Abstract

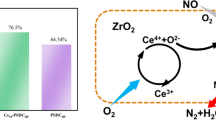

Ultrasonic treatment and hydrothermal method were applied in the traditional homogeneous precipitation for nano-TiO2 preparation, which was used as carrier material for the production of honeycomb selective catalytic reduction (SCR) catalyst. The influence rules of the two improved methods on characterization of TiO2 samples, denitration activity and mechanical strength of honeycomb SCR catalyst samples were mainly focused on. The results indicate that the specific surface area, particle size and uniformity of TiO2 samples are significantly improved by both of the ultrasonic and hydrothermal treatments compared with the traditional homogeneous precipitation. Also, the denitration activities of catalyst samples are enhanced by the two improved methods (the NO x reduction ratio increases from 88.89% to 95.45% by ultrasonic homogeneous precipitation process, and to 94.12% by hydrothermal homogeneous precipitation process). On the other hand, because of good spherical shape and high particle distribution of TiO2 sample from hydrothermal homogeneous precipitation process, the corresponding honeycomb catalyst samples get the best mechanical strength, which is even higher than that of the reference sample from commercial nano-TiO2. So, it is concluded that the hydrothermal homogeneous precipitation can be a feasible and effective preparation method of TiO2 carrier for the honeycomb SCR catalyst production.

Similar content being viewed by others

References

ZHENG Yuan-jing, JENSEN A D, JOHNSSON J E. Deactivation of V2O5-WO3-TiO2 SCR catalyst at a biomass-fired combined heat and power plant [J]. Applied Catalysis B: Environmental, 2005, 60: 253–264.

KRÖCHER O, ELSENER M. Chemical deactivation of V2O5/WO3–TiO2 SCR catalysts by additives and impurities from fuels, lubrication oils, and urea solution I: Catalytic studies [J]. Applied Catalysis B: Environmental, 2008, 75: 215–227.

GUO Xiao-yu, BARTHOLOMEW C, HECKER W, BAXTER L L. Effects of sulfate species on V2O5/TiO2 SCR catalysts in coal and biomass-fired systems [J]. Applied Catalysis B: Environmental, 2009, 92: 30–40.

CASTELLINO F, RASMUSSEN S B, JENSEN A D, JOHNSSON J E, FEHRM A N N R. Deactivation of vanadia-based commercial SCR catalysts by polyphosphoric acids [J]. Applied Catalysis B: Environmental, 2008, 83: 110–122.

THEINNOI K, TSOLAKIS A, SITSHEBO S, CRACKNELL R F, CLARK R H. Fuels combustion effects on a passive mode silver/alumina HC-SCR catalyst activity in reducing NOX [J]. Chemical Engineering Journal, 2010, 158: 468–473.

MA Zi-ran, WENG Duan, WU Xiao-dong, SI Zhi-chun, WANG Bin. A novel Nb-Ce/WOX-TiO2 catalyst with high NH3-SCR activity and stability [J]. Catalysis Communications, 2012, 27: 97–100.

CHEN Xia, ZHANG Jun-feng, HUANG Yan, TONG Zhi-quan, HUANG Ming. Catalytic reduction of nitric oxide with carbon monoxide on copper-cobalt oxides supported on nano-titanium dioxide [J]. Journal of Environmental Sciences, 2009, 21: 1296–1301.

GINSBERGA T, MODIGELLA M, WILSMANNB W. Thermochemical characterisation of the calcinations process step in the sulphate method for production of titanium dioxide [J]. Chemical Engineering Research and Design, 2011, 89: 990–994.

TIAN Cong-xue, DU Jian-qiao, CHEN Xin-hong, MA Wei-ping, LUO Zhi-qiang, CHENG Xiao-zhe, HU Hong-fei, LIU Dai-jun. Influence of hydrolysis in sulfate process on titania pigment producing [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: 829–833.

ŠUBRT J, ŠTENGL V, BAKARDJIEVA S, SZATMARY L. Synthesis of spherical metal oxide particles using homogeneous precipitation of aqueous solutions of metal sulfates with urea [J]. Powder Technology, 2006, 169: 33–40.

LATT K K, KOBAYASHI T. TiO2 nanosized powders controlling by ultrasound sol–gel reaction [J]. Ultrasonics Sonochemistry, 2008, 15: 484–491.

GHOWS N, ENTEZARI M H. Ultrasound with low intensity assisted the synthesis of nanocrystalline TiO2 without calcinations [J]. Ultrasonics Sonochemistry, 2010, 17: 878–883.

TIAN Bao-zhu, FENG Che-na, ZHANG Jin-long, MASAKAZU A. Influences of acids and salts on the crystalline phase and morphology of TiO2 prepared under ultrasound irradiation [J]. Journal of Colloid and Interface Science, 2006, 303: 142–148.

OH S W, PARK S, SUN Y. Hydrothermal synthesis of nano-sized anatase TiO2 powders for lithium secondary anode materials [J]. Journal of Power Sources, 2006, 161: 1314–1318.

YIN Heng-bo, WADA Y, KITAMURA T, KAMBE S, MURASAWA S, MORI H, SAKATA T, YANAGIDA S. Hydrothermal synthesis of nanosized anatase and rutile TiO2 using amorphous phase TiO2 [J]. Journal of Materials Chemistry, 2001, 11: 1694–1703.

PUDDU V, MOKAYA R, PUMA G L. Novel one step hydrothermal synthesis of TiO2/WO3 nanocomposites with enhanced photocatalytic activity [J]. Chemical Communications, 2007, 45: 4749–4751.

LIU Qing-ya, LIU Zhen-yu, HUANG Zhang-gen, XIE Guo-yong. A honeycomb catalyst for simultaneous NO and SO2 removalfrom flue gas: Preparation and evaluation [J]. Catalysis Today, 2004, 93–95: 833–837.

SUN Hong, SHU Yun, QUAN Xie, CHEN Shuo, PANG Bo, LIU Zhao-yang. Experimental and modeling study of selective catalytic reduction of NOX with NH3 over wire mesh honeycomb catalysts [J]. Chemical Engineering Journal, 2010, 165: 769–775.

BERETTA A, TRONCONI E, ALEMANY L J, SVACHULA J, FORZATTI P. Effect of morphology of honeycomb SCR catalysts on the reduction of NOX and the oxidation of SO2 [J]. Studies in Surface Science and Catalysis, 1994, 82: 869–876.

SHANG Xue-song, HU Gong-ren, HE Chi, ZHAO Jin-ping, ZHANG Fu-wang, XU Ya, ZHANG Yun-feng, LI Jiang-rong, CHEN Jin-sheng. Regeneration of full-scale commercial honeycomb monolith catalyst (V2O5–WO3/TiO2) used in coal-fired power plant [J]. Journal of Industrial and Engineering Chemistry, 2012, 18: 513–519.

CZEKAJ I, KRÖCHER O, PIAZZESI G. DFT calculations, DRIFT spectroscopy and kinetic studies on the hydrolysis of isocyanic acid on the TiO2-anatase (101) surface [J]. Journal of Molecular Catalysis A: Chemical, 2008, 280: 68–80.

YASHNIK S A, ISMAGILOV Z R, KOPTYUG I V, ANDRIEV SKAYA I P, MATVEEV A A, MOULIJIN J A. Formation of textural and mechanical properties of extruded ceramic honeycomb monoliths: An 1H NMR imaging study [J]. Catalysis Today, 2005, 105: 507–515.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(201031) supported by the Environmental Protection Scientific Research of Jiangsu Province, China; Project(BE2010184) supported by the Technology Support Program of Jiangsu Province—Industrial Parts, China

Rights and permissions

About this article

Cite this article

Yao, J., Zhong, Zp. TiO2 preparation by improved homogeneous precipitation and application in SCR catalyst. J. Cent. South Univ. 23, 2139–2145 (2016). https://doi.org/10.1007/s11771-016-3270-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-016-3270-2