Abstract

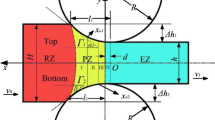

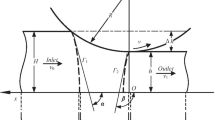

In order to study the distribution of equivalent and shear strain of aluminum alloy plate during snake hot rolling, several coupled thermo-mechanical finite element models (FEM) are established. Effects of speed ratio and offset distance on strain distribution of the plate are analyzed. The length of cross shear zone is defined to have a better understanding of the deformation characteristic in cross shear zone, which is the essential difference from symmetrical rolling in deformation zone. The results show that the equivalent strain and shear strain of lower part both increase with the increase of speed ratio, while the upper part decreases; the equivalent strain through the whole thickness decreases with ascending offset distance, while the shear strain of lower part increases. The length of cross shear zone quickly increases with ascending speed ratio and slightly decreases with ascending offset distance. The “positive” and “negative” cross shear zones are formed with the increase of speed ratio and offset distance, respectively. The value of the sensitivity coefficient of speed ratio is an order of magnitude bigger than the offset distance. However, the shear strain at center point increases with the ascending speed ratio and offset distance for different mechanism. As speed ratio increases, the asymmetry of the distribution of equivalent is becoming larger and the shear strain is generated in the same direction in cross shear zone. The FEM results agree well with experimental results.

Similar content being viewed by others

References

LI Xing-dan. Development of commercial aircraft aluminum alloy structural materials [J]. Shanghai Nonferrous Metals, 1994, 15(3): 160–168. (in Chinese)

YANG Shi-de. Introduction of asymmetric aluminum hot rolling and mill [J]. World Nonferrous Metals, 2010(2): 47. (in Chinese)

LIN Z C, SHEN C C. A rolling process two-dimensional finite element model analysis [J]. Finite Elements in Analysis and Design, 1997, 26(2): 143–160.

TIMOTHY S P, YIU H L, FINE J M, RICKS R A. Simulation of single pass of hot rolling deformation of aluminium alloy by plane strain compression [J]. Materials Science and Technology, 1991, 7(3): 255–263.

DUAN X, SHEPPARD T. Three-dimensional thermal mechanical coupled simulation during hot rolling of Aluminium alloy 3003 [J]. International Journal of Mechanical Sciences, 2002, 44(10): 2155–2172.

YANG H, WANG M, GUO L G, SUN Z C. 3D coupled thermo-mechanical FE modeling of blank size effects on the uniformity of strain and temperature distributions during hot rolling of titanium alloy large rings [J]. Computational Materials Science, 2008, 44(2): 611–621.

DAVENPORT S B, HIGGINSON R L, SELLARS C M. The effect of strain path on material behaviour during hot rolling of FCC metals [J]. Philosophical Transactions of the Royal Society of London A: Mathematical, Physical and Engineering Sciences, 1999, 357(1756): 1645–1661.

SERAJZADEH S, TAHERI A K, NEJATI M, IZADI J, FATTAHI M. An investigation on strain inhomogeneity in hot strip rolling process [J]. Journal of Materials Processing Technology, 2002, 128(1): 88–99.

MOUSAVI S, EBRAHIMI S M, MADOLIAT R. Three dimensional numerical analyses of asymmetric rolling [J]. Journal of Materials Processing Technology, 2007, 187: 725–729.

ZUO Fang-qing, JIANG Jian-hua, SHAN Ai-dang, FANG Jian-min, ZHANG Xing-yao. Shear deformation and grain refinement in pure Al by asymmetric rolling [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(4): 774–777.

YUAN Fu-shun, SUN Ji-quan. Deformation analysis in deformation zone of asymmetrical rolling with different roll velocity [J]. Shandong Metallurgy, 2010, 32(6): 25–27. (in Chinese)

LIU Jie, KAWALLA R. Influence of asymmetric hot rolling on microstructure and rolling force with austenitic steel [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: s504–s511.

ZHANG Tao, WU Yun-xin, GONG Hai, ZHENG Xi-zhao, JIANG Shao-song. Effects of rolling parameters of snake hot rolling on strain distribution of aluminum alloy 7075-TNMSC [J]. The Chinese Journal of Nonferrous Metals, 2015, 24(7): 2150–2156.

CHO S H, YOO Y C. Hot rolling simulations of austenitic stainless steel [J]. Journal of Materials Science, 2001, 36(17): 4267–4272.

SHAHANI A R, SETAYESHI S, NODAMAIE S A, ASADI M A, REZAZE S. Prediction of influence parameters on the hot rolling process using finite element method and neural network [J]. Journal of Materials Processing Technology, 2009, 209(4): 1920–1935.

LIU Y, LIN J. Modelling of microstructural evolution in multipass hot rolling [J]. Journal of Materials Processing Technology, 2003, 143: 723–728.

ZHOU S X. An integrated model for hot rolling of steel strips[J]. Journal of Materials Processing Technology, 2003, 134(3): 338–351.

AHMED H, WELLS M A, MAIJER D M, HOWES B J, WINDEN M R. Modelling of microstructure evolution during hot rolling of AA5083 using an internal state variable approach integrated into an FE model [J]. Materials Science and Engineering A, 2005, 390(1): 278–290.

DING Han-lin, HIRAI K, HOMMA T, KAMADO S. Numerical simulation for microstructure evolution in AM50 Mg alloy during hot rolling J]. Computational Materials Science, 2010, 47(4): 919–925.

ZHANG Tao, WU Yun-xin, GONG Hai, ZHENG Xi-zhao, JIANG Shao-song. Bending analysis and control of rolled plate during snake hot rolling [J]. Journal of Central South University, 2015, 22: 2463–2469.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51405520) supported by the National Natural Science Foundation of China; Project(2012CB619505) supported by National Basic Research Program of China

Rights and permissions

About this article

Cite this article

Zhang, T., Wu, Yx., Gong, H. et al. Analysis of strain variation in cross shear zone of plate during snake hot rolling. J. Cent. South Univ. 24, 296–302 (2017). https://doi.org/10.1007/s11771-017-3430-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-017-3430-z