Abstract

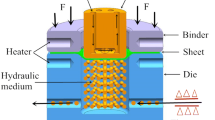

Hot granule medium pressure forming (HGMF) is a technology in which heat-resistant granules are used to replace liquids or gases in existing flexible-die forming technology as pressure-transfer medium. Considering the characteristic of granule medium that seals and loads easily, the technology provides a new method to realize the hot deep-drawing forming on high strength aluminum alloy sheet. Based on the pressure-transfer performance test of granule medium and the material performance test of AA7075-T6 sheet, plastic mechanics analysis is conducted for the areas, such as the flange area, force-transfer area and free deforming area, of cylindrical parts deep-drawn by HGMF technology, and the function relation of forming pressure is obtained under the condition of nonuniform distribution of internal pressure. The comparison between theoretical result and experimental data shows that larger deviation occurs in the middle and later period of forming process, and the maximum theoretical forming force is less than the experimental value by 24.6%. The variation tendency of the theoretical thickness curve is close to the practical situation, and the theoretical value basically agrees well with experimental value in the flange area and the top area of spherical cap which is in the free deforming area.

Similar content being viewed by others

References

POURBOGHRAT F, VENKATESAN S, CARSLEY J E. LDR and hydroforming limit for deep drawing of AA5754 aluminum sheet [J]. Journal of Manufacturing Processes, 2013, 15(4): 600–615.

PALUMBO G, PICCININNI A. Numerical-experimental investigations on the manufacturing of an aluminium bipolar plate for proton exchange membrane fuel cells by warm hydroforming [J]. The International Journal of Advanced Manufacturing Technology, 2013, 69(1/2/3/4): 731–742.

LANG Li-hui, DU Ping-mei, LIU Bao-sheng, CAI Gao-can, LIU Kang-ning. Pressure rate controlled unified constitutive equations based on microstructure evolution for warm hydroforming [J]. Journal of Alloys and Compounds, 2013, 574: 41–48.

GHOSH M, MIROUX A, WERKHOVEN R J, BOLT P J, KESTENS L A I. Warm deep-drawing and post drawing analysis of two Al-Mg-Si alloys [J]. Journal of Materials Processing Technology, 2014, 214: 756–766.

ABU-FARHA F, HECTOR L, KRAJEWSKI P. Forming limit curves for the aa5083 alloy under quick plastic forming conditions [C]// SAE 2011 World Congress and Exhibition. Detroit, MI, United States, 2011: 4–8.

SHAO Zong-ke, HUANG Zhong-guo, JIN Shun-yao, LEI Kun, YUAN Qing-hua. Influence of single-direct and direct-reverse SPF on properties of TC4 alloy negative-angle parts [J]. Journal of Aeronautical Materials, 2013, 33(1): 1–6. (in Chinese)

LIANG H J, WU X W, WANG Y, JIN Q L, MA Z L, FENG S S. Research on quick superplastic forming for aluminium alloy sheet [J]. Materials science forum, 2013, 735: 301–306.

BARIANI P F, SALVADOR M, LUCCHETTA G. Development of a test method for the rheological characterization of polymers under the injection molding process conditions [J]. Journal of Materials Processing Technology, 2007, 191(1/2/3): 119–122.

BARIANI P F, BRUSCHI S, GHIOTTI A, LUCCHETTA G. An approach to modelling the forming process of sheet metal-polymer composites [J]. CIRP Annals-Manufacturing Technology, 2007, 56(1): 261–264.

LIU Jiang-guang, WANG Zhong-jin. Prediction of wrinkling and fracturing in viscous pressure forming (VPF) by using the coupled deformation sectional finite element method [J]. Computational Materials Science, 2010, 48: 381–389.

GRÜNER M, MERKLEIN M. Numerical simulation of hydro forming at elevated temperatures with granular material used as medium compared to the real part geometry [J]. International Journal of Material Forming, 2010, 3(1): 279–282.

GRÜNER M, MERKLEIN M. Consideration of elastic tool deformation in numerical simulation of hydroforming with granular material used as a medium [J]. Key Engineering Materials, 2011, 473: 707–714.

LI Peng-li, ZHANG Zhi, ZENG Yuan-song. Studty on titanium alloy spinner based on solid granules medium forming [J]. Forging & Stamping Technology, 2012, 37(5): 60–63. (in Chinese)

DONG Guo-jiang, ZHAO Chang-cai, CAO Miaoyan. Flexible-die forming process with solid granule medium on sheet metal [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(9): 2666–2677.

CAO Miao-yan, ZHAO Chang-cai, WU Li-jun, DONG Guo-jiang. Lubricant research on SGMF of magnesium alloy sheet [J]. Advanced Materials Research, 2013, 675: 311–316.

DONG Guo-jiang, ZHAO Chang-cai, CAO Miao-yan. Process of back pressure deep drawing with solid granule medium on sheet metal [J]. Journal of Central South University, 2014, 21(7): 2617–2626.

DONG Guo-jiang, ZHAO Chang-cai, PENG Ya-xin, LI Ying. Hot granules medium pressure forming process of AA7075 conical parts [J]. Chinese Journal of Mechanical Engineering, 2015, 28(3): 580–591.

XIAO Jing-rong, JIANG Kui-hua. Stamping technology [M]. Beijing: China Machine Press, 1999: 72–89. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Projects(51305386, 51305385) supported by the National Natural Science Foundation of China; Project(E2013203093) supported by the Natural Science Foundation of Hebei Province, China

Rights and permissions

About this article

Cite this article

Dong, Gj., Yang, Zy., Zhao, Jp. et al. Stress-strain analysis on AA7075 cylindrical parts during hot granule medium pressure forming. J. Cent. South Univ. 23, 2845–2857 (2016). https://doi.org/10.1007/s11771-016-3348-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-016-3348-x