto-visco-plastic constitutive model incorporating the craze damage behavior was developed for the polypropylene (PP), by using the plastic failure model applied for the concrete, to capture the craze yielding and stress-whitening phenomena. In addition, the developed constitutive model was implemented into finite element codes in Abaqus to simulate the tensile deformation. The standard uniaxial tensile tests were carried out. The stress−strain curves from the uniaxial tensile tests show that the stress keeps decreasing after yielding and the yield stress rises with the increasing of the strain rate. It is worth noting that the craze damage is more visible with higher strain rate. The stress-whitening can be seen clearly around the fracture. The uniaxial tensile tests using specially designed specimen with circular holes weakening were performed for the validation of the developed model. The simulation results of the tensile deformation of the hole-weakened specimen suggest that the stress-whitening could be attributed to the equivalent visco-plastic strain. By comparing between the simulation analysis and the experimental results, the proposed model can describe the stress whitening phenomenon with good accuracy.

Similar content being viewed by others

References

FLORENCE R, SHERMAN K. Trends driving design and materials changes in the instrument panel system [J]. SAE Technical Paper 970445, 1997, doi: 10.4271/970445.

SERBAN D A, WEBER G, MARSAVINA L, SILBERSCHIMIDT V V, HUFENBACH W. Tensile properties of semi-crystalline thermoplastic polymers: Effects of temperature and strain rates [J]. Polymer Testing, 2013, 32(2): 413–425.

HUANG J, RODRIGUEZ D. The effect of carbon nanotube orientation and content on the mechanical properties of polypropylene based composites [J]. Materials and Design, 2014, 55: 653–663.

RIO T G, SALAZAR A, RODRIGUEZ J. Effect of strain rate and temperature on tensile properties of ethylene-propylene block copolymers [J]. Materials and Design, 2012, 42: 301–307.

REIS J M L, PACKECO L J, da COSTA MATTOS H S. Tensile behavior of post-consumer recycled high-density polyethylene at different strain rates [J]. Polymer Testing, 2013, 32(2): 338–342.

NUNES L C S, REIS J M L, da COSTA MATTOS H S. Parameters identification of polymer concrete using a fracture mechanics test method and full-field measurements [J]. Engineering Fracture Mechanics, 2011, 78(17): 2957–2965.

BALIEUA R, LAUROA F, BENNANIA B, MOTTOLA E. A fully coupled elastoviscoplastic damage model at finite strains for mineral filled semi-crystalline polymer [J]. International Journal of Plasticity, 2013, 51: 241–270.

TANG C Y, TSUI C P, SHEN W, LI C C, PENG L H. Modelling of non-linear stress-strain behaviour of HIPS with craze damage in tensile loading-unloading process [J]. Polymer Testing, 2000, 20(1): 15–27.

ZARIA F, NAIT-ABDELAZIZA M, GLOAGUENB J M, LEFEBVREB J M. Modelling of the elasto-viscoplastic damage behaviour of glassy polymers [J]. International Journal of Plasticity, 2008, 24(6): 945–965.

SELL C G, HIVER J M, DAHOUN A. Experimental characterization of deformation damage in solid polymers under tension, and its interrelation with necking [J]. International Journal of Solids and Structures, 2002, 39(13, 14): 3857–3872.

BROWM E N, RAEP J, ORLER E B. The influence of temperature and strain rate on the constitutive and damage responses of polychlorotrifluoroethylene (PCTFE, Kel-F81) [J]. Polymer, 2006, 47(21): 7506–7518.

JIANG Bing-yan, HU Jian-liang, LI Jun, LIU X C. Ultrasonic plastification speed of polymer and its influencing factors [J]. Journal of Central South University, 2012 (19): 380–383.

SCHOBG M, BIEROEL C, GRELLMANN W, MECKLENBURG T. Mechanical behavior of glass-fiber reinforced thermoplastic materials under high strain rates [J]. Polymer Testing, 2008, 27(7): 893–900.

MULLIKEN A D, BOYCE M C. Mechanics of the rate-dependent elastic-plastic deformation of glassy polymers from low to high strain rates. [J]. International Journal of Solids and Structures, 2006, 43(5): 1331–1356.

KILLIAN H G, ENDERLE H F, UNSELD K. The use of the van der Waals model to elucidate universal aspects of structure-property relationships in simply extended dry and swollen rubbers [J]. Colloid & Polymer Science, 1986, 264(10): 866–876.

MARLOW R S. A general first-invariant hyperelastic constitutive Model, in Constitutive Models for Rubber III [M]. London: Balkema Publishers, 2003.

OGDEN R W. Large deformation isotropic elasticity-On the correlation of theory and experiment for incompressible tuberlike solids [J]. Proceedings of the Royal Society A, 1972, 326(1567): 565–584.

RIVLIN R S, SAUNDERS D W. Large elastic deformations of isotropic materials. VII. Experiments on the deformation of rubber [J]. Philosophical Transactions of the Royal Society A, 1951, 251–288.

NUNES L C S, DIAS F W R, da COSTA MATTOS H S. Mechanical behavior of polytetrafluoroethylene in tensile loading under different strain rates [J]. Polymer Testing, 2011, 30(7): 791–796.

SERBAN D A, MARSAVINA L, SILBERSCHMIDT V. Behaviour of semi-crystalline thermoplastic polymers: Experimental studies and simulations [J]. Computational Materials Science, 2012, 52(1): 139–146.

DUNNE F, PETRINIC N. Introduction to computational plasticity [M]. Oxford: Oxford University Press, 2006.

REES D W A. Basic engineering plasticity [M]. Elsevier, 2006.

Abaqus Analysis User’s Manual [S].

ROZANSKI A, GALESKI A. Plastic yielding of semicrystalline polymers affected by amorphous phase [J]. International Journal of Plasticity, 2013, 41: 14–29.

HONG K, RASTOGI A, STROBL G. A Model treating tensile deformation of semicrystalline polymers: Quasi-static stress-strain relationship and viscous stress determined for a sample of Polyethylene [J]. Macromolecules, 2004, 37(26): 10165–10173.

LIN J, SHENOGIN S, NAZARENKO S. Oxygen solubility and specific volume of rigid amorphous fraction in semicrystalline poly(ethylene terephthalate) [J]. Polymer, 2002, 43(17): 4733–4743.

PAWLAK A, GALESKI A, ROZANSKI A. Cavitation during deformation of semicrystalline polymers [J]. Progress in Polymer Science, 2014, 39(5): 921–958.

BARTCZAK Z, MORAWIEC J, GALESKI A. Structure and properties of isotactic polypropylene oriented by rolling with side constraints [J]. Journal of Applied Polymer Science, 2002, 86(6): 1413–1425.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51275185) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Gui, Zx., Hu, X. & Wang, Zj. An elasto-visco-plastic constitutive model of polypropylene incorporating craze damage behavior and its validation. J. Cent. South Univ. 24, 1263–1268 (2017). https://doi.org/10.1007/s11771-017-3530-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-017-3530-9